Biomass liquefying method adopting fluidized pyrolysis and matched device thereof

A biomass and biomass powder technology, which is applied in the fields of biofuel, educt, direct heating and dry distillation, etc., can solve the problems of secondary environmental pollution, high liquefaction cost, unfavorable industrialization, etc., and achieves less equipment investment and shorter residence time. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

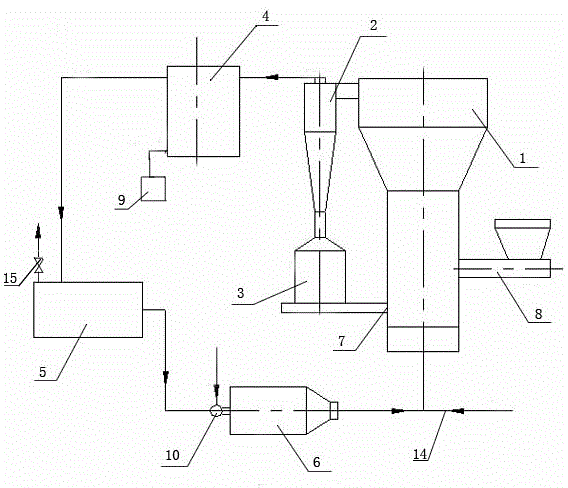

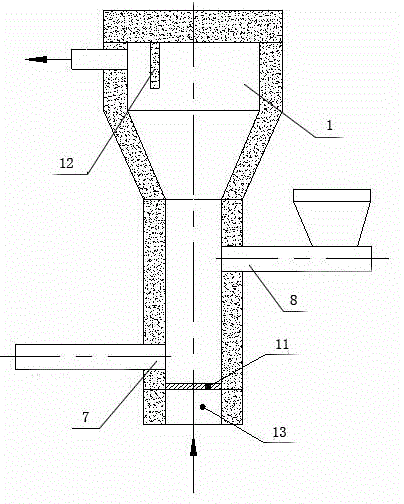

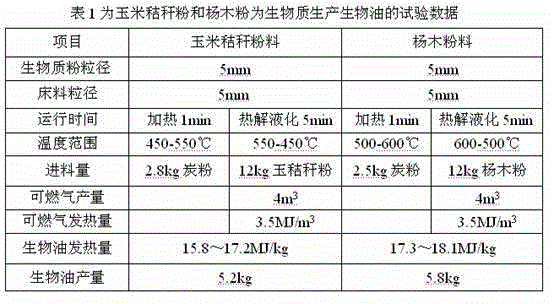

[0023] Biomass fluidized pyrolysis liquefaction methods, such as figure 1 shown, including the following steps:

[0024] (1) Feed the biomass powder into the fluidized bed pyrolysis furnace 1, use air as the fluidized medium to fully burn the biomass, and raise the temperature of the fluidized bed pyrolysis furnace 1 to 600-650°C;

[0025] (2) Increase the feeding amount of biomass powder so that the incomplete combustion of biomass in the fluidized bed pyrolysis furnace 1 collects carbon powder, bio-oil and combustible gas, and the combustible gas is stored in the gas storage tank 5 to maintain heat The temperature in the furnace remains unchanged;

[0026] (3) After the combustible gas in the gas storage tank 5 is full, start the combustible gas burner 10, use the generated high-temperature flue gas as the fluidizing medium, and stop the air supply at the same time; feed biomass powder to pyrolyze the fluidized bed The furnace operates under flash pyrolysis conditions;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com