A kind of method for preparing slyton perovskite type nitrogen oxide powder

A nitrogen oxide and perovskite-type technology, which is applied in chemical instruments and methods, tantalum compounds, inorganic chemistry, etc., can solve the problems of time-consuming and limited production of SLYTON powder, and achieve good dispersion, low impurity content, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

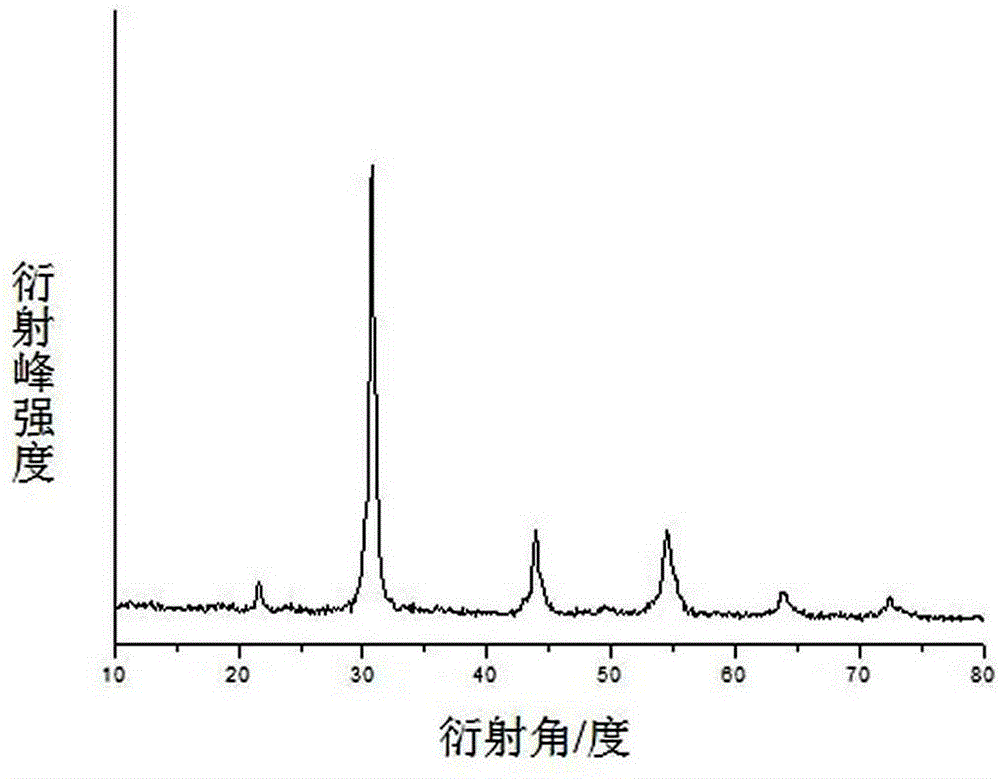

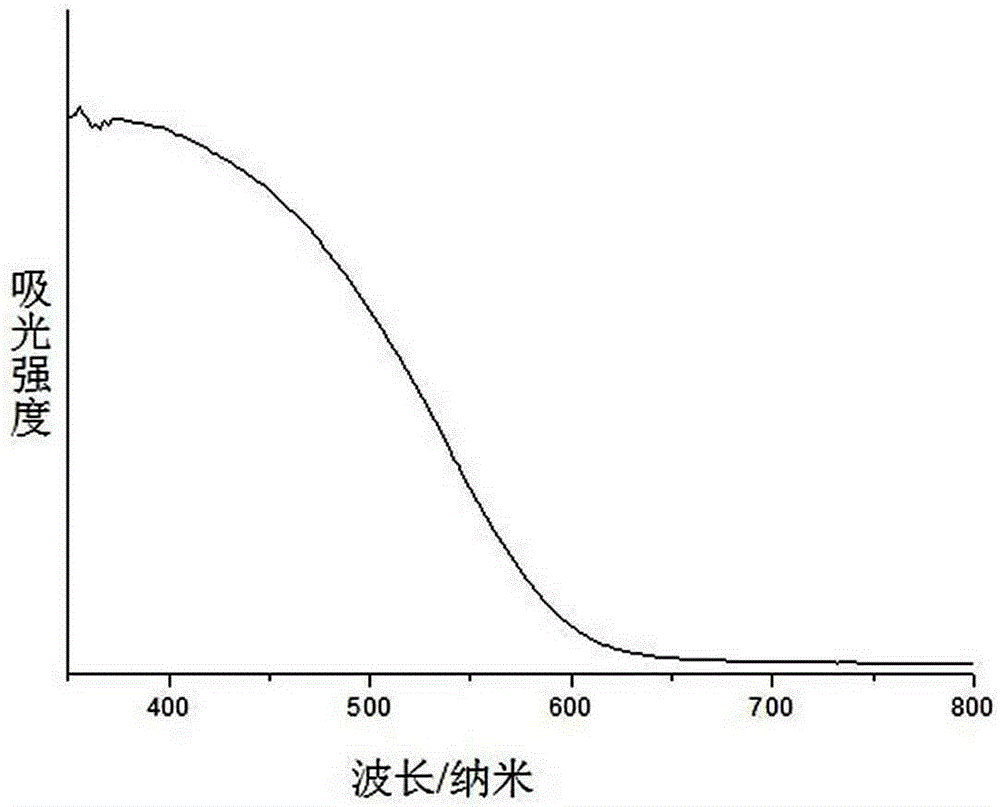

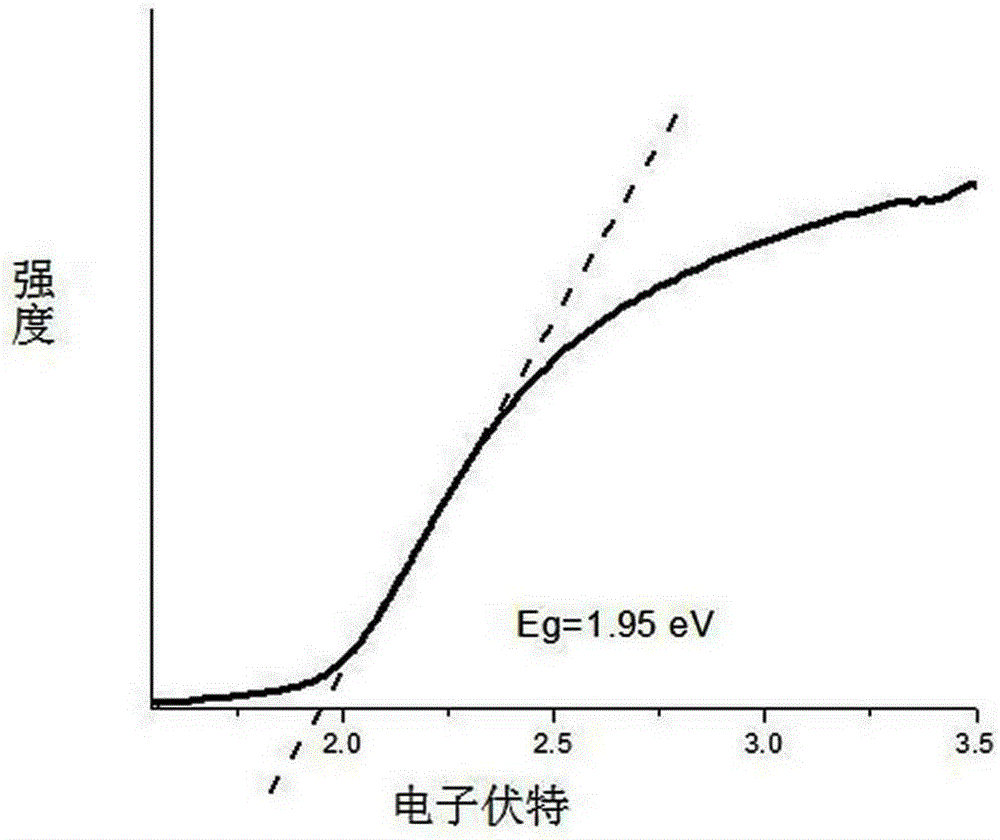

Embodiment 1

[0031] Put strontium nitrate, lanthanum nitrate, yttrium nitrate, tantalum pentachloride and urea in a molar ratio of 1:1:1:1:20, accurately weigh them and put them into methanol aqueous solution (alcohol-water volume ratio 1:1) and stir to dissolve , the time is greater than 30 minutes. The above-mentioned mixture is directly put into the muffle furnace after being packed into a large crucible, the heating rate of the programmed temperature rise is 10°C / min, the high temperature setting temperature is 800°C, and the holding time of the high temperature stage is 4h. After natural cooling, the Get precursors. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 6 hours. After cooling, SLYTON powder is obtained. The purity of its products is not less than 99.86%, and the impurity content: carbon is less than 0.12%; chlorine is less than 0.01%.

Embodiment 2

