Preparation of supported platinum nano-cluster catalyst and application of supported platinum nano-cluster catalyst in alkane anaerobic dehydrogenation

A platinum nano-catalyst technology, which is applied in the field of noble metal nano-cluster catalysis, can solve the problems of low substrate conversion rate, easy reaction deactivation of catalyst, and insufficient selectivity of target products, so as to achieve high activity and improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

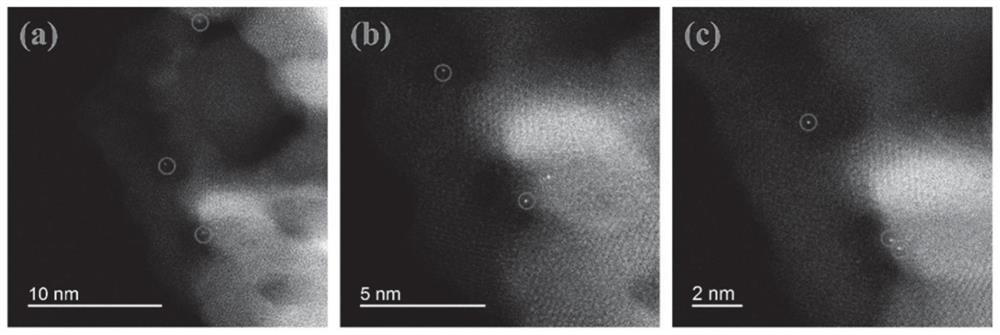

[0032] (1) Dissolve 50 mg of potassium tetrachloroplatinate in 10 mL of ethanol, and then add 80 mg of triphenylphosphine and 40 mg of a thiol ligand. The above solution was stirred at room temperature for 0.5 hours. Afterwards, the solution was spin-dried, washed with n-hexane, dried in a vacuum oven, and dried at 50° C. for 2 hours; diatomic platinum nanoclusters were obtained. figure 1 It is an electron microscope picture of diatomic platinum, from which we can see diatomic nanoclusters.

[0033] (2) Disperse 5mg of diatomic platinum nanoclusters in dedichloromethane or ethanol, and stir at 20°C for 1h; then add 1g of carrier, continue stirring for 6h, centrifuge, and dry, the drying time is 12h, and the drying temperature is 50°C , to obtain the sample Pt obtained after drying 2 / Al 2 o 3 . 150 mg of catalyst was placed in the reaction tube in 30% by volume H 2 / N 2 atmosphere, pretreatment for 90 minutes under the condition of 550°C.

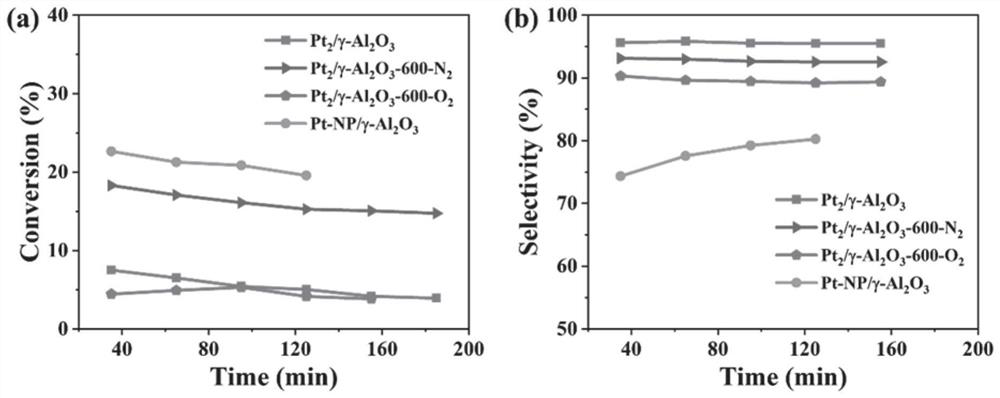

[0034] (3) The above catalys...

Embodiment 2

[0036] (1) Dissolve 50 mg of potassium tetrachloroplatinate in 20 mL of ethanol, and then add 80 mg of thiol ligand. The above solution was stirred at room temperature for 0.5 hours. Then 20 mg of sodium borohydride dissolved in 4 ml of aqueous solution was added and stirred for 6 hours. Afterwards, the solution was spin-dried, washed by adding n-hexane, and dried in a vacuum oven at a drying temperature of 50° C. and a drying time of 6 hours; polyatomic platinum nanoclusters were obtained.

[0037] (2) Disperse 5mg of polyatomic platinum nanoclusters in dedichloromethane or ethanol, stir at 20°C for 1h; then add 1g of carrier Al 2 o 3 , after continuing to stir for 6 hours, centrifuge and dry, the drying time is 12 hours, and the drying temperature is 50° C. to obtain the sample obtained after drying. The obtained catalyst was calcined at 550 ° C for 2 h in a nitrogen atmosphere to obtain the catalyst Pt 25 / Al 2 o 3 . 150 mg of catalyst Pt 25 / Al 2 o 3 Placed in a ...

Embodiment 3

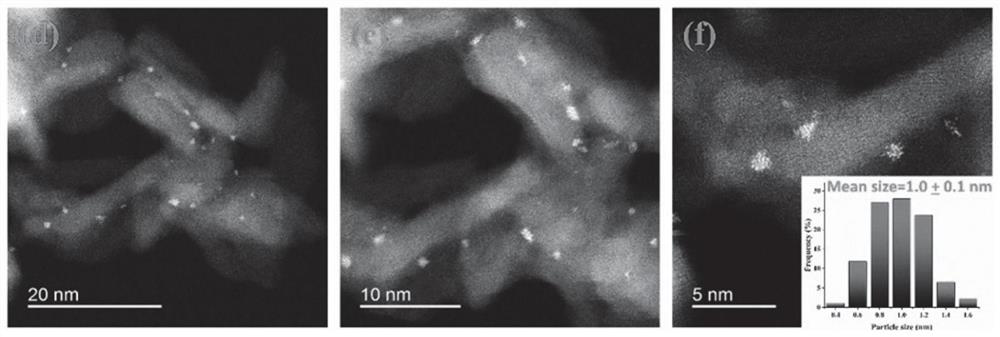

[0040] (1) The sample dried in step (2) of Example 1 was roasted at 600°C for 2h in a nitrogen atmosphere before pretreatment to obtain the catalyst Pt 2 / Al2 o 3 -N 2 -600. 150 mg of catalyst was placed in the reaction tube in 30% by volume H 2 / N 2 atmosphere, pretreatment for 90 minutes under the condition of 550°C. figure 2 It is an electron microscope picture of platinum nanoclusters. It can be seen from the figure that polyatomic nanoclusters have a size of about 1nm and the number of metal platinum atoms is about 25.

[0041] (2) The above catalyst is at 550°C, nitrogen balance, C 3 h 8 and H 2 The ratio is 1:1, the flow rate is 50ml min -1 Under the conditions of reaction, the reaction time is 2 hours. The conversion of propane was 20%, and the selectivity to propylene was 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com