Nutgall acylation modified fibre an dits synthetic method

A technology of gallocylation modification and synthesis method, which is applied in the field of gallocylation modified cellulose and its synthesis, can solve the problems of unfavorable stability, large steric hindrance, etc., and achieve the effect of low cost and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

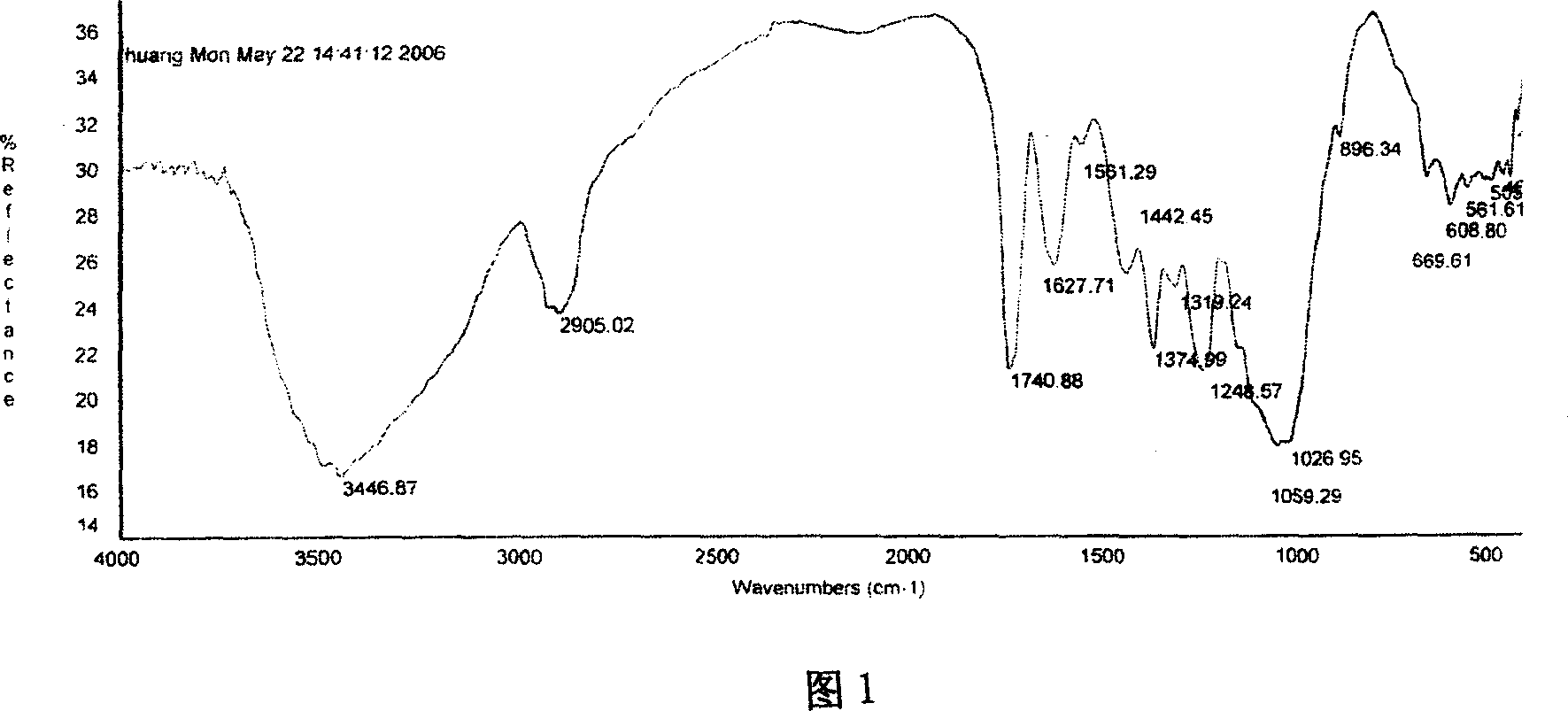

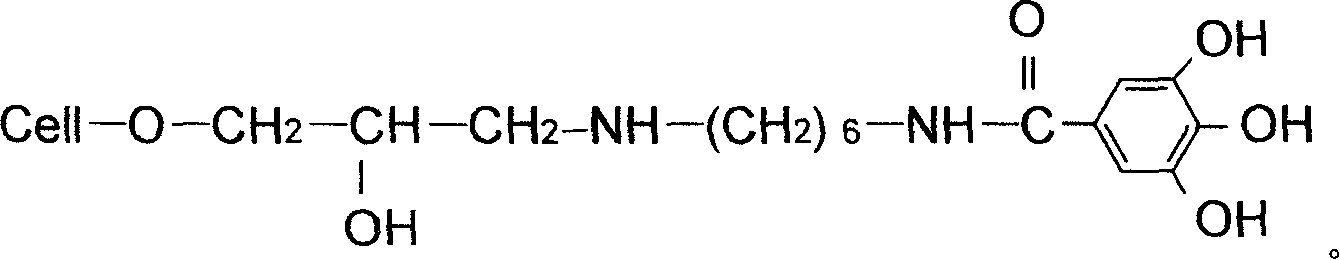

[0041] Example 1 A gallocylated modified cellulose capable of adsorbing and binding proteins and complexing metal ions,

[0042] The structural formula is:

[0043] Wherein, Cell-OH represents cellulose, which may be wood pulp cellulose in this embodiment, and the mass fraction of α-cellulose in the wood pulp cellulose is greater than 80%, and the degree of polymerization is 700-1000.

Embodiment 2

[0044] Embodiment 2 A kind of synthetic method of galloacylated modified cellulose, comprises the following steps:

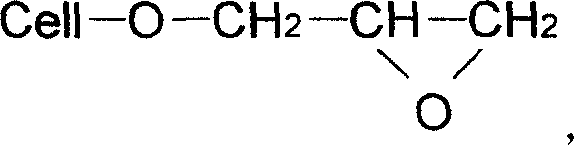

[0045] Step 1, disperse the pretreated cellulose powder in a sodium hydroxide solution with a mass concentration of 4% to 8%, add epichlorohydrin and emulsifier Span 80, and stir and react at a temperature of 20 to 60°C 2 ~6h, the ratio of materials is: cellulose powder: epichlorohydrin: sodium hydroxide solution: Span 80 = 1: (5 ~ 8): (35 ~ 45): (0.05 ~ 0.1), wherein the cellulose powder Hespan 80 is measured in mass unit g, and epichlorohydrin and