A kind of preparation method and application of oxide film material with shape memory effect

A technology of oxide film and memory effect, which is applied in metal material coating process, piezoelectric/electrostrictive device manufacturing/assembly, gaseous chemical plating, etc., can solve unfavorable device applications and improve the working cycle of materials and devices and other issues to achieve the effect of high working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

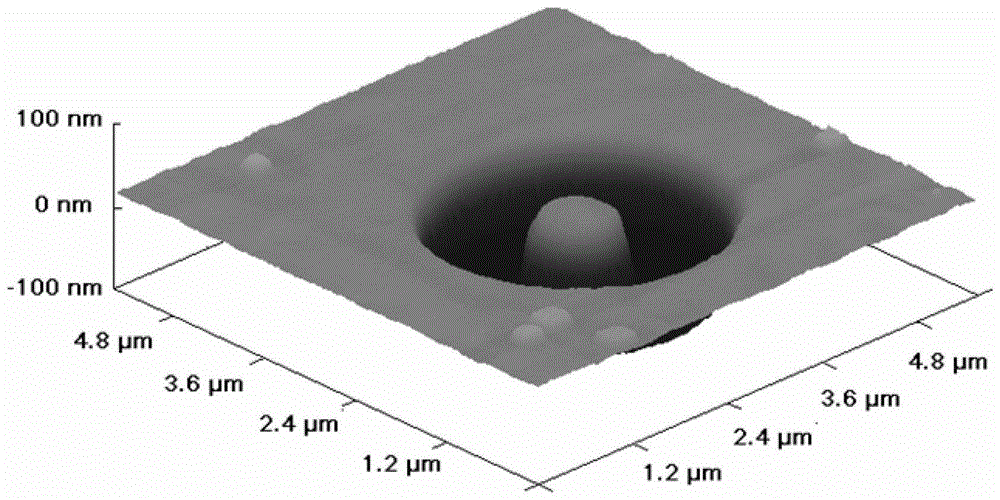

[0029] A preparation method of an oxide thin film material having a shape memory effect, comprising the steps of:

