Industrial production method of lactulose

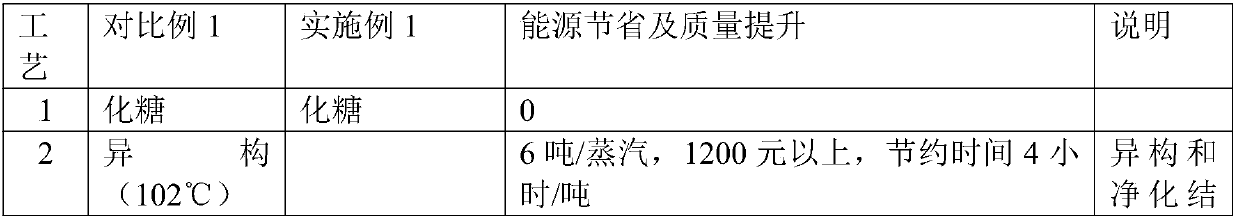

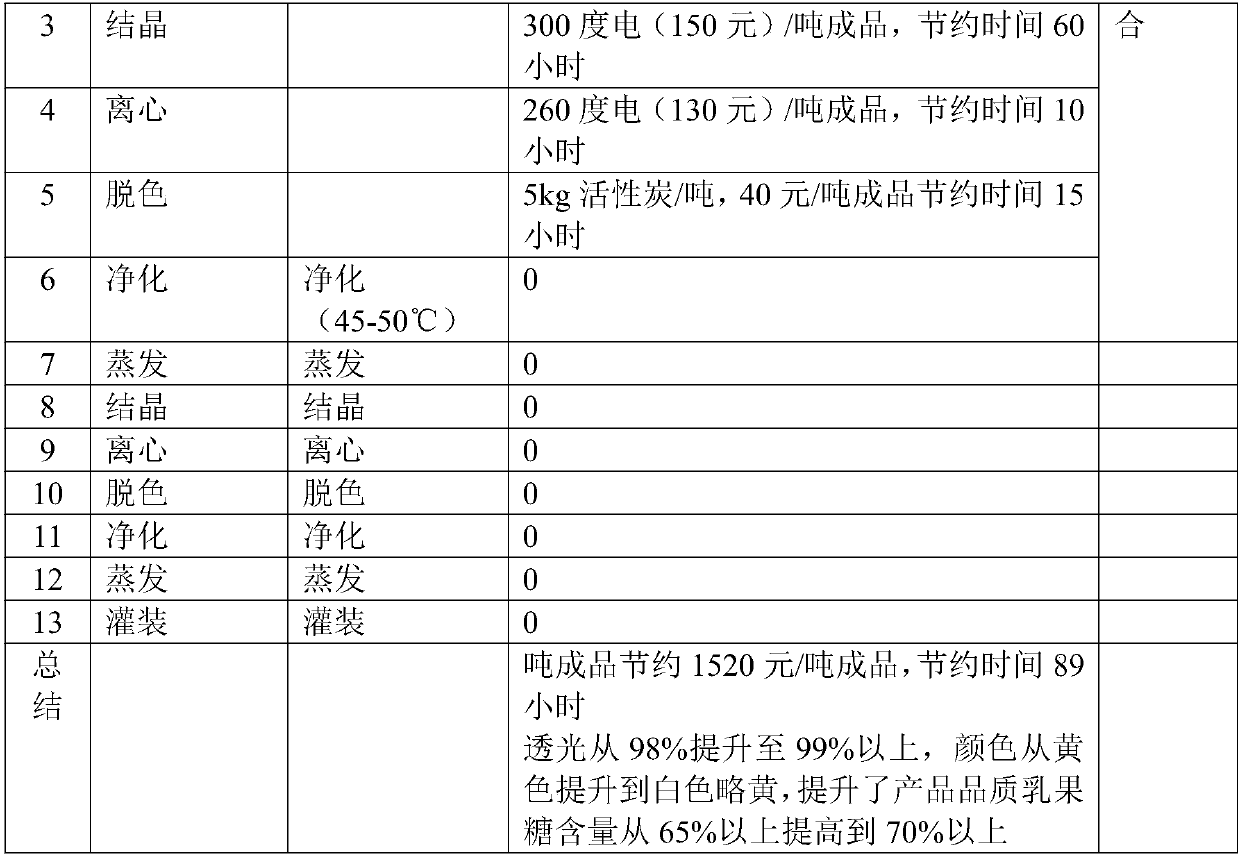

A production method, lactulose technology, applied in the field of preparation of functional sugar alcohols, can solve the problems of low yield and purity of lactulose, complex post-treatment process, long preparation process, etc., achieve process optimization, broad industrial application prospects, save The effect of process and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Lactose sugar 15 cubic meters, refraction 67%, pH 6, temperature 48°C, flow rate 5.5 cubic meters / hour, feed conductivity 1895 μs / cm, light transmission 38.5%, feed lactose content 99.5%, lactulose 0.

[0052] Yin bed (D301) discharge, refraction 66.1%, flow rate 5.5 m3 / hour, discharge conductance 187μs / cm, discharge light transmission 97.2%, discharge content: lactulose 12.35%, galactose 1.34%, lactose content 85.6% ,

[0053] Yang bed (D001) output, refraction 65.3%, flow rate 5.5 m3 / hour, output conductance 8.4μs / cm, output light transmission 98.9%, output content: lactulose 12.38%, galactose 1.33%, lactose content 85.55 %.

[0054] The refraction of the evaporation output is 75.6%, the temperature is 80°C,

[0055] Cooling crystallization rate: 1°C / hour, centrifugation temperature 40°C;

[0056] Centrifugal speed: 500-1000 r / min, mother liquor refraction 40-55% after centrifugation, content: lactulose: 71.5%, galactose 8.96%, lactose 13.77%;

[0057] Decolorizat...

Embodiment 2

[0062] 20 cubic meters of lactose, refraction 68%, temperature 45°C, pH 5.5, flow rate 5.5 cubic meters / hour, feed conductivity 1898μs / cm, light transmission 38.1%, feed lactose content 99.6%, lactulose 0.

