Marine component protective coating and construction method thereof

A technology of protective coating and construction method, applied in the field of protective coating of marine components and its construction, can solve the problems of adhesion, toughness and corrosion resistance that cannot meet long-term use and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

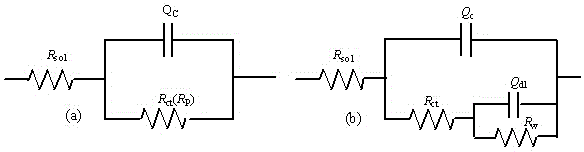

Method used

Image

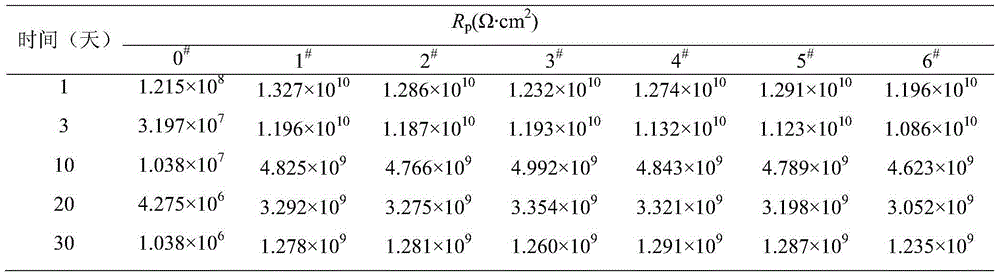

Examples

Embodiment 1

[0018] Use sandpaper to polish the steel plate and remove rust, then ultrasonically clean in acetone for 2 minutes, ultrasonically clean in anhydrous ethanol / water (volume ratio 1:1) saturated sodium hydroxide solution for 2 minutes, and ultrasonically clean in chloroform for 2 minutes. Rinse well. Pass high-purity nitrogen in an aqueous solution containing 0.1 mol / L pyrrole and 0.1 mol / L sodium dodecyl sulfonate for 10 minutes, use steel plate as working electrode, saturated calomel electrode as reference electrode, and graphite plate as auxiliary electrode. Potentiostatic polymerization at 0.8V for 2 minutes to obtain a polypyrrole film with a thickness of 10μm; then 3 coats of ES301 solvent-free epoxy resin coating from Youlong (Beijing) Heavy Anti-corrosion Coating Co., Ltd. were applied and cured for 24 hours. The dry film thickness was 800μm, and then brush 2 coats of Shandong Keyao Chemical Co., Ltd. VA-1018 epoxy acrylic topcoat, leave it to cure for 36 hours, the dry f...

Embodiment 2

[0021] Use sandpaper to polish the steel plate to remove rust, then ultrasonically clean in acetone for 2 minutes, ultrasonically clean in anhydrous ethanol / water (volume ratio 1:1) saturated sodium hydroxide solution for 5 minutes, and ultrasonically clean in chloroform for 3 minutes, Rinse well. In an aqueous solution containing 0.1 mol / L pyrrole and 0.1 mol / L sodium dodecyl sulfonate, pass high-purity nitrogen for 5 minutes, use the steel plate as the working electrode, the saturated calomel electrode as the reference electrode, and the steel plate as the auxiliary electrode. Potentiostatic polymerization at 0.9V for 3 minutes to obtain a polypyrrole film with a thickness of 25μm; then 3 coats of Huachuan HCH01-18 epoxy resin coating were applied and cured for 24 hours, the dry film thickness was 600μm, and then 2 coats of Tianjin Andron Technology company DM-102 epoxy acrylic topcoat, placed and cured for 36 hours, the dry film thickness of the coating is 130μm.

[0022] Aft...

Embodiment 3

[0024] Pre-grind the workpiece with sandpaper to remove rust, then ultrasonically clean in acetone for 1 min, ultrasonically clean in anhydrous ethanol / water (volume ratio 1:1) saturated sodium hydroxide solution for 3 minutes, and ultrasonically clean in chloroform for 3 minutes. Rinse well. Pass high-purity nitrogen in an aqueous solution containing 0.1mol / L pyrrole and 0.1mol / L sodium dodecyl sulfonate for 3 minutes, use steel plate as working electrode, saturated calomel electrode as reference electrode, and platinum plate as auxiliary electrode. Potentiostatic polymerization at 1.0V for 5 minutes to obtain a polypyrrole film with a thickness of 30μm; then spray Akzo Nobel Powder Coating Ningbo Co., Ltd. epoxy powder coating for 2 coats, cure at 180°C for 20 minutes, and dry film thickness of 240μm. Two coats of XJ-4003 polyurethane acrylic paint from Sichuan Xingyuan Special Coating Co., Ltd., with a dry film thickness of 400μm.

[0025] After the above-mentioned painting c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com