Modified manganese-based layered material, preparation method thereof, and lithium-ion battery containing the material

A basic and modified technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor material cycle at room temperature and high temperature, changes in material surface composition and structure, restricting the commercial application of materials, etc., to improve electron transport. Speed, short transmission path, good batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An embodiment of the present invention provides a method for preparing a modified manganese-based matrix material, the preparation method comprising:

[0032] Dissolve an appropriate amount of soluble lithium source compound, soluble phosphorus source compound, soluble manganese source compound, acidic complexing agent, and soluble sugar in deionized water and stir for 1-10 hours to make a sol, in which lithium, manganese, and phosphorus are three elements The molar ratio is 0.95-1:1:1, the molar ratio of phosphorus element to the manganese-based matrix material to be modified is 0.05-0.30:1, the pH value of the sol solution is 4-6, and the mass of carbon element in soluble sugars 1-30% of the mass of the manganese-based matrix material to be modified;

[0033] Adding the manganese-based matrix material to be modified into the prepared sol, stirring and mixing, heating while stirring until the sol evaporates to dryness, and obtaining a modified manganese-based matrix ma...

Embodiment 2

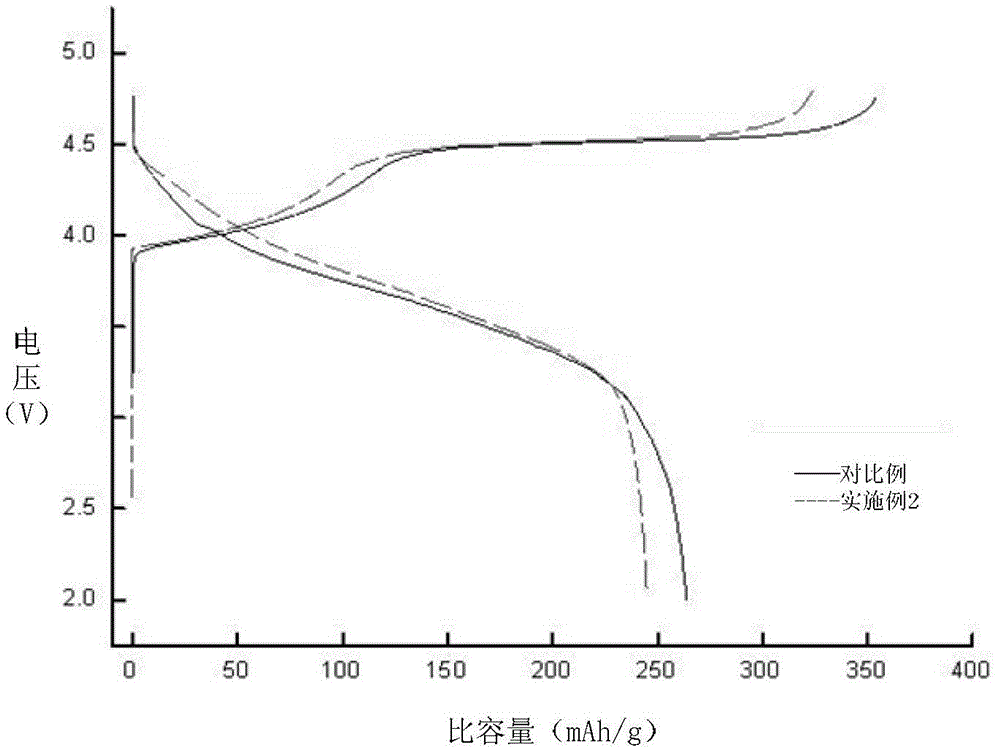

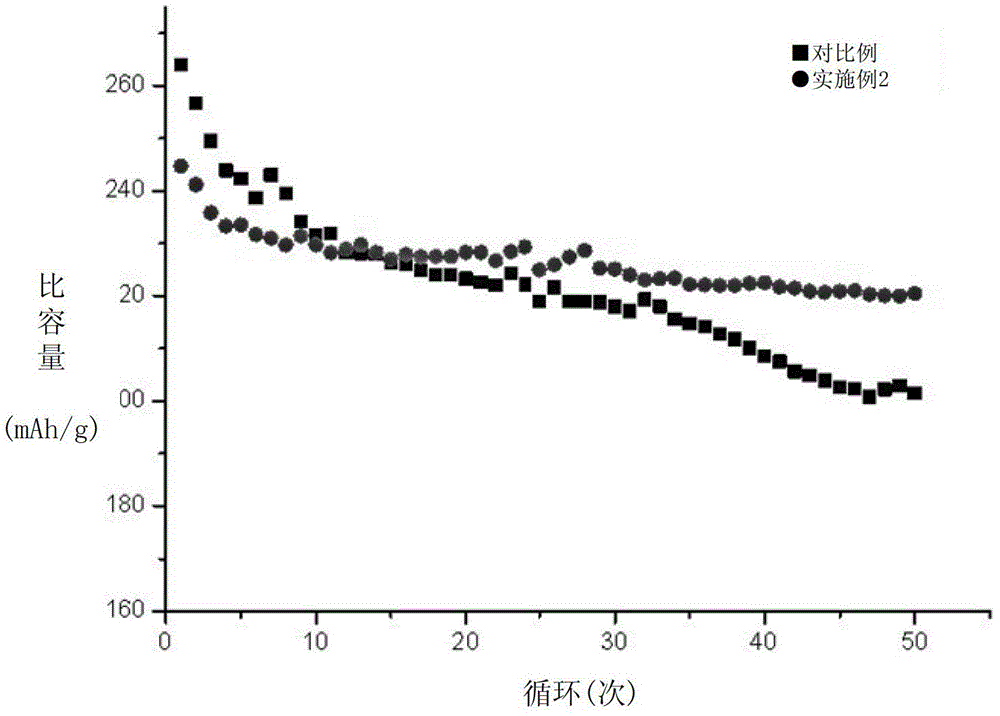

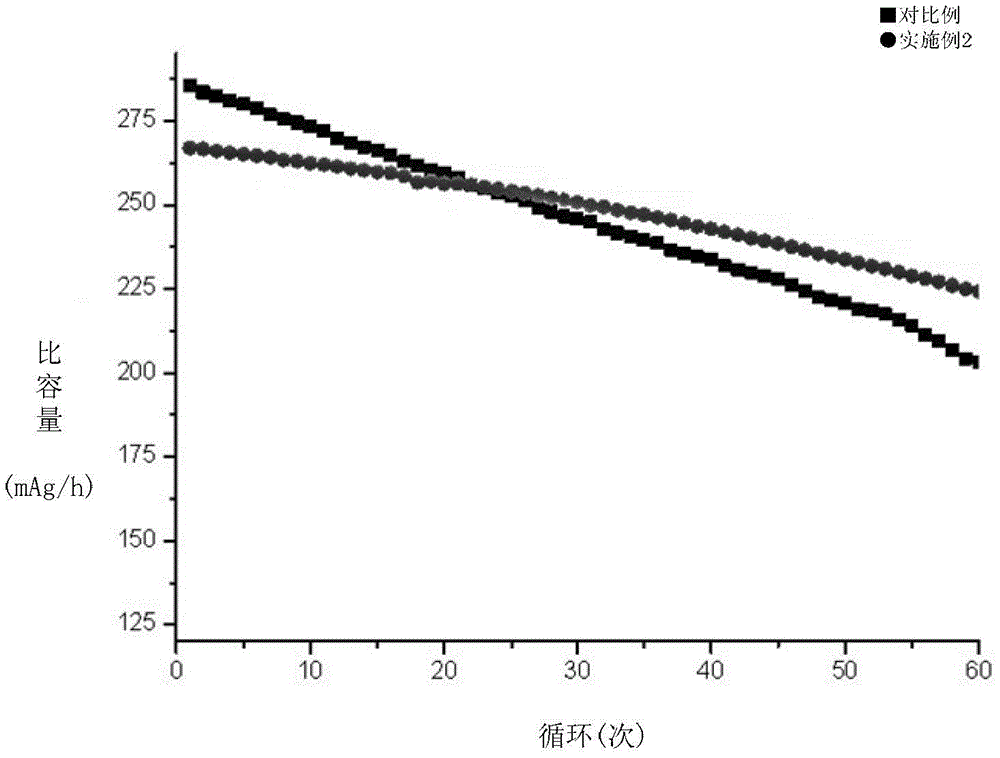

[0050] Add 4.2g of lithium hydroxide, 13.2g of diammonium hydrogen phosphate, and 24.5g of manganese acetate into a beaker, add 200ml of deionized water, add citric acid to adjust the pH value to pH=5, add 26.7g of glucose and stir for 5 hours to make a sol;

