Synergistic removal system and method for realizing ultra-low emission of multiple pollutants of smoke of thermal power plant

A technology for pollutants and thermal power plants, applied in combustion methods, combustion using block fuels and gaseous fuels, combustion using liquid fuels and gaseous fuels, etc., can solve the problems of reduced boiler combustion efficiency, high ammonia escape, and urea consumption Large and other problems, to achieve the effect of improving dust removal efficiency, ultra-low emissions, and reducing specific resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

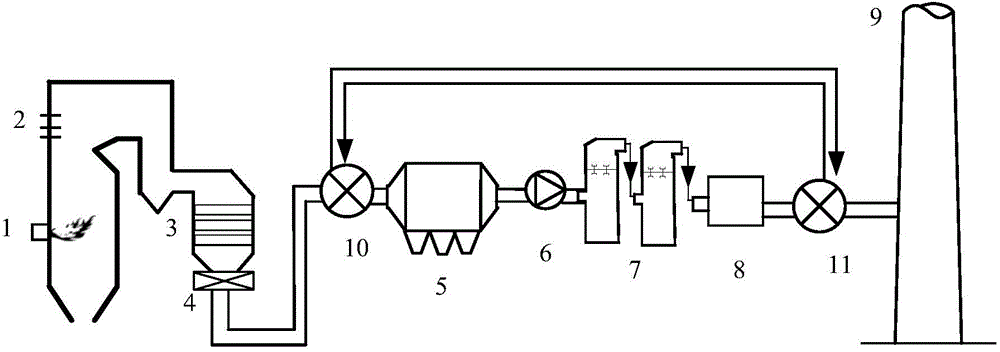

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] On the premise of meeting the ultra-low emission requirements, the present invention needs to optimize the overall environment protection facilities in order to minimize the impact of the operation of the environment protection facilities on the thermal efficiency of the boiler, the plant power consumption rate and the unit efficiency. At the same time, the invention is applicable to new coal-fired units and old coal-fired units, and can regard the environmental protection facilities of the power plant as an organic whole, and has the advantages of reliable technical route, advanced environmental protection indicators, low overall investment level, and significant energy saving and consumption reduction. For old coal-fired units, it is necessary to transform them based on existing environmental protection facilities to save costs. For new coal-fired un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com