Environmentally-friendly energy-saving carbon reduction type TPU (thermoplastic polyurethane elastomer rubber) forming method and device

An environment-friendly, energy-saving, molding device technology, applied in coating and other directions, can solve the problems of inconvenient material preparation for users, inability to meet environmental protection, energy saving, carbon reduction requirements, and increase production costs, and achieve the effect of omitting energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

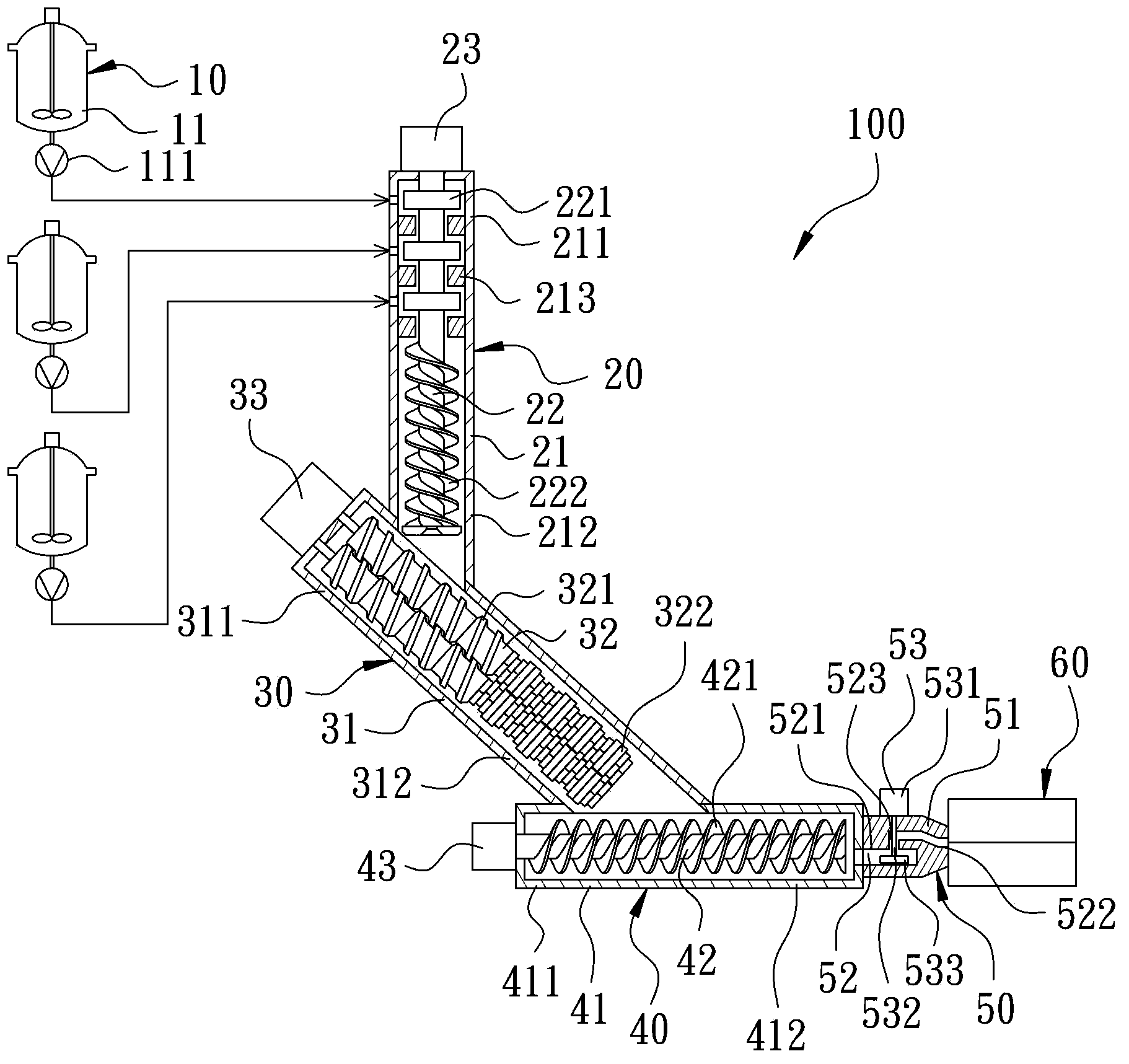

[0044] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention, which are only provided for reference and description, and are not intended to limit the present invention.

