A method for producing nano-zinc phosphate by negative pressure ultrasonic method and nano-zinc phosphate

An ultrasonic method, zinc phosphate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor zinc phosphate activity and hydrolysis, complicated doping treatment work, and unsatisfactory effect, and achieves omission of energy. Consumption, shortened reaction time, excellent effect of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

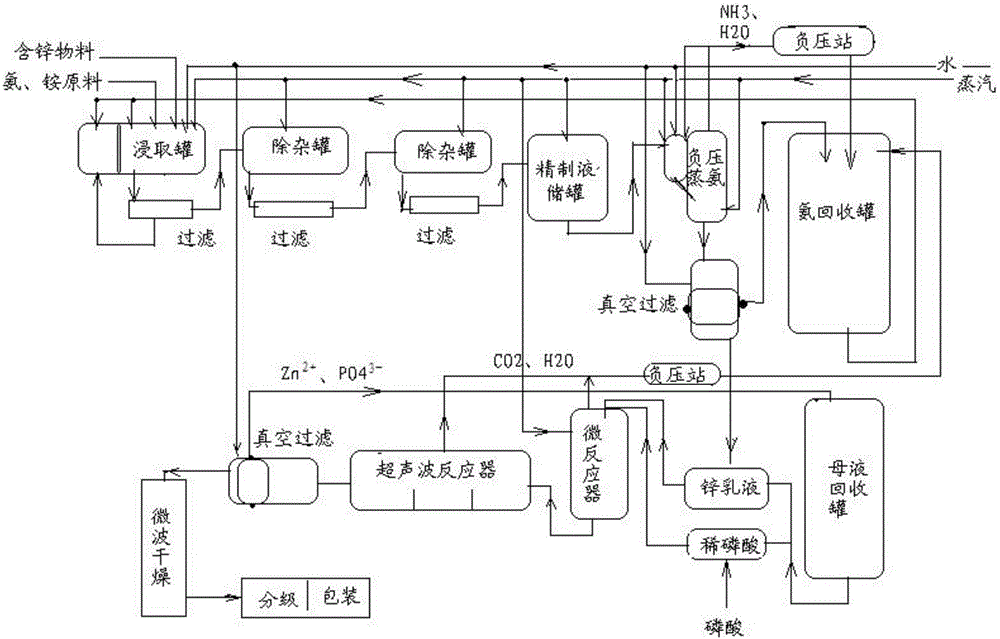

[0049] A kind of negative pressure ultrasonic method of the present invention produces the method for nano-zinc phosphate, and its process flow chart is as figure 1 shown, including the following steps:

[0050] 1. Preparation of basic zinc carbonate:

[0051] 1) For the first time, add 4mol / L ammonium bicarbonate and 4.5mol / L concentrated ammonia water to prepare 9 cubic meters of pre-soaking liquid: add 3 cubic meters of water to the batching tank, and add 2850 kg (9*4.0*79) of ammonium bicarbonate and 3440 kilograms (9*4.5*17 / 20%) concentration is 20% concentrated ammonia water, be warmed up to 25~30 ℃, add water and dilute to 9 cubic meters, after sampling and confirming that ammonium bicarbonate is all dissolved, measure (determined value is to be used to recover ammonia water in the future , ammonium bicarbonate, and concentrated ammonia water to prepare the pre-immersion solution) the specific gravity (fixed temperature, such as 25° C.) and pH value of the ammonia-ammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com