[0051] 106.7g manganese-based layered material 0.5Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Add it into the sol, continue stirring and mixing for 10 hours, then stir while heating in a water bath, until the sol is completely evaporated to dryness, and obtain the precursor of the modified manganese-based matrix material;

[0052] Put the above-mentioned modified manganese-based matrix material precursor into an oven and dry at 120°C for 4 hours, take it out and pass through a 200-mesh sieve, put the undersieve into a muffle furnace, and bake it at 300°C under nitrogen protection 4h, then increase the temperature and roast at 750°C for 16h, then cool down to room temperature, take out the material cooled to room temper...

Embodiment 3

[0054] Add 4.2g of lithium hydroxide, 13.2g of diammonium hydrogen phosphate, and 24.5g of manganese acetate into a beaker, add 200ml of deionized water, add citric acid to adjust the pH value to pH=5, add 26.7g of glucose and stir for 5 hours to make a sol ;

[0055] 213.4g manganese-based layered material 0.5Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Add it into the sol, continue to stir for 10 hours, and then stir while heating in a water bath until the sol is completely evaporated to dryness to obtain a modified manganese-based matrix material precursor;

[0056] Put the above-mentioned modified manganese-based matrix material precursor into an oven and dry at 120°C for 4 hours, take it out and pass through a 200-mesh sieve, put the undersieve into a muffle furnace, and bake it at 300°C under nitrogen protection 4h, then increase the temperature and roast at 750°C for 16h, then cool down to room temperature, take out the material cooled to room temperature and pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com