Deformable composite insulation board and production method thereof

A technology of composite thermal insulation and thermal insulation board, which is applied in the direction of thermal insulation, pipeline protection, and pipeline protection through heat insulation, etc. It can solve the problems that the closed cell rate cannot reach 100%, the thermal conductivity is not low enough, and the difficulty in making molds, etc., to achieve improvement Thermal insulation effect, convenient construction, thermal insulation performance to avoid the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

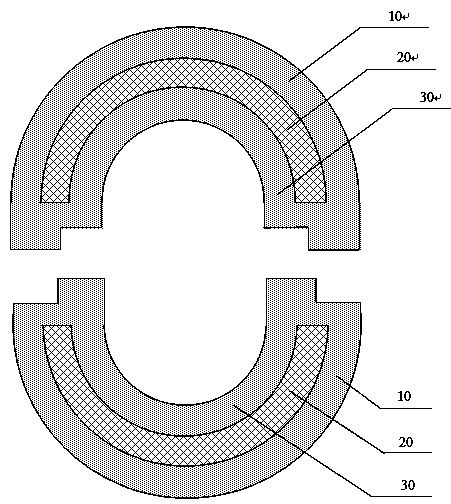

[0027] Brush a layer of release agent evenly on the inner wall of the mold; pre-bond a 7mm thick silicone rubber block on the inner and outer surfaces of the 7mm thick vacuum insulation core material and place it accurately in the center of the mold; put the AB component of the polycondensation silicone rubber Stir and mix evenly with a ratio of 20:1 to prepare pink liquid silicone rubber; slowly pour the evenly mixed liquid silicone rubber into the mold, close the mold and compact it, and after curing at room temperature for 24 hours, remove the mold and remove the board, trim the corners Obtain a 21mm thick pink deformable composite insulation board.

Embodiment 2

[0029] Brush a layer of release agent evenly on the inner wall of the mold; pre-bond a 5mm thick silicone rubber block on the inner and outer surfaces of the vacuum insulation panel wrapped with 8mm thick aluminum foil and place it accurately in the center of the mold; put the AB of polycondensation silicone rubber The components are uniformly stirred and mixed at a ratio of 30:1 to prepare blue liquid silicone rubber; slowly pour the uniformly mixed liquid silicone rubber into the mold, close the mold and compact it, and after curing at room temperature for 18 hours, remove the mold and take the plate. Trim the corners to get 18mm thick blue deformable composite insulation board.

Embodiment 3

[0031] Apply a layer of release agent evenly on the inner wall of the mold; pre-bond a 3mm thick silicone rubber block on the inner and outer surfaces of the 8mm thick vacuum insulation panel and place it accurately in the center of the mold; put the AB component of the addition silicone rubber in Stir and mix evenly with a ratio of 10:1 to prepare white liquid silicone rubber; slowly pour the uniformly mixed liquid silicone rubber into the mold, close the mold and compact it, heat to 80°C for 5 hours, and then take out the plate after cooling and demoulding. Trim the corners to get a 14mm thick white deformable composite insulation board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com