Pipeline filtration mixing device

A mixing device and pipeline technology, which is applied in the field of pipeline filtration and mixing devices, can solve problems such as long time-consuming, cumbersome procedures, and unfavorable production efficiency, and achieve the effect of saving procedures and time and improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

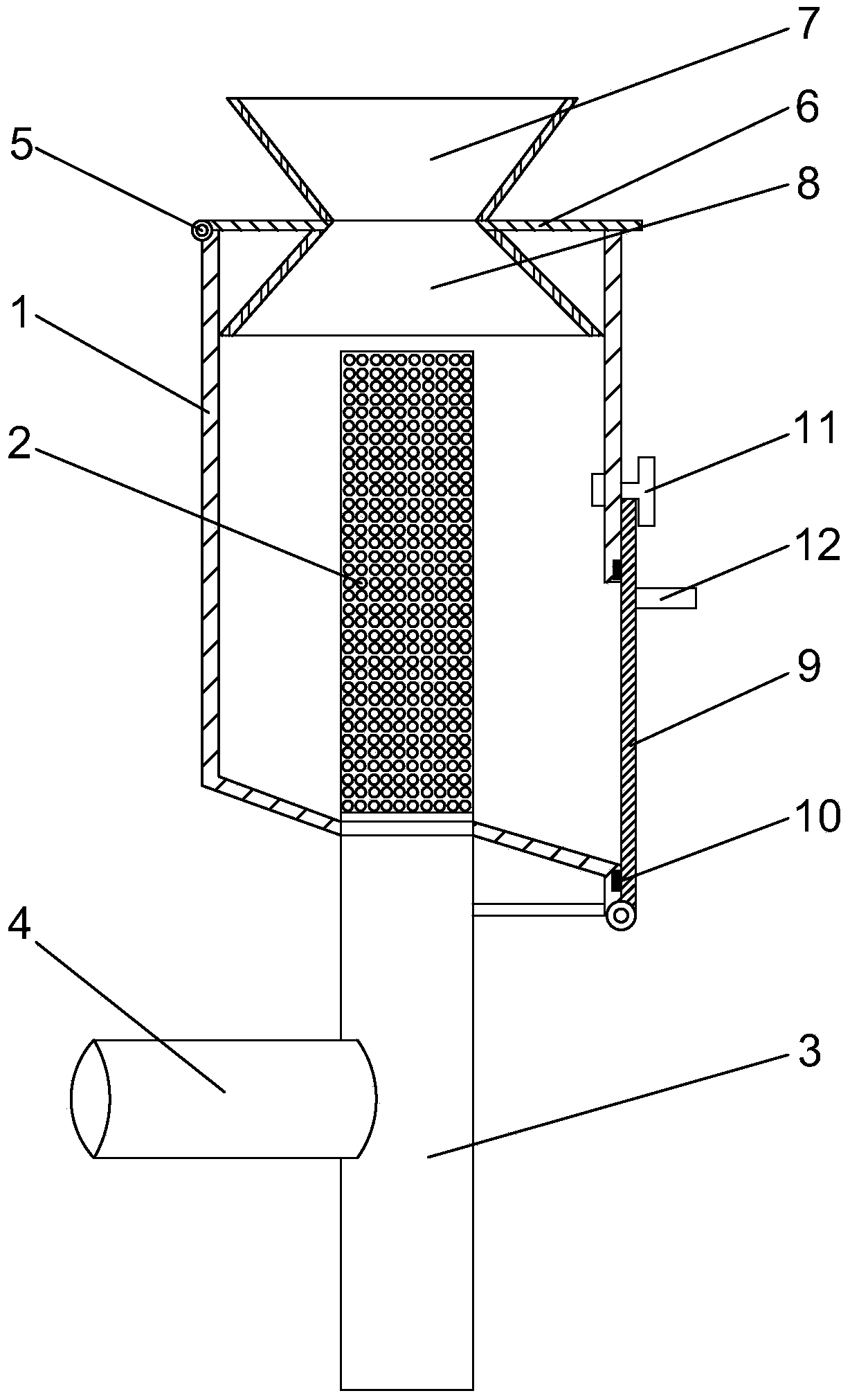

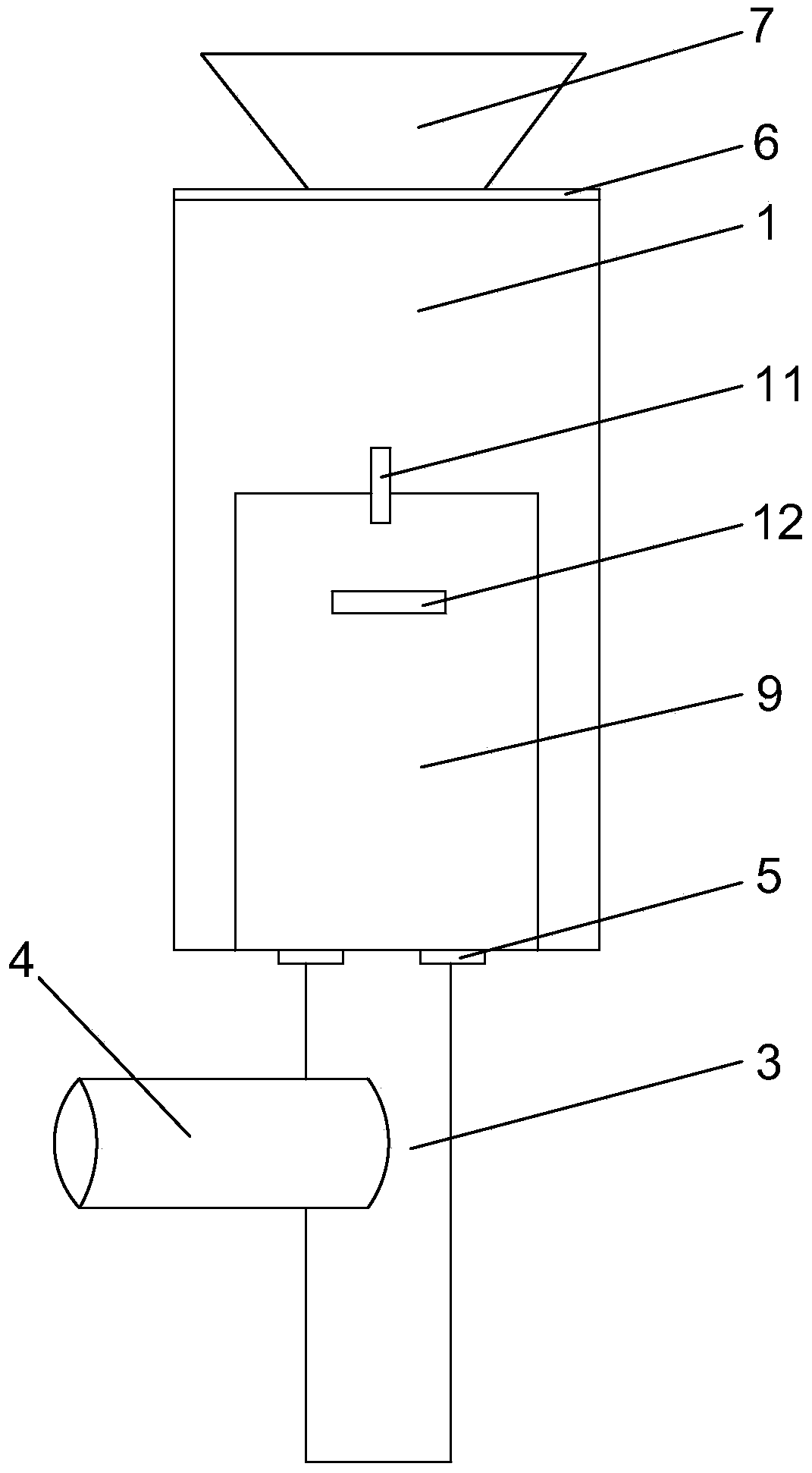

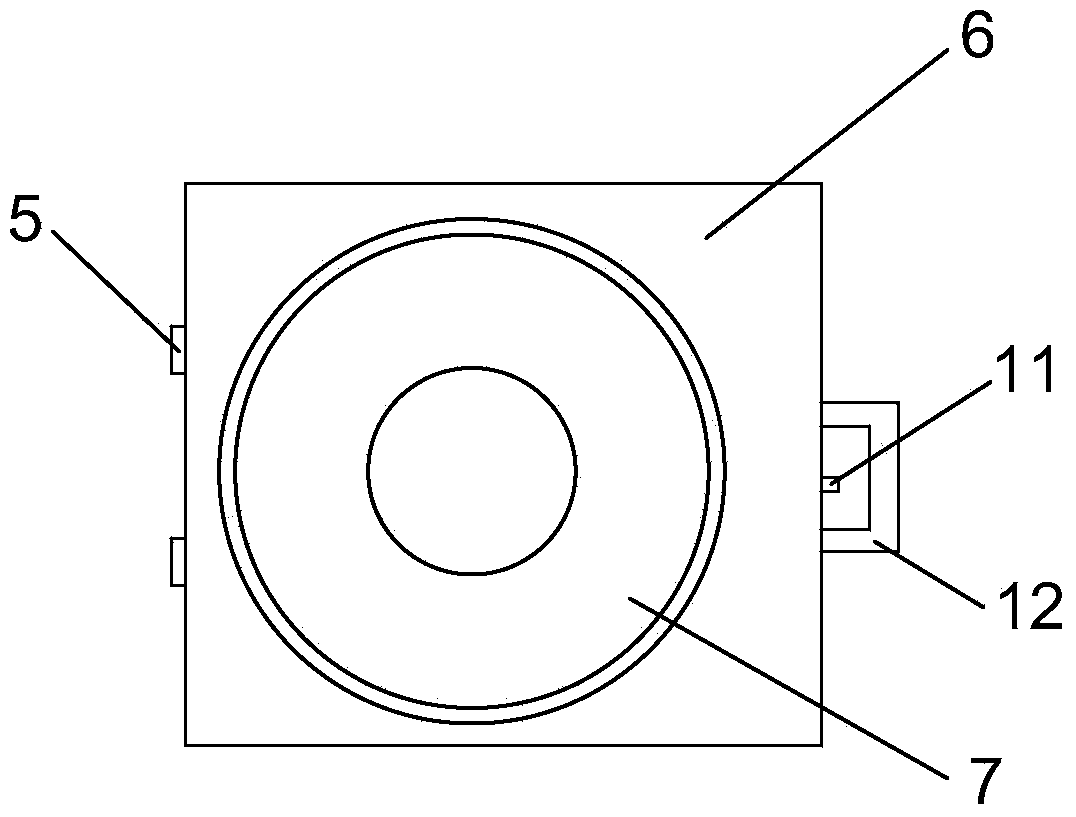

[0011] Such as figure 1 , 2 , 3, a pipeline filter mixing device of the present invention comprises a casing 1, a filter pipe network 2, and a discharge pipe 3, the bottom of the casing 1 is connected with a discharge pipe 3 communicating with the casing 1, and at the outlet The feed pipe 3 is provided with a water inlet pipe 4 communicating with the discharge pipe 3, and the top 1 of the box body is provided with an upper cover 6 through the rotating shaft 5, and the upper and lower sides of the upper cover 6 are respectively provided with an upper funnel 7 with a relatively thinner mouth and The lower funnel 8 is connected with a filter pipe network 2 through threads at the discharge nozzle inside the box body 1, and a sealing door 9 is installed on one side of the box body 1 through a rotating shaft 5, between the sealing door 9 on the edge of the sealing door and the box body 1 A ring sealing ring 10 is arranged between, a T-shaped valve 11 for fixing the sealing door 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com