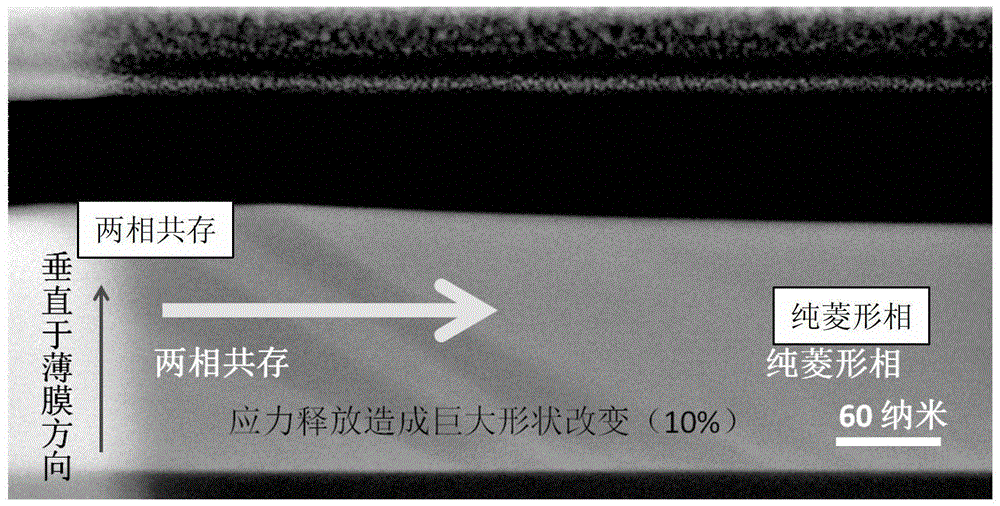

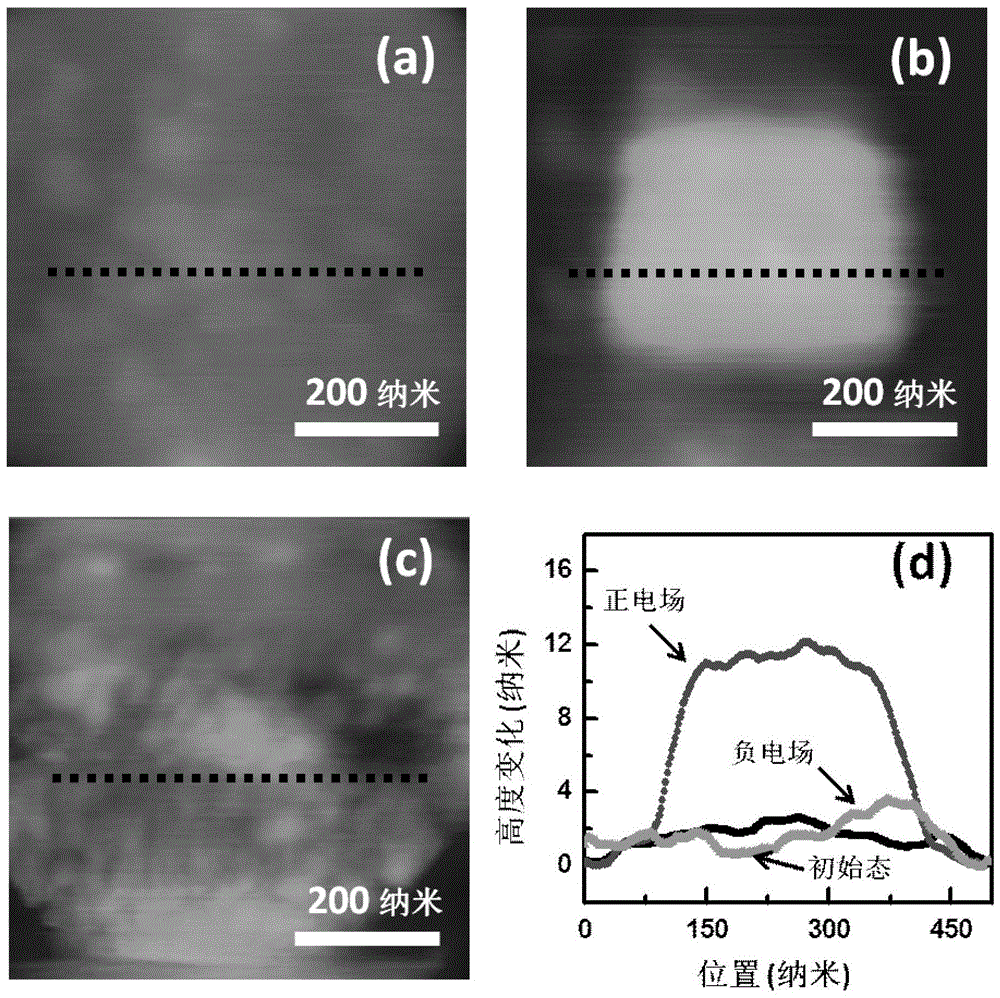

[0030] (1) Using pulsed laser deposition technology, on a high lattice mismatch single crystal substrate LaAlO 3 BiFeO thicker than 150nm was prepared on 3 film. The growth temperature of all films is 700°C, the growth pressure is 13Pa, and the laser energy density is 1.5J / cm 2 , with a growth rate of 2.5 nm / min, forming a mixed phase BiFeO in which rhombohedral and tetragonal phases coexist 3 . In general, mixed-phase BiFeO 3 It is very sensitive to stress, so when the thickness of the film increases to more than 150 nanometers, the basic phase structure is a pure diamond phase. Therefore, in order to successfully epitaxially grow a thicker mixed-phase film, that is, a mixed-phase film with a film thickness greater than 150 nm, we adopted a high oxygen pressure and slow annealing method, that is, under an oxygen pressure state of one atmosphere, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com