Star-shaped polymer with light/heat triple shape memory and preparation method thereof

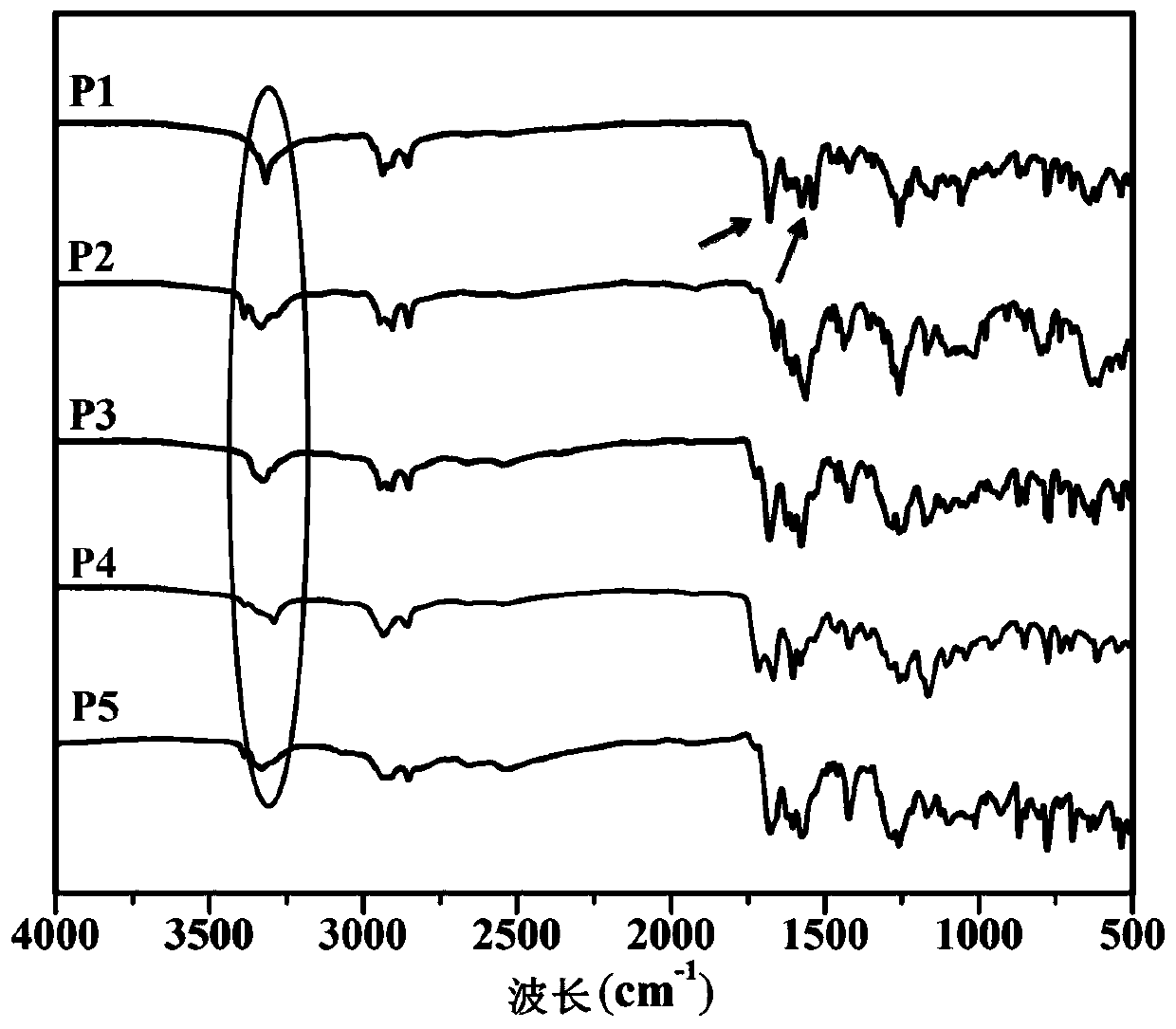

A star-shaped polymer and polymer technology, applied in the field of polymer materials, can solve the problems of poor shape memory performance of shape memory polyurethane, single type of functional group, single function, etc., and achieve good crystal structure, good shape memory performance, and clear support. effect of structuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a light / thermal triple shape memory star polymer, comprising the steps of:

[0031] (1) Weigh 4.8g SPCL (the molecular weight of SPCL is 5800) with an analytical balance, put it into a 250mL three-necked flask, and add an appropriate amount of DMF as a solvent in the flask, then drop two drops of DBTDI as a catalyst, install and stir Rod, the stirring speed is 300-400r / min, put the flask into an oil bath, seal and heat up to 70°C, absorb 0.45mL of HDI with a syringe, slowly drop into the three-necked flask, and react for 1.5h;

[0032] (2) Dissolve 1.15g of Azoba with an appropriate amount of DMF, slowly drop it into a three-necked flask, react for 6min, add 0.716mL of HDI again, and react for 4.2h;

[0033] (3) Add 0.4mL of HDI dropwise to the above liquid, react for another 20-30min, add 0.234g of BDO dropwise, react for 0.9h, and when the reaction is over, pour the liquid in the three-neck flask into the oven while it is hot. Spread the well-h...

Embodiment 2

[0035] A method for preparing a light / thermal triple shape memory star polymer, comprising the steps of:

[0036] (1) Weigh 5.1g SPCL (the molecular weight of SPCL is 5800) with an analytical balance, put it into a 250mL three-necked flask, and add an appropriate amount of DMF into the flask as a solvent, then drop two drops of DBTDI as a catalyst, install and stir Rod, the stirring speed is 300-400r / min, put the flask into an oil bath, seal and heat up to 80°C, absorb 0.5mL of HDI with a syringe, slowly drop into the three-necked flask, and react for 1.6h;

[0037] (2) Dissolve 0.92g of Azoba with an appropriate amount of DMF, slowly drop it into a three-necked flask, react for 4min, add 0.572mL of HDI again, and react for 3.8h;

[0038] (3) Add 0.5mL of HDI dropwise to the above liquid, react for another 20-30min, add 0.234g of BDO dropwise, react for 1.1h, and the reaction is over. Spread the well-heated petri dish into a moderately thick film, and place the petri dish in ...

Embodiment 3

[0040] A method for preparing a light / thermal triple shape memory star polymer, comprising the steps of:

[0041](1) Weigh 5g SPCL with an analytical balance (the molecular weight of SPCL is 5800), put it into a 250mL three-necked flask, and add an appropriate amount of DMF as a solvent in the flask, then drop two drops of DBTDI as a catalyst, and install a stirring bar , the stirring speed is 300-400r / min, put the flask into an oil bath, seal and heat up to 75°C, absorb 0.45mL of HDI with a syringe, slowly drop it into a three-necked flask, and react for 1.5h;

[0042] (2) Dissolve 0.767g of Azoba with an appropriate amount of DMF, slowly drop it into a three-necked flask, react for 5min, add 0.477mL of HDI again, and react for 4h;

[0043] (3) Add 0.45mL of HDI dropwise to the above liquid, react for another 20-30min, add 0.234g of BDO dropwise, react for 1h, and when the reaction is over, pour the liquid in the three-necked flask into the oven while it is hot and preheat it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com