A method for synthesizing nano-zinc silicate luminescent material by using waste silicon powder hydrothermal method

A luminescent material, zinc silicate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of complex reaction methods and narrow reactants, and achieve the effects of simple and easy method, expansion of scope, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

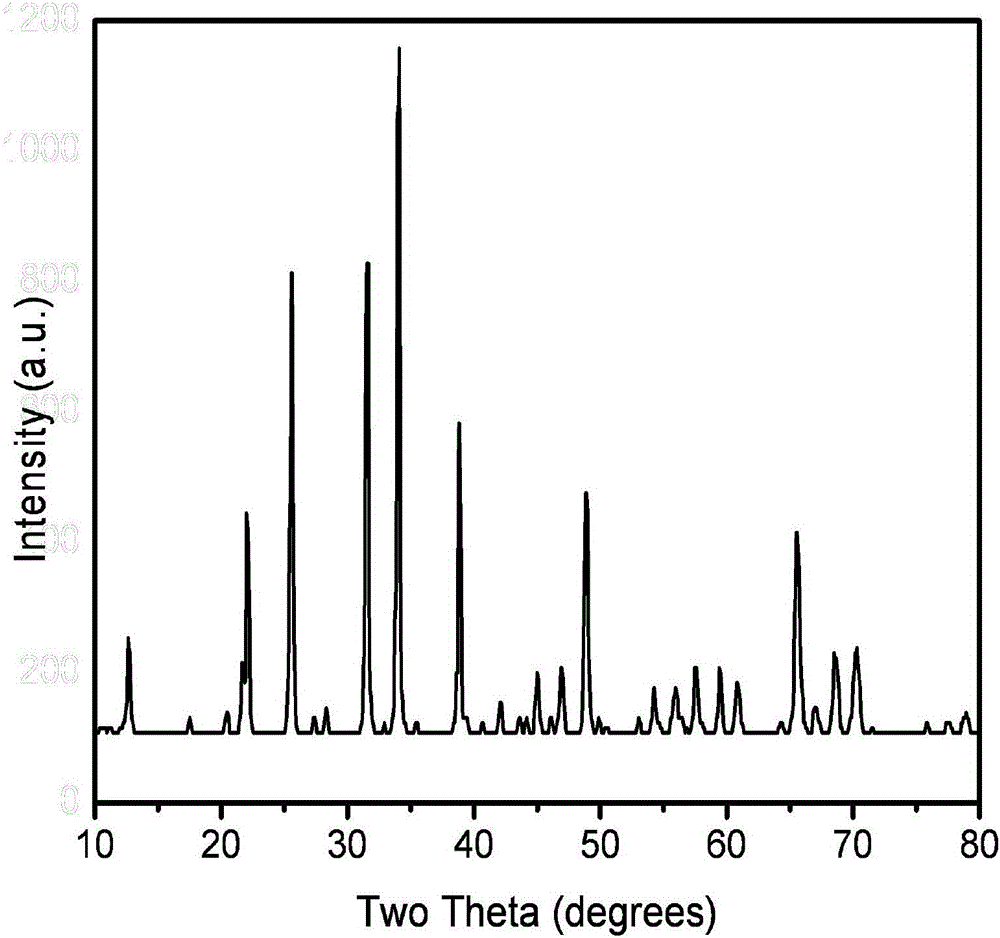

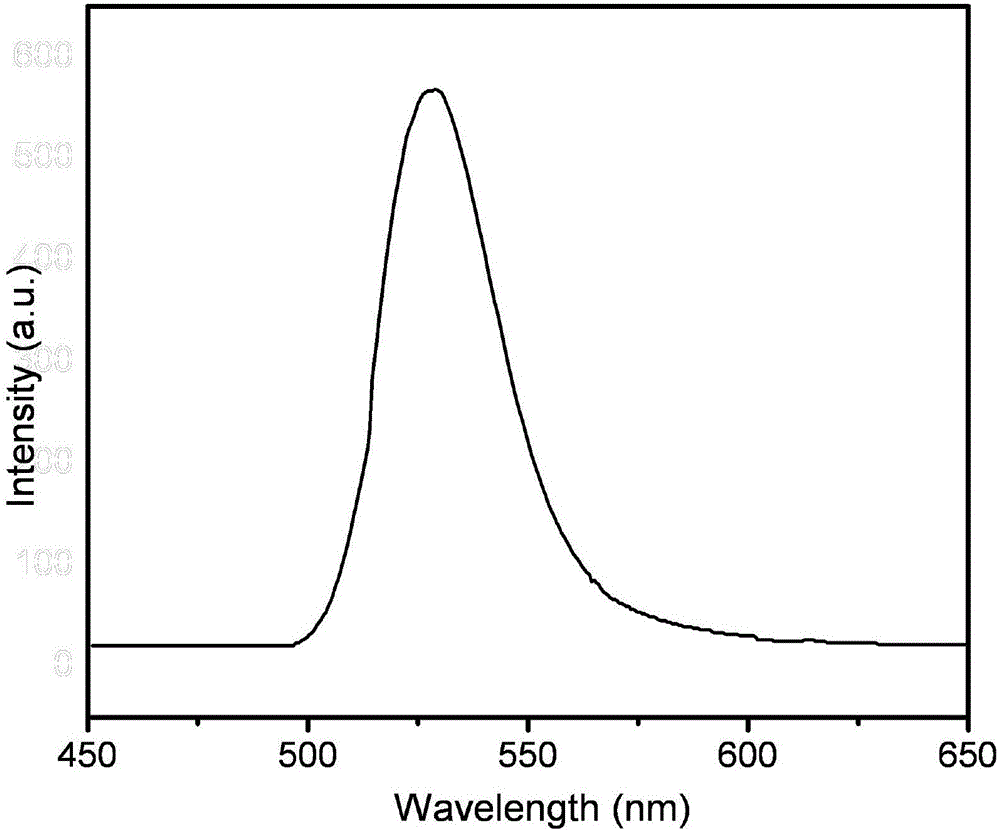

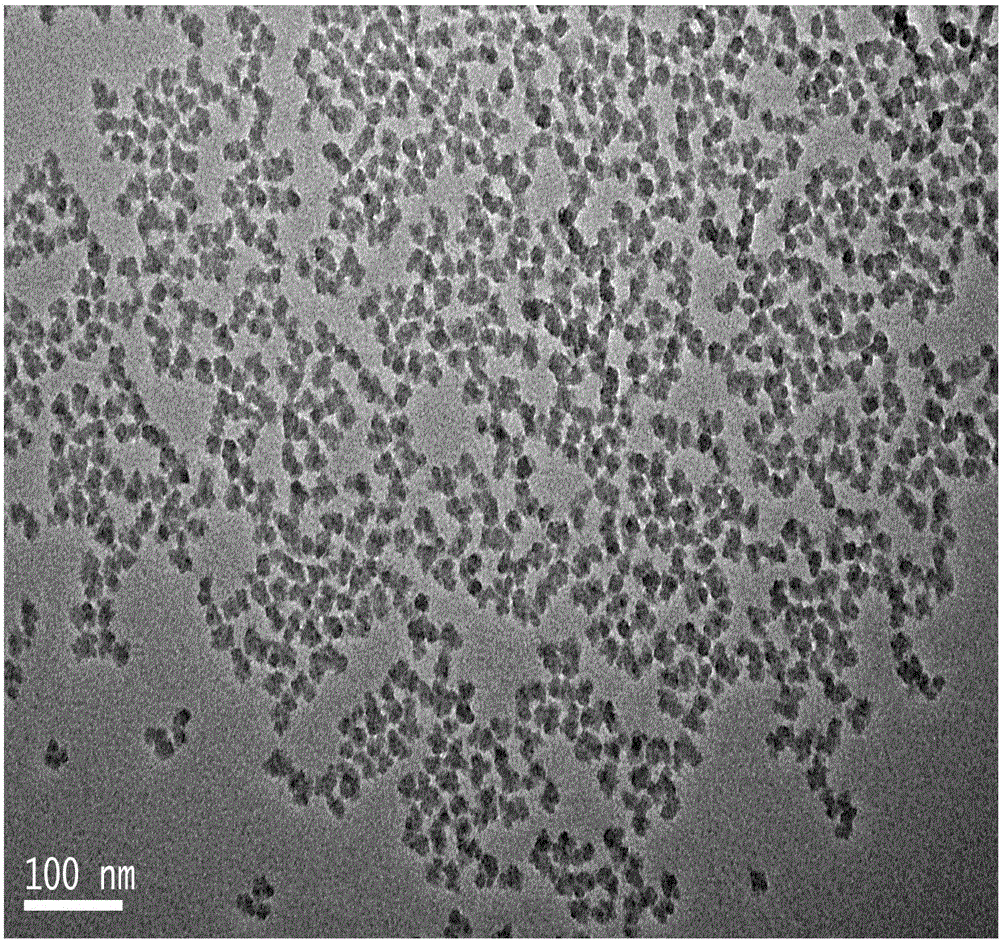

[0024] 4.65gZn(CH 3 COO) 2 2H 2 O, 0.01gMn(NO 3 ) 2 4H 2 O, 0.05g cetyltrimethylammonium bromide, dissolved in 50ml deionized water, add 0.56g waste silicon powder, stir for 15 minutes, then add 0.01g NaOH, stir for 10 minutes, transfer the above mixture to the lining Put it in a 100ml polytetrafluoroethylene reaction kettle, seal the reaction kettle, put it in an oven at 130°C for 48 hours, take it out to cool naturally, wash the product with distilled water, centrifuge, and dry naturally to obtain silicic acid Zinc luminescent material 4.22g, the product is green under the excitation of 254nm ultraviolet light.

Embodiment 2

