Method for preparing 3-amino-2-methyl benzoic acid

A technology of methyl benzoic acid and amino, which is applied in chemical instruments and methods, cyanide reaction preparation, organic compound preparation, etc., can solve the problems of high environmental risk, low conversion rate, environmental pollution, etc., and achieve environmental friendliness, treatment Simple process and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

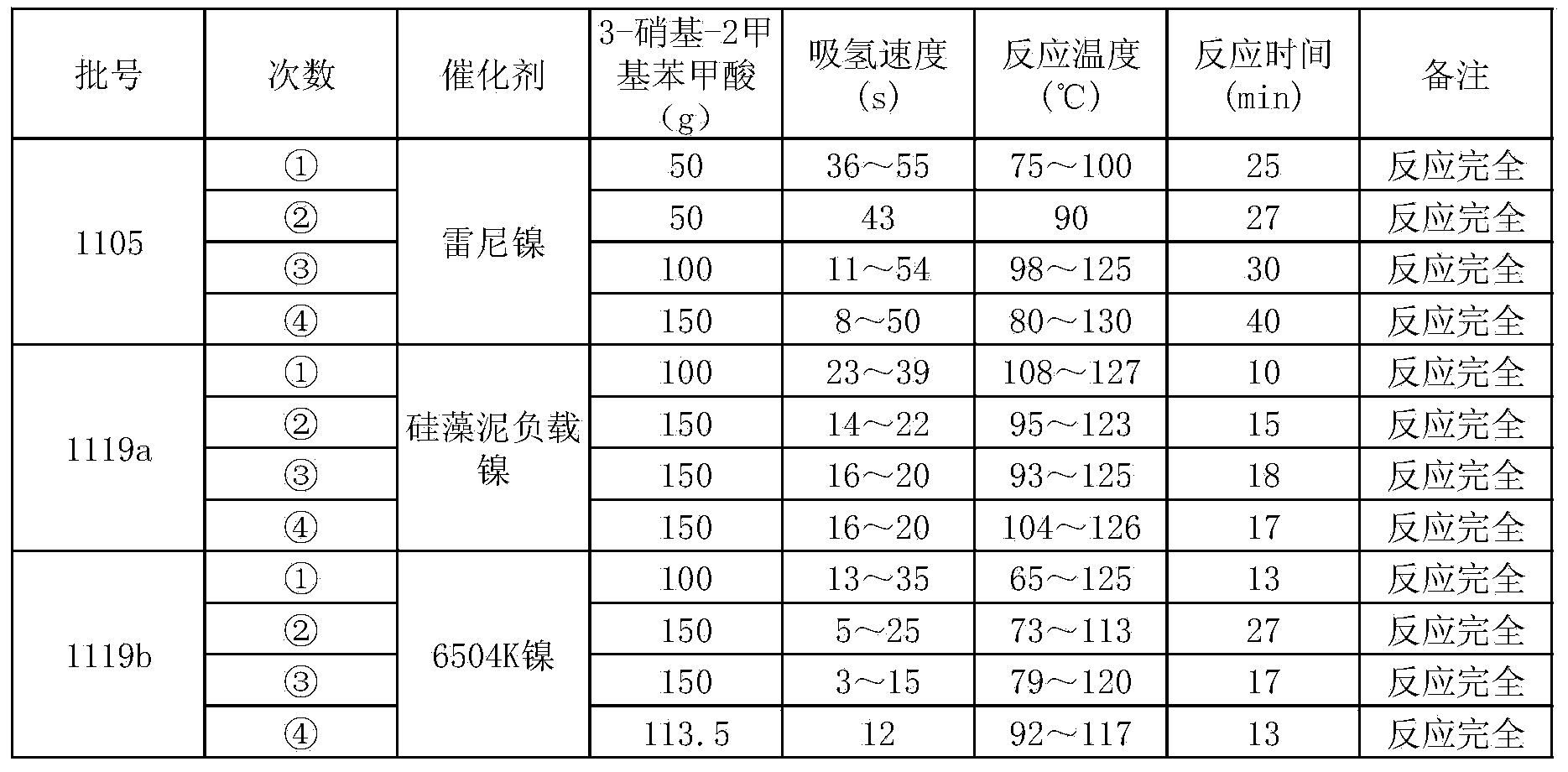

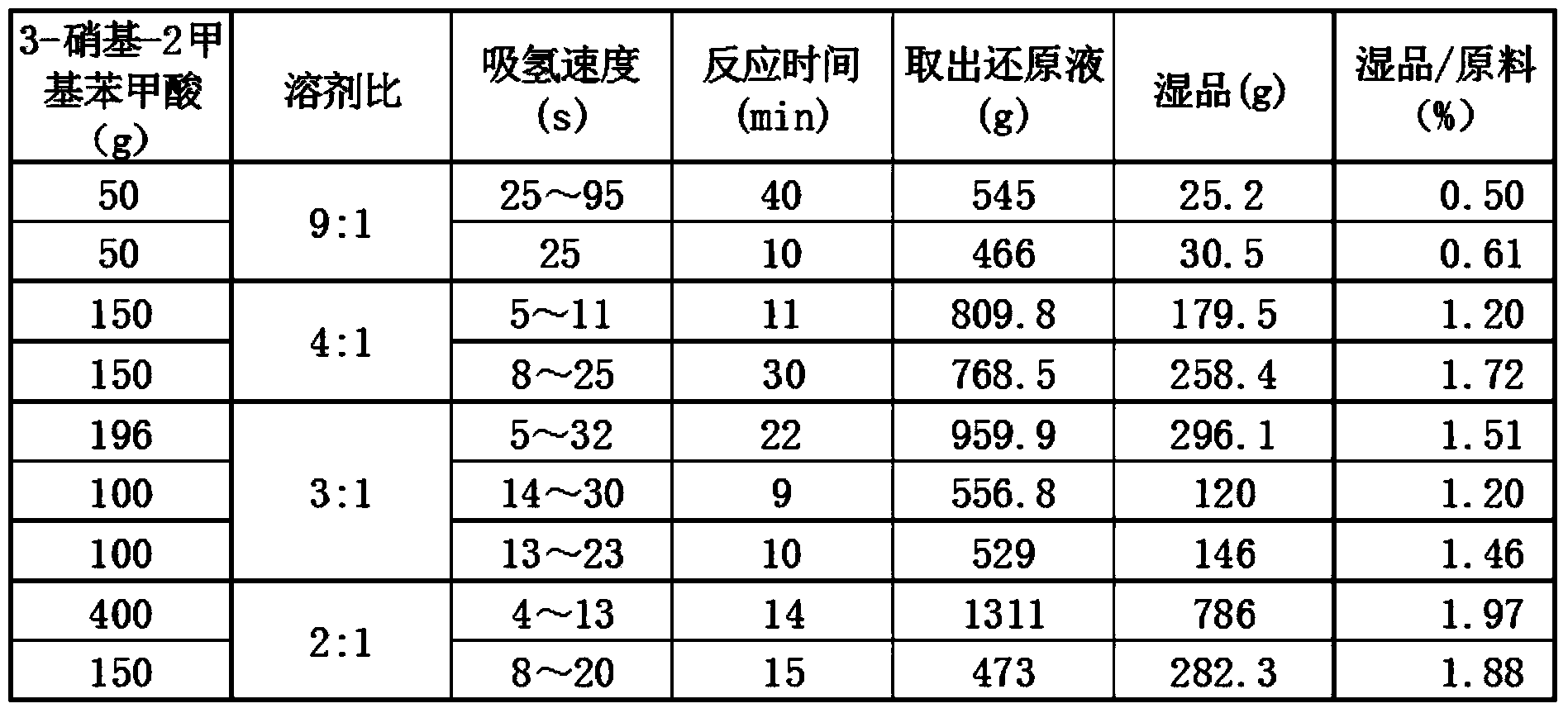

[0018] 1. Catalyst selection

[0019] Using Raney nickel catalyst, diatom ooze-supported nickel catalyst, and 6504k nickel catalyst respectively, the hydrogenation test was carried out according to the operation procedure of step (2) in Example 2, and the test data are shown in Table 1.

[0020] Table 1 Hydrogenation data table of different catalysts

[0021]

[0022] From the above data, it can be seen that it is feasible to use Raney nickel catalyst, diatom mud-supported nickel catalyst, and 6504K nickel catalyst for liquid phase hydrogenation of 3-nitro-2-methylbenzoic acid. From the perspective of hydrogen absorption speed, the absorption rate of 6504K nickel catalyst Hydrogen has the fastest speed. From the perspective of reaction time, the total reaction time of diatom ooze-supported nickel catalyst and 6504K nickel catalyst is equivalent, and the reaction time of Raney nickel catalyst is relatively long. On the whole, it is relatively better to use 6504K nickel cata...

