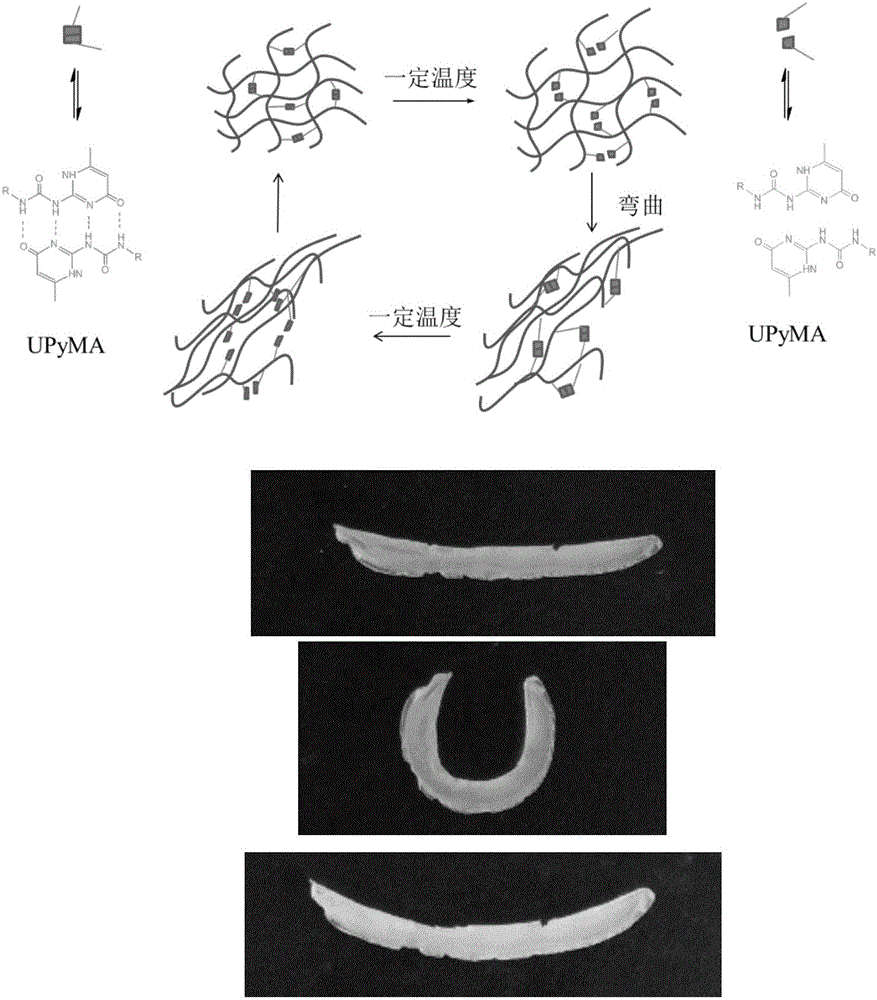

Thermal response shape memory hydrogel based on hydrogen-bond interaction and preparation method of thermal response shape memory hydrogel

A technology of hydrogen bonding and hydrogel, applied in the field of heat-responsive shape memory hydrogel and its preparation, can solve the problems of limited application and weak mechanical properties, and achieve low raw material cost, good shape memory performance, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A heat-responsive shape memory hydrogel based on hydrogen bonding, which includes the following weights of raw materials: N,N'-dimethylacrylamide (DMA) 1.7g, N,N'-methylenebisacrylamide ( MBA) 0.05g, 2-urea-4[1H]-methylpyrimidone methacrylate (UPyMA) 1.6g, ammonium persulfate 0.03g, dimethylsulfoxide (DMASO) 10mL.

[0018] Above-mentioned each raw material is prepared according to the following steps:

[0019] 1) N,N'-dimethylacrylamide (DMA), N,N'-methylenebisacrylamide (MBA), 2-urea-4[1H]-methylpyrimidinone methacrylate ( UPyMA), ammonium persulfate, and dimethyl sulfoxide (DMASO) are put into the container in proportion, preheated at 40-50°C to dissolve and mix the raw materials evenly, then heat up to 65-80°C, and react for 3 hours;

[0020] 2) Soak the prepared DMSO gel in deionized water for a certain period of time at room temperature, so that the DMSO is completely replaced by water;

[0021] 3) Continue to swell the hydrogel obtained in step 2 in deionized wa...

Embodiment 2

[0025] The shape-memory hydrogel of this embodiment includes the following raw materials by weight: 2.1 g of N,N'-dimethylacrylamide (DMA), 0.06 g of N,N'-methylenebisacrylamide (MBA), 2 - 1.3 g of urea-4[1H]-methylpyrimidinone methacrylate (UPyMA), 0.05 g of ammonium persulfate, and 10 mL of dimethyl sulfoxide (DMASO).

[0026] The preparation method of the hydrogen bond-based shape memory hydrogel in this example is the same as that in Example 1.

[0027] The hydrogen bond-based shape memory hydrogel of this example has substantially the same mechanical properties and shape memory properties as those of Example 1.

Embodiment 3

[0029] The shape-memory hydrogel of this embodiment includes the following raw materials by weight: 2.8 g of N,N'-dimethylacrylamide (DMA), 0.06 g of N,N'-methylenebisacrylamide (MBA), 2 - 1.2 g of urea-4[1H]-methylpyrimidinone methacrylate (UPyMA), 0.04 g of ammonium persulfate, and 10 mL of dimethyl sulfoxide (DMSO).

[0030] The preparation method of the hydrogen bond-based shape memory hydrogel of this embodiment is the same as that of the first embodiment.

[0031] The shape-memory hydrogel based on hydrogen bonds in this example has substantially the same mechanical properties and shape-memory properties as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com