[0026] 4.60gZn(CH 3 COO) 2 2H 2 O, 0.02gMn(NO 3 ) 2 4H 2 O, 0.05g cetyltrimethylammonium bromide, dissolved in 50ml deionized water, add 0.56g waste silicon powder, stir for 15 minutes, then add 0.01g NaOH, stir for 10 minutes, transfer the above mixture to the lining Put it in a 100ml polytetrafluoroethylene reaction kettle, seal the reaction kettle, put it in an oven at 130°C for 48 hours, take it out to cool naturally, wash the product with distilled water, centrifuge, and dry naturally to obtain silicic acid Zinc luminescent material 4.20g, the product is green under the excitation of 254nm ultraviolet light.

Embodiment 3

[0028] 4.95gZn(CH 3 COO) 2 2H 2 O, 0.01gMn(NO 3 ) 2 4H 2 O, 0.05g of cetyltrimethylammonium bromide, dissolved in 50ml of deionized water, add 0.55g of waste silicon powder, stir for 15 minutes, then add 0.01g of NaOH, stir for 10 minutes, transfer the above mixture to the lining Put it in a 100ml polytetrafluoroethylene reaction kettle, seal the reaction kettle, put it in an oven at 200°C for 12 hours, take it out to cool naturally, wash the product with distilled water, centrifuge, and dry naturally to obtain silicic acid Zinc luminescent material 4.02g, the product is green under the excitation of 254nm ultraviolet light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com