Laser scanning method for rapid prototyping of superalloy structural parts

A high-temperature alloy and laser scanning technology, applied in the field of metal powder melting and forming, to achieve a high degree of controllability, improve mechanical properties and surface accuracy, and be suitable for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

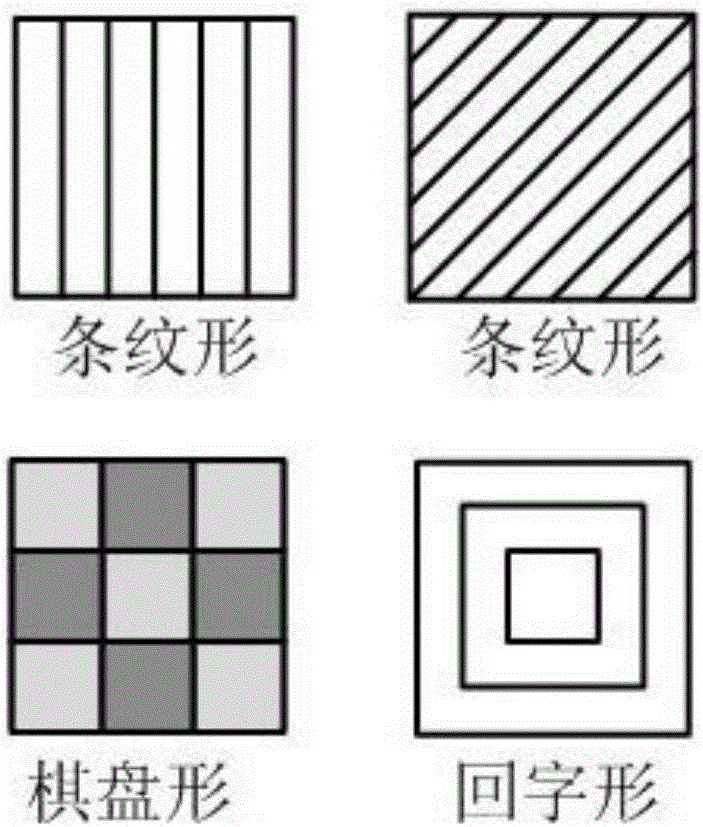

[0032] A high-temperature alloy slice layer is divided into three areas A1, B1, and C1, and the area S of the A1 area is 0.15mm 2 , using the "back" shape scanning method, the area S of B1 area is 0.5mm 2 , using the stripe-shaped scanning method, the area S of the C1 area is 2.0mm 2 , using the checkerboard scanning method;

[0033] The particle size of the powder is 20 μm, and the layer thickness is 50 μm;

[0034] The scanning power of the laser is 200W, the scanning speed is 600mm / s, the scanning point distance is 20μm, and the scanning distance is 0.1m during the forming scanning; the scanning power of the laser is 150W, the scanning speed is 1000mm / s, and the scanning point distance is 10μm. Scanning distance 0.05mm;

[0035] The laser wavelength range is 980nm, and the protective gas is argon.

Embodiment 2

[0037] A high-temperature alloy slice layer is divided into three areas: A2, B2, and C2, and the thickness H of the structural part in the scanning area of A2 is 0.4mm 2 , using the "back" shape scanning method, the thickness H of the structural part in the B2 scanning area is 1.0mm 2 , using the stripe-shaped scanning method, the thickness H of the structural part in the C2 scanning area is 6mm 2 , using the checkerboard scanning method;

[0038] The particle size of the powder is 25 μm, and the layer thickness is 45 μm;

[0039] The scanning power of the laser is 250W, the scanning speed is 700mm / s, the scanning point pitch is 30μm, and the scanning spacing is 0.2m during the forming scanning; the scanning power of the laser is 160W, the scanning speed is 1100mm / s, and the scanning point pitch is 15μm when scanning the outer surface. Scanning distance 0.06mm;

[0040] The laser wavelength range is 1.07μm, and the protective gas is argon.

Embodiment 3

[0042] A high-temperature alloy slice layer is divided into three areas A3, B3, and C3, and the area S of the A3 area is 0.1mm 2 , using the "back" shape scanning method, the area S of B3 area is 0.8mm 2 , using the stripe-shaped scanning method, the area S of the C3 area is 3.0mm 2 , using the checkerboard scanning method;

[0043] The particle size of the powder is 30 μm, and the layer thickness is 45 μm;

[0044] The scanning power of the laser is 400W, the scanning speed is 1000mm / s, the scanning point pitch is 50μm, and the scanning spacing is 0.5m during the forming scanning; the scanning power of the laser is 200W, the scanning speed is 1500mm / s, and the scanning point pitch is 30μm when scanning the outer surface. Scanning distance 0.2mm;

[0045] The laser wavelength range is 9.6 μm, and the protective gas is argon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com