Multi-pass thickening molding integrated heavy weight drill pipe manufacturing method

A manufacturing method and multi-pass technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of large amount of raw materials, low pass rate, high cost, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

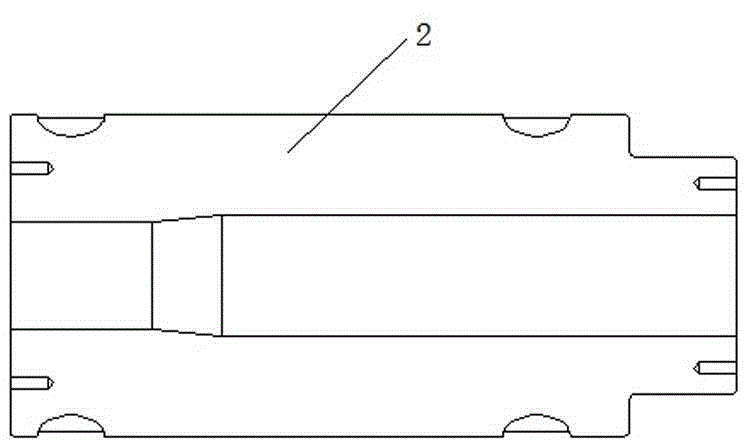

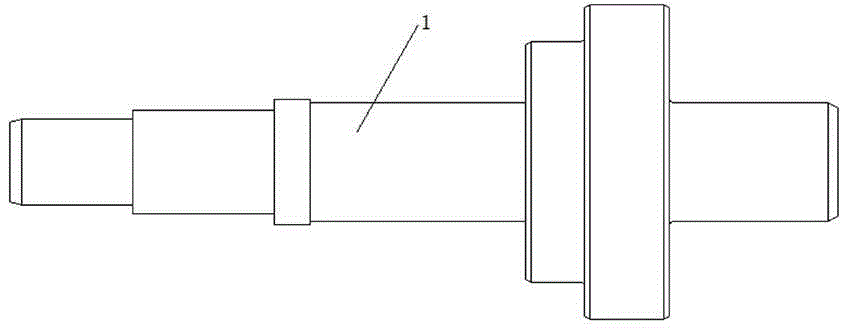

[0016] Embodiment one: if figure 1 , figure 2 As shown, the manufacturing method of multi-pass thickening and forming integrally weighted drill pipe, the specific steps are as follows:

[0017] (1) Use large-wall thick seamless steel pipes containing high molybdenum and high chromium alloys as raw materials; this is convenient to ensure the hardenability of the material;

[0018] (2) Using an intermediate frequency furnace to conduct intermediate frequency heating on the end of the seamless steel pipe, the heating temperature is 1190°C; this is convenient for the subsequent upsetting process;

[0019] (3), first put the forming mandrel 1 into the interior of the seamless steel pipe, and clamp it on the outside of the seamless steel pipe with the thickening die 2, and then push the above seamless steel pipe into the extrusion die, Start the upsetting extrusion machine to forge the seamless steel pipe as a whole to a finished product that conforms to the shape of the above-me...

Embodiment 2

[0022] Embodiment two: if figure 1 , figure 2 As shown, the manufacturing method of multi-pass thickening and forming integrally weighted drill pipe, the specific steps are as follows:

[0023] (1) Use large-wall thick seamless steel pipes containing high molybdenum and high chromium alloys as raw materials;

[0024] (2) Using an intermediate frequency furnace to conduct intermediate frequency heating on the end of the seamless steel pipe, and the heating temperature is 1205°C;

[0025] (3), first put the forming mandrel 1 into the interior of the seamless steel pipe, and clamp it on the outside of the seamless steel pipe with the thickening die 2, and then push the above seamless steel pipe into the extrusion die, Start the upsetting extruder to forge the seamless steel pipe as a whole to a finished product conforming to the shape of the above-mentioned thickening die 2, wherein the clamping force of the upsetting extruder is 5.6MN, the upsetting pressure is 425MPa, and th...

Embodiment 3

[0028] Embodiment three: as figure 1 , figure 2 As shown, the manufacturing method of multi-pass thickening and forming integrally weighted drill pipe, the specific steps are as follows:

[0029] (1) Use large-wall thick seamless steel pipes containing high molybdenum and high chromium alloys as raw materials;

[0030] (2) Using an intermediate frequency furnace to conduct intermediate frequency heating on the end of the seamless steel pipe, and the heating temperature is 1210°C;

[0031] (3), first put the forming mandrel 1 into the interior of the seamless steel pipe, and clamp it on the outside of the seamless steel pipe with the thickening die 2, and then push the above seamless steel pipe into the extrusion die, Start the upsetting extrusion machine to forge the seamless steel pipe as a whole to a finished product conforming to the shape of the thickening die 2 above, wherein the clamping force of the upsetting extrusion machine is 7.8MN, the upsetting pressure is 425M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com