A kind of oil sludge modifier and its preparation method and application

A modifier and oil sludge technology, applied in chemical instruments and methods, sludge treatment, petroleum industry, etc., can solve the problems of low treatment efficiency, environmental re-pollution, high investment cost, etc., to increase specific surface area, content distribution The ratio is reasonable and the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention provides the preparation method of the oil sludge modifier described in the first aspect of the present invention in the second aspect, described method comprises the steps:

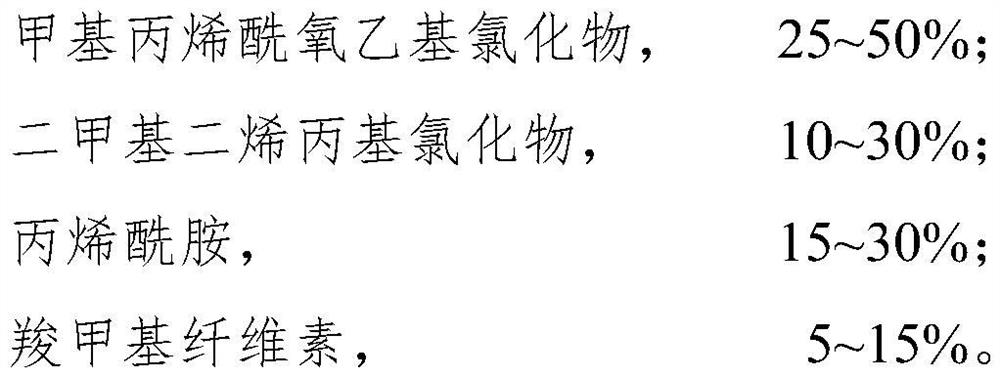

[0047] (1) Mix the methacryloyloxyethyl chloride, the dimethyl diallyl chloride, the acrylamide and the carboxymethyl cellulose uniformly (for example, stir and mix uniformly), to obtain the curing agent;

[0048] (2) Add the auxiliary material, the calcium oxide, the bentonite and the cement to the curing agent obtained in step (1) and mix them uniformly (for example, stir and mix uniformly) to obtain the oil sludge modifier.

[0049] The preparation process of the sludge modifier described in the present invention is simple, low in cost, and less in energy consumption. Treating the sludge with the sludge modifier requires simple equipment, simple operation, low energy consumption, low cost, and does not produce Second muddying.

[0050] According to some preferred embodim...

Embodiment 1

[0062] ① Mix methacryloyloxyethyl trimethyl ammonium chloride, dimethyl diallyl ammonium chloride, acrylamide and carboxymethyl cellulose in a mass ratio of 40%: 25%: 25%: 10% Evenly, to obtain a curing agent.

[0063] ② Add auxiliary materials (straw), calcium oxide, bentonite and cement to the curing agent obtained in step ① and mix uniformly to obtain a sludge modifier; wherein, the auxiliary materials, the curing agent, the calcium oxide, the The mass ratio of said bentonite and said cement is 66.5%: 16.5%: 6%: 9%: 2%.

[0064] ③ mixing waste oil and dewatered sludge (moisture content 15%) to obtain primary mixed sludge with an oil content of 40%, then adding the sludge modifier obtained in step ② to the primary mixed sludge and mixing evenly to obtain Pretreated oil sludge; wherein, the mass ratio of the primary mixed oil sludge to the oil sludge modifier is 100:20; wherein, the waste oil and the dewatered sludge can, for example, be treated with the layered oil sludge d...

Embodiment 2

[0068] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0069] ① Mix methacryloyloxyethyl trimethyl ammonium chloride, dimethyl diallyl ammonium chloride, acrylamide and carboxymethyl cellulose in a mass ratio of 35%: 25%: 25%: 15% Evenly, the curing agent is obtained.

[0070] ② Add auxiliary materials (straw), calcium oxide, bentonite and cement to the curing agent obtained in step ① and mix uniformly to obtain a sludge modifier; wherein, the auxiliary materials, the curing agent, the calcium oxide, the The mass ratio of said bentonite and said cement is 50%: 27%: 6%: 12%: 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com