sodium hydroxide aqueous solution are measured in volume unit mL. After the reaction is completed, vacuum filtration is performed to elute epichlorohydrin and its viscous homopolymer to obtain Glycidyl cellulose with about 75% water:

[0046]

[0047] Step 2, stirring and reacting the above-mentioned glycidyl cellulose and hexamethylenediamine aqueous solution with a mass concentration of 1 to 2% at a temperature...

Embodiment 3

[0054] Embodiment 3 A method for synthesizing gallocylated modified cellulose, comprising the following steps:

[0055] Step 1: First, the wood pulp cellulose is crushed into powder, sieved through a 1-2mm sieve plate, purified with alkali, then acidified with acetic acid to remove alkali, washed with water, and dried to obtain cellulose powder, which is then Dispersed in sodium hydroxide solution with a mass concentration of 4% to 8%, the mass concentration of sodium hydroxide solution can be selected as 4.5%, 5%, 5.2%, 5.8%, 6%, 7%, 7.5%, 7.7% , add epichlorohydrin and emulsifier Span 80 (code name: Span 80, i.e. oleic acid herbal tea alcohol), the ratio of materials (ratio with dimension) is: cellulose powder: epichlorohydrin: sodium hydroxide Solution: Span 80 = 1: (5-8): (35-45): (0.05-0.1), for example, 1:5:36:0.05, 1:5:37:0.05, 1:5 :38.5:0.05, 1:5:39.5:0.05, 1:5:40:0.05, 1:5:42:0.05, 1:5:44:0.05, 1:5:43.5:0.05, 1:6:39.5 :0.05, 1:7:39.5:0.05, 1:7.5:39.5:0.05, 1:5:39.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com