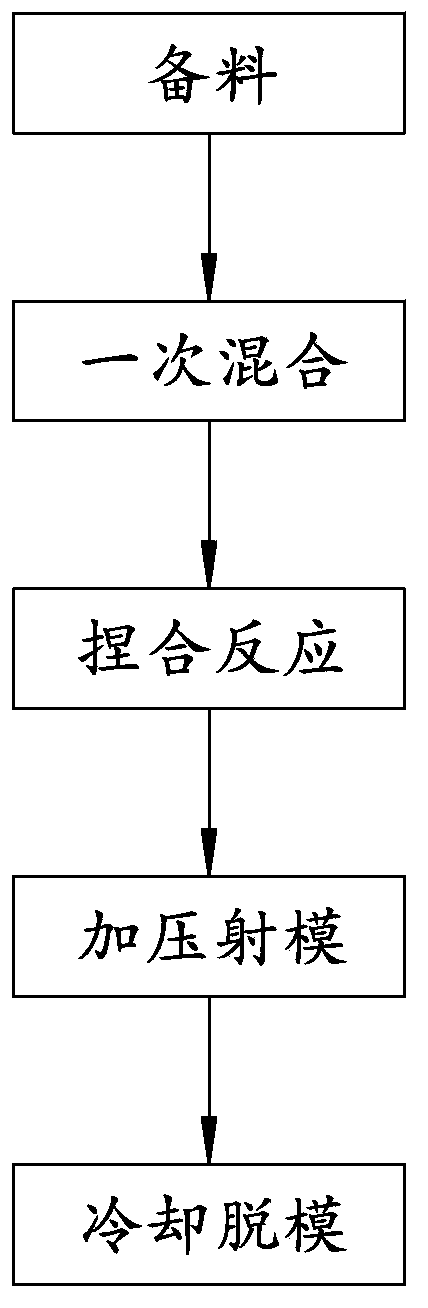

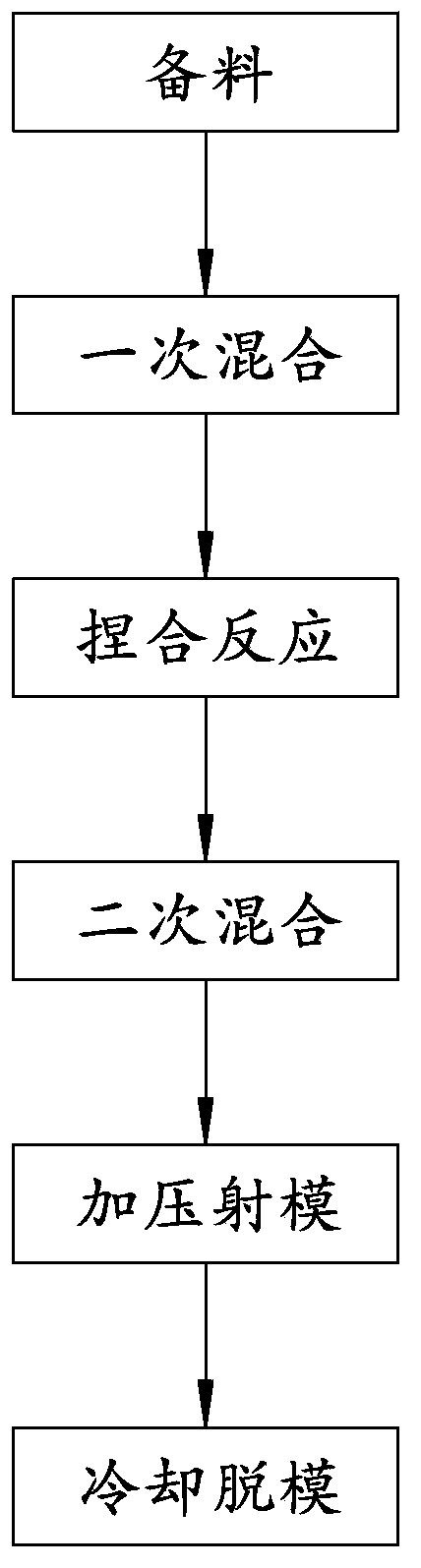

[0045] see figure 1 As shown, it is a flow chart of the steps of the first preferred embodiment of the present invention, which discloses a molding method of an environmentally friendly, energy-saving and carbon-reducing TPU (thermoplastic polyurethane elastomer rubber), and the molding method of the environmentally-friendly, energy-saving and carbon-reducing TPU includes Follow these steps:

[0046] Material preparation step: prepare an isocyanate polymer containing NCO (isocyanate group), a hydroxyl compound containing OH (hydroxyl group) and a chain extender.

[0047] A mixing step: mixing the isocyanate polymer containing NCO (isocyanate group), the hydroxyl compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com