[0063] Yin bed (D301) output, refraction 65.4%, flow rate 5.7 m3 / hour, output conductance 168μs / cm, output light transmission 97.3%, output content: lactulose 12.49%, galactose 1.39%, lactose content 85.31% ,

[0064] Yang bed (D001) output, refraction 65.3%, flow rate 5.7 m3 / hour, output conductance 7.6μs / cm, output light transmission 98.8%, output content: lactulose 12.45%, galactose 1.31%, lactose content 85.62 %.

[0065] The refraction of the evaporation output is 75.9%, and the temperature is 80°C;

[0066] Cooling crystallization rate: 1°C / hour, centrifugation temperature 40°C;

[0067] Centrifugal speed: 500-1000 r / min, mother liquor refraction 40-55% after centrifugation, content: lactulose: 71.7%, galactose 8.81%, lactose 13.33%;

[0068] Decolorization proce...

Embodiment 3

[0074] Lactosylated sugar 15 m³, refraction 68.2%, temperature 47.6°C, pH 6.5, flow rate 5.5 m³ / hour, feed conductivity 1735 μs / cm, light transmission 38.9%, feed lactose content 99.47%, lactulose 0.

[0075] Yin bed (D301) output, refraction 65.89%, flow rate 5.5 m3 / hour, output conductance 168μs / cm, output light transmission 97.45%, output content: lactulose 12.49%, galactose 1.41%, lactose content 85.44% ,

[0076] Yang bed (D001) output, refraction 65.34%, flow rate 5.5 m3 / hour, output conductance 7.6μs / cm, output light transmission 98.88%, output content: lactulose 12.48%, galactose 1.3%, lactose content 85.59 %.

[0077] The refraction of the evaporation output is 75.8%, the temperature is 80°C,

[0078] Cooling crystallization rate: 1°C / hour, centrifuge temperature 41°C

[0079] Centrifugal speed: 500-1000 rev / min, mother liquor refraction 40-55% after centrifugation, content: lactulose: 71.82%, galactose 8.76%, lactose 13.27%

[0080] Decolorization process: the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com