[0033] Put strontium nitrate, lanthanum nitrate, yttrium nitrate, tantalum pentachloride and urea in a molar ratio of 1:1:1:1:50, accurately weigh them and put them into methanol aqueous solution (volume ratio of alcohol to water: 2:1) and stir to dissolve , the time is greater than 30 minutes. The above-mentioned mixture is directly put into the muffle furnace after being packed into a large crucible, the heating rate of the programmed temperature rise is 10°C / min, the high temperature setting temperature is 800°C, and the holding time of the high temperature stage is 6h. After natural cooling, the Get precursors. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 7 hours. After cooling, SLYTON powder is obtained. The purity of its products is not less than 99.85%, and the impurity content: carbon is less than 0.13%; chlorine is less than 0.01%.

Embodiment 3

[0035] Put strontium nitrate, lanthanum nitrate, yttrium nitrate, tantalum pentachloride and citric acid in a molar ratio of 1:1:1:1:20, accurately weigh them and put them into methanol aqueous solution (alcohol-water volume ratio 1:1) and stir Dissolved for more than 30 minutes. The above-mentioned mixture is directly put into the muffle furnace after being packed into a large crucible, the heating rate of the programmed temperature rise is 10°C / min, the high temperature setting temperature is 800°C, and the holding time of the high temperature stage is 4h. After natural cooling, the Get precursors. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 6 hours. After cooling, SLYTON powder is obtained. The purity of its products is not less than 99.84%, and the impurity content: carbon is less than 0.14%; chlorine is less than 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com