Preparation method of polypropylene foaming sheet material through ultraviolet light radiation crosslinking

A technology of cross-linked polypropylene and foamed sheet, which is applied in the field of preparation of polypropylene foamed sheet and ultraviolet cross-linked polypropylene foamed sheet, can solve the problem of reducing the usability and mechanical properties of materials and failing to prepare foamed sheets. materials, difficult continuous production and other problems, to achieve the effect of low density, low price, good mechanical and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

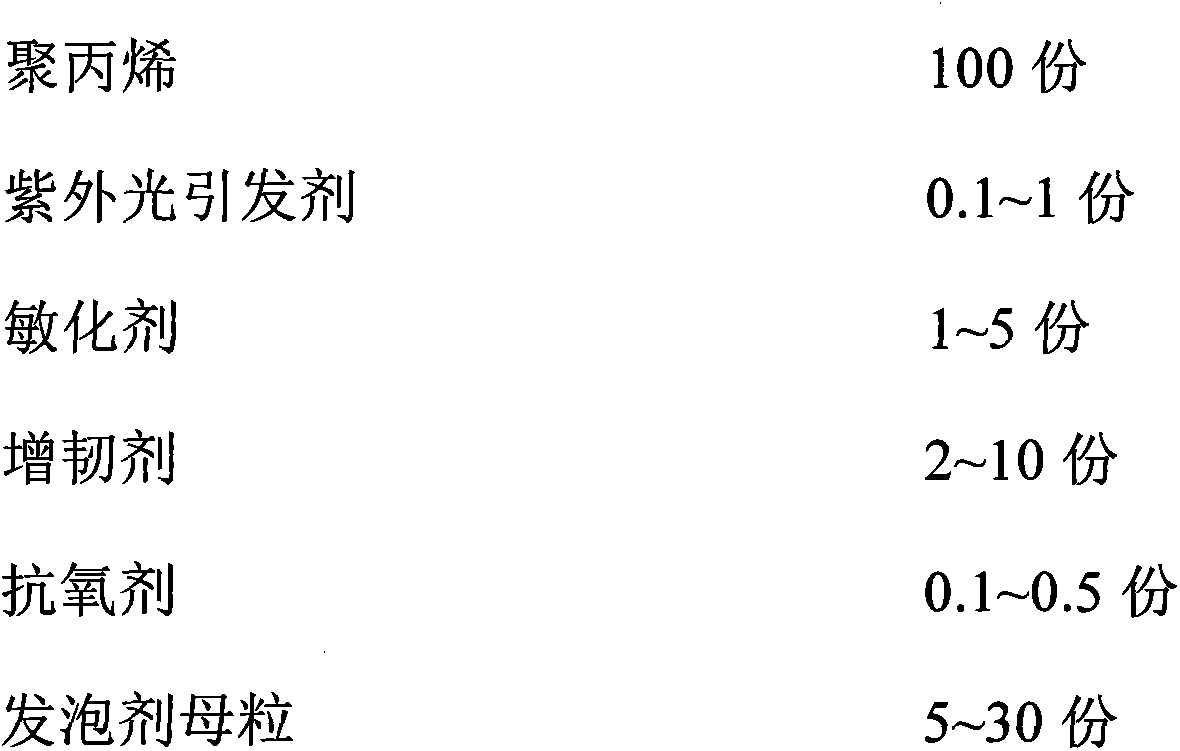

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Weigh 100 parts of polypropylene, 0.2 parts of ultraviolet photoinitiator, 1.6 parts of sensitizer, 10 parts of toughening agent and 0.1 part of antioxidant in parts by mass, and mix them in a high-speed mixer for 10 to 15 minutes , The material temperature is controlled at about 80°C. Then, the homogeneously mixed material is blended, melted and extruded by a twin-screw extruder, and granulated. The extrusion temperature is about 230°C. Take 30 parts of foaming agent masterbatch and mix evenly with the pellets granulated by the twin-screw extruder, carry out non-foaming extrusion on the single-screw extruder, extrude a polypropylene foam sheet with a thickness of 1mm, extrude The outlet temperature was 160°C. The polypropylene foam sheet is subjected to 1000mj / cm in the ultraviolet box 2 of ultraviolet radiation. The sheet after ultraviolet irradiation was subjected to a foaming experiment in a foaming furnace, and the foaming temperature was 220°C.

Embodiment 2

[0027] Embodiment two: take by weight 100 parts of polypropylene, 0.2 parts of ultraviolet photoinitiator, 1.6 parts of sensitizer, 10 parts of toughening agent and 0.1 part of antioxidant, mix in high-speed mixer for 10 to 15 minutes , The material temperature is controlled at about 80°C. Then, the homogeneously mixed material is blended, melted and extruded by a twin-screw extruder, and granulated. The extrusion temperature is about 230°C. Take 30 parts of foaming agent masterbatch and mix evenly with the pellets granulated by the twin-screw extruder, carry out non-foaming extrusion on the single-screw extruder, extrude a polypropylene foam sheet with a thickness of 1mm, extrude The outlet temperature was 160°C. The polypropylene foam sheet is subjected to 3000mj / cm in a UV box 2 of ultraviolet radiation. The sheet after ultraviolet irradiation was subjected to a foaming experiment in a foaming furnace, and the foaming temperature was 220°C.

Embodiment 3

[0028] Embodiment three: Weigh 100 parts of polypropylene, 0.2 parts of ultraviolet photoinitiator, 1.6 parts of sensitizer, 10 parts of toughening agent and 0.1 part of antioxidant by mass parts, and mix in a high-speed mixer for 10 to 15 minutes , The material temperature is controlled at about 80°C. Then, the homogeneously mixed material is blended, melted and extruded by a twin-screw extruder, and granulated. The extrusion temperature is about 230°C. Take 30 parts of foaming agent masterbatch and mix evenly with the pellets granulated by the twin-screw extruder, carry out non-foaming extrusion on the single-screw extruder, extrude a polypropylene foam sheet with a thickness of 1mm, extrude The outlet temperature was 160°C. The polypropylene foam sheet is subjected to 5000mj / cm in the ultraviolet box 2 of ultraviolet radiation. The sheet after ultraviolet irradiation was subjected to a foaming experiment in a foaming furnace, and the foaming temperature was 220°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com