Iron-based alloy magnetic powder core adopting core-shell heterostructure and preparation method thereof

An iron-based alloy, heterostructure technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of difficult to control the thickness control conditions of the uniform oxide insulating film, and avoid the use of organic insulating agents and binders. Use, reduce production costs and investment, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An iron-based alloy magnetic powder core with a core-shell heterostructure and a preparation method thereof. The preparation method of this embodiment is:

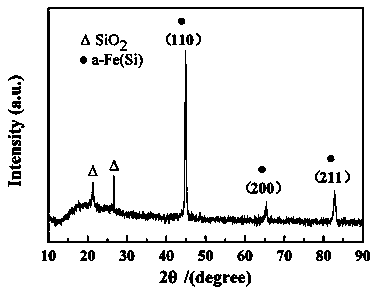

[0031] The first step is to mix 80~85wt% iron-based alloy powder and 15~20wt% SiO 2 The powder is mixed evenly, and then ball milled for 1~1.5h under the protection of argon, the mass ratio of ball to material is (10~12)︰1, the speed of the ball mill is 100~200r / min, and the iron-based Alloy composite powder.

[0032] The second step is to put the iron-based alloy composite powder with a core-shell heterogeneous structure into a graphite mold, then place the graphite mold in a plasma-activated sintering furnace, vacuumize to 0.01-0.05MPa, and inject argon gas to normal pressure; then raise the temperature to 900~950°C at a heating rate of 50~60°C / min, apply pressure to the graphite mold at an equal pressure rate to 20~25MPa, start and end time of heating and pressurization of graphite mold same time.

[0033] St...

Embodiment 2

[0042] An iron-based alloy magnetic powder core with a core-shell heterostructure and a preparation method thereof. The preparation method of this embodiment is:

[0043] The first step is to mix 85~90wt% iron-based alloy powder and 10~15wt% MgO powder evenly, and then ball mill for 1.5~2h under the protection of argon, the mass ratio of ball to material is (12~14)︰1, The speed of the ball mill is 200~300r / min, and the iron-based alloy composite powder with a core-shell heterogeneous structure is obtained.

[0044] The second step is to put the iron-based alloy composite powder with a core-shell heterogeneous structure into a graphite mold, then place the graphite mold in a plasma-activated sintering furnace, vacuumize to 0.05~0.10MPa, and inject argon gas to normal pressure; then raise the temperature to 950~1000℃ at a heating rate of 60~70℃ / min, apply pressure to the graphite mold at an equal pressure rate to 25~30MPa, start and stop time of heating and pressurization of gr...

Embodiment 3

[0054] An iron-based alloy magnetic powder core with a core-shell heterostructure and a preparation method thereof. The preparation method of this embodiment is:

[0055] The first step is to mix 90~95wt% iron-based alloy powder and 5~10wt% Al 2 o 3 The powder is mixed evenly, and then ball milled for 2~2.5h under the protection of argon, the mass ratio of ball to material is (14~16)︰1, the speed of the ball mill is 300~400r / min, and the iron-based Alloy composite powder.

[0056] In the second step, the iron-based alloy composite powder with a core-shell heterogeneous structure is loaded into a graphite mold, and then the graphite mold is placed in a plasma-activated sintering furnace, vacuumed to 0.10-0.15MPa, and nitrogen gas is introduced to Atmospheric pressure; then raise the temperature to 1000~1050℃ at a heating rate of 70~80℃ / min, apply pressure to the graphite mold at an equal pressure rate to 30~35MPa, start and end time of heating and pressurization of graphite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

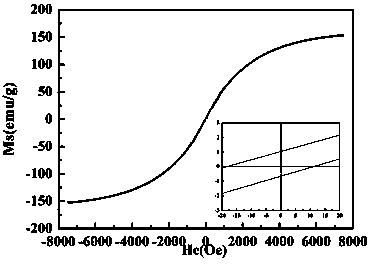

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com