Preparation method and application of photoresponsive organogel usable at 80°C

A light-responsive, gel-based technology, which is applied in the preparation of light-responsive organic gels with external cross-linking agents, without adding cross-linking agents, can solve the problems of lack of heat resistance, solvent volatility, etc., and achieve good light-responsive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

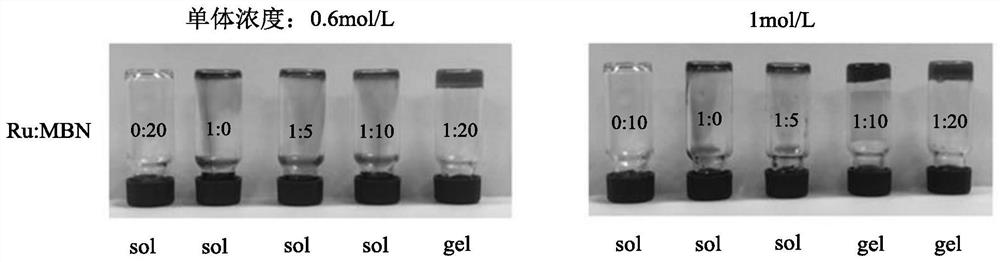

[0043] Aiming at the problems of volatile organic gels and lack of heat resistance in the prior art, this application uses the organic solvent 1,2-propanediol with a high boiling point and low volatility to replace the solvent-water in the traditional hydrogel, and the photoresponsive unit The ruthenium ligand and the benzonitrile-containing ligand were compounded into the gel network, and a light-responsive organic gel usable at 80°C was prepared. Further, the present application can directly form a gel without adding a cross-linking agent by adjusting the monomer concentration and the ratio of the ruthenium-containing complex monomer to the benzonitrile-containing monomer. The reversible transformation of gel-sol can be realized by switching, which can be used for material remodeling. At the same time, based on the color difference of the photoresponsive unit during ligand coordination and dissociation, the gel prepared by adding a cross-linking agent can realize reversible ...

Embodiment 1

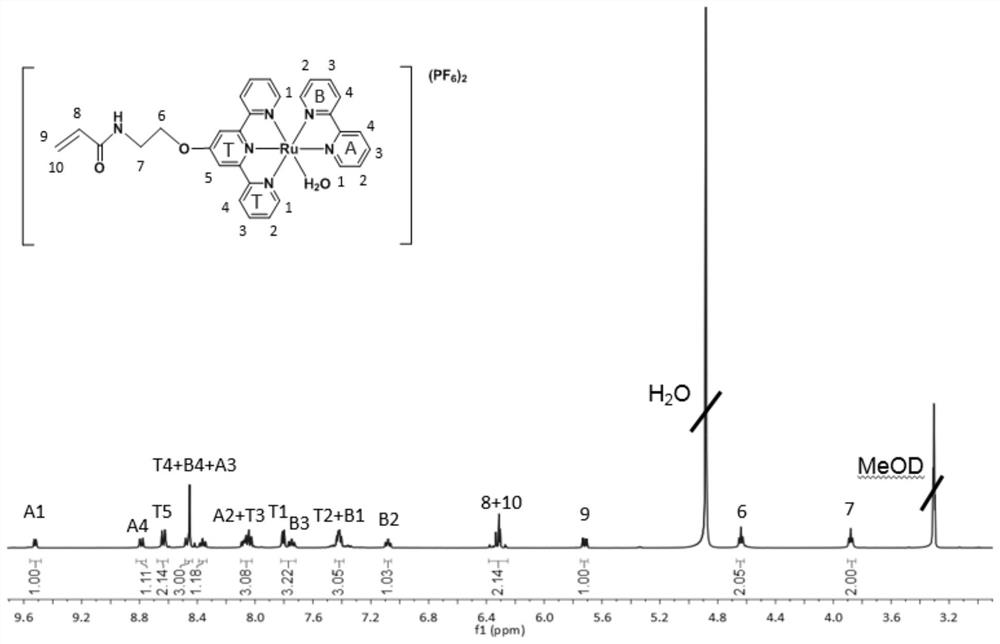

[0077] Embodiment 1 The synthetic method of ruthenium-containing monomer A:

