Composite material for shell of toilet of high-speed train and preparation method thereof

A technology for high-speed trains and composite materials, which is applied in the field of high-speed train toilet composite material shells and its preparation, can solve the problems of large curing shrinkage and performance degradation, and achieve the effects of reducing product costs, increasing service life, and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

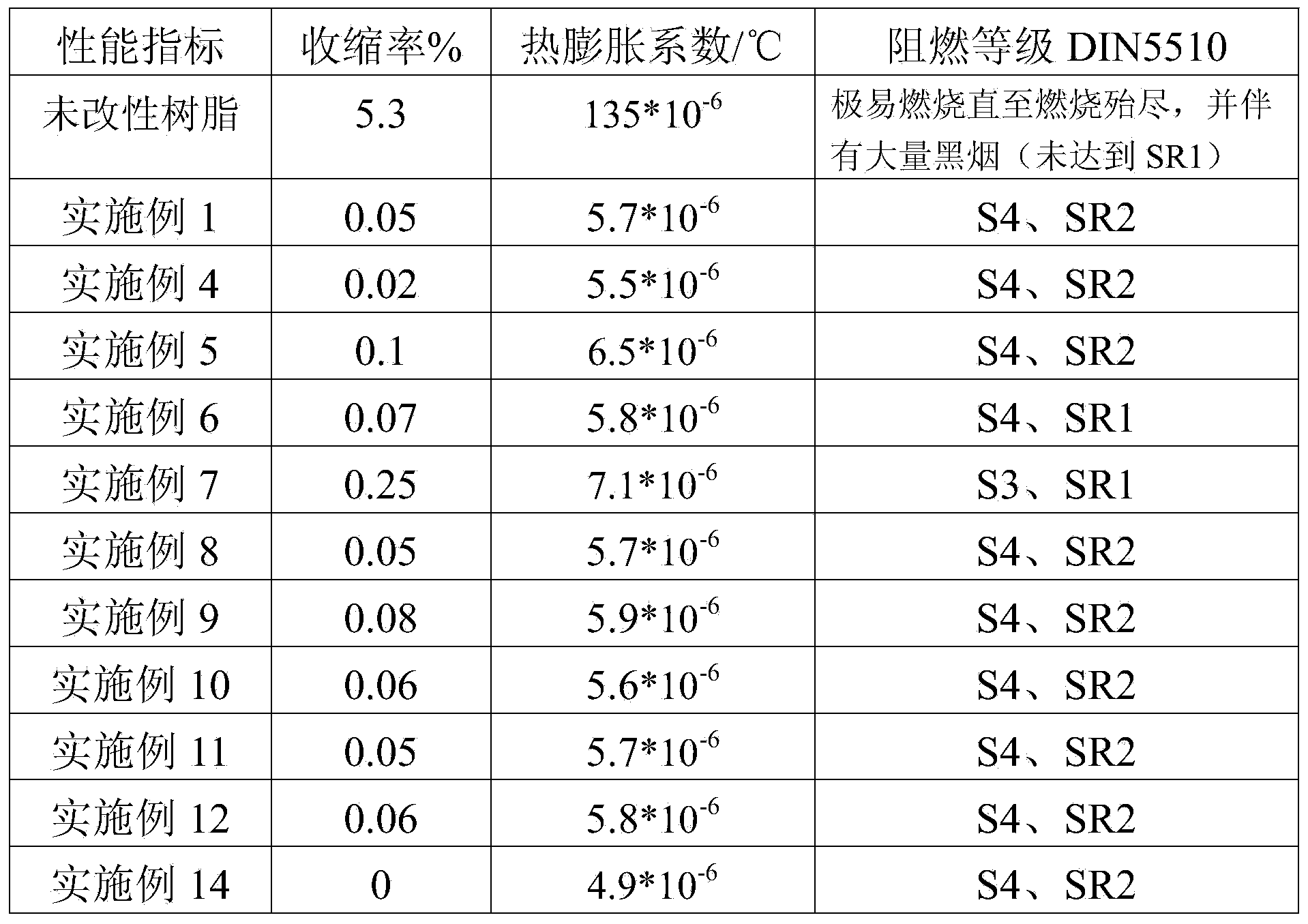

Examples

Embodiment 1

[0027] Embodiment 1: the preparation method of the high-speed train toilet composite housing of the present embodiment is carried out according to the following steps: (1) make the shell mold according to the high-speed train toilet design requirements; (2) prepare modified unsaturated polyester resin: A .Take 100 parts of unsaturated resin polyester, add 15 parts of styrene diluent to it, and stir evenly; B. Take 10 parts of zirconium tungstate and 12 parts of aluminum hydroxide powder, grind them separately and pass through a 200-mesh sieve screen. C. Surface treatment of zirconium tungstate and aluminum hydroxide solid powder with tetramethoxysilane, the mass percentage of tetramethoxysilane and solid powder is 1:50; D. Place the treated powder at 100°C Dry in a constant temperature drying oven for 2 hours; E. Grind the dried powder separately and sieve through a 200-mesh sieve; F. Add the powder into the diluted resin matrix and stir evenly; G. Take 3 parts of bentonite an...

Embodiment 2

[0029] Embodiment 2: The difference between this embodiment and embodiment 1 is that in step (2) A, 10 parts of styrene diluent are added to 100 parts of unsaturated resin polyester, and other steps are the same as embodiment 1.

Embodiment 3

[0030] Embodiment 3: the difference of this embodiment and embodiment 1 or 2 is that in the A of step (2), add 10 parts of styrene and 5 parts of acetone to 100 parts of unsaturated resin polyesters, other steps and embodiment 1 or the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com