[0078] 1) Add 7mmol potassium hydroxide to 20mL dimethyl sulfoxide, stir and heat to 65°C, slowly add 7.4mmol ethanolamine dropwise to the above solution, stir the system at 65°C for 30min, then add 3.7mmol 4-chloro-2, Add 2,6'',2''-terpyridine to the above system, and stop the reaction after stirring at 65°C for 2 days; the reaction solution is cooled to room temperature, poured into 20ml of deionized water, the crude product is extracted with dichloromethane, anhydrous sulfuric acid Sodium drying, filtration, the reaction solution was filtered and washed with water to obtain a crude product, the oil phase was collected and the solvent was removed by rotary evaporation to obtain a crude product, and a light yellow solid was obtained by recrystallization from ethyl acetate;

[0079] 2) Dissolve 4.7mol of the final product of step 1) in 40mL of anhydrous dichloromethane, add 9.8mol of triethylamine un...

Embodiment 2

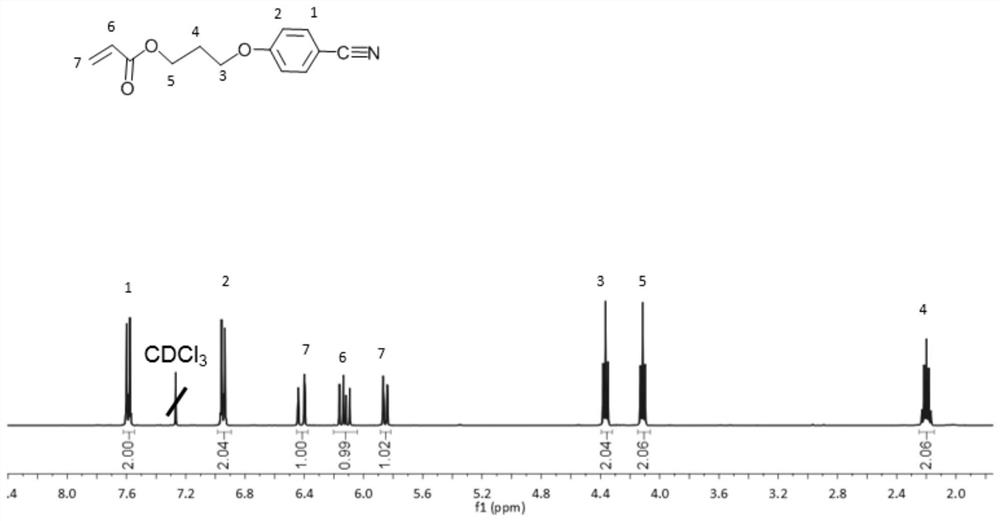

[0083] Embodiment 2 The synthetic method of benzonitrile-containing monomer B:

[0084] 1) Dissolve 10mmol 4-hydroxybenzonitrile, 10mmol potassium carbonate and 0.6mmol potassium iodide in 20ml N,N-dimethylformamide, stir the reaction solution at 110°C for 30min, then add 11mol 3-chloro-1-propane Alcohol was dissolved in 10ml of N,N-dimethylformamide, slowly added dropwise to the above system, stirred and reacted at 110°C for 24 hours, then the reaction was stopped, the reaction mixture was filtered, the residue was washed with dichloromethane, and the solvent was removed by a rotary evaporator to obtain crude Product, the crude product was purified by silica gel column chromatography after drying, and the eluent was petroleum ether and ethyl acetate to obtain a colorless oily liquid;

[0085] 2) Dissolve 5.64mmol of the final product of step 1) and 8.64mmol of triethylamine in 40mL of anhydrous dichloromethane, stir at room temperature for 10min, then slowly add 8.64mmol of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com