Embodiment 1

[0034] Embodiment 1 prepares the method for 3-amino-2-methylbenzoic acid

[0035] The method for preparing 3-amino-2-methylbenzoic acid comprises the following steps:

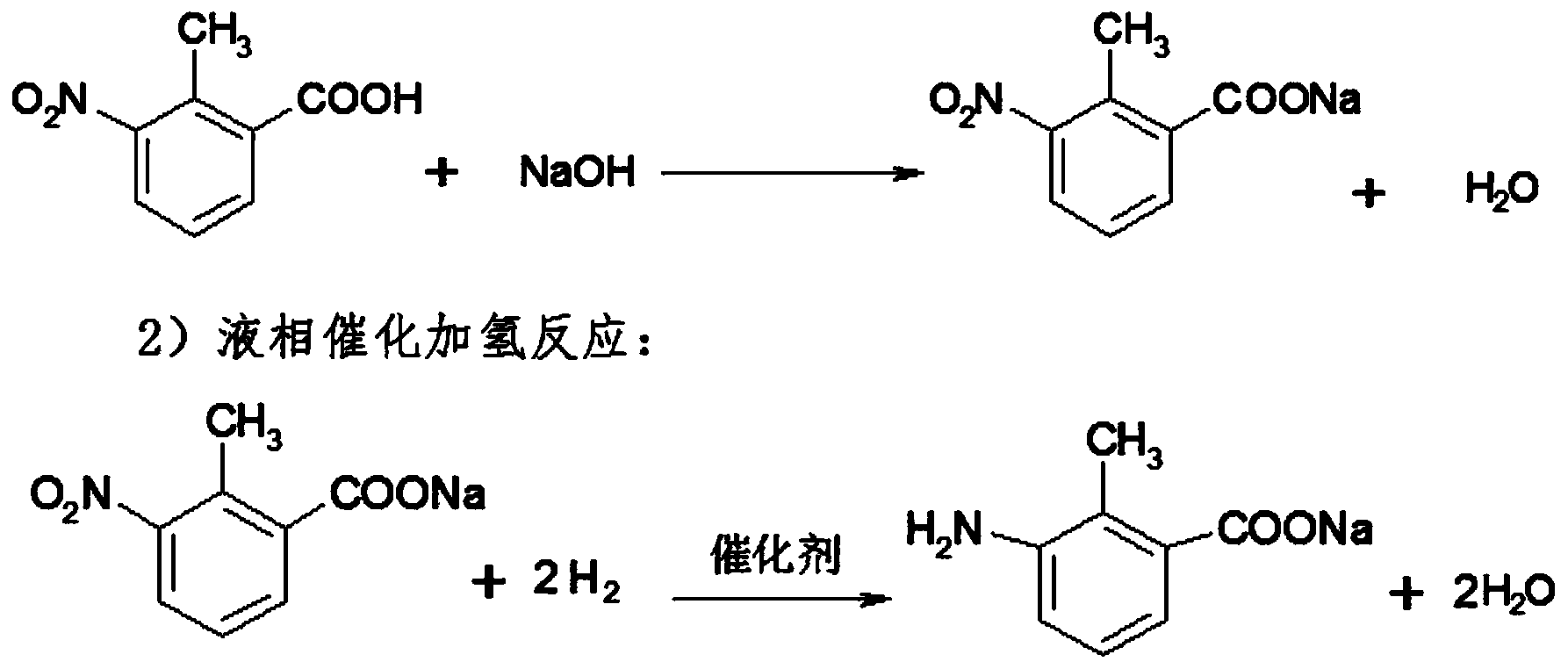

[0036] 1) Salt-forming reaction:

[0037]

[0038] The catalyst is 6504K nickel, pure water is used as the solvent in the liquid phase, and the solvent ratio is 2.5:1, the hydrogenation reaction pressure is controlled at 2.0 MPa, and the temperature is 125°C.

[0039] 3) Adjust the reducing solution obtained in step 2) to pH=5.4 with hydrochloric acid to obtain the product with a yield of over 95%.

Embodiment 2

[0040] Embodiment 2 prepares the method for 3-amino-2-methylbenzoic acid

[0041] (1) Raw material into salt

[0042] Weigh 1000g of 3-nitro-2-methylbenzoic acid, add 2000g of distilled water, stir evenly, add caustic soda (mass percentage content 99%) under stirring, adjust pH=7~8, now the solution is clear, wait for use.

[0043] (2) Hydrogenation reduction

[0044] In a 2L autoclave, add 500ml of distilled water, 10g of 6504K nickel catalyst (nickel catalyst supported by carbon powder, manufactured by Luina, Germany), control the pressure at 1.0MPa, raise the temperature to 100°C, and activate for 1h. After activation, draw out the distilled water, add 480g of 3-nitro-2-methylbenzoic acid sodium solution at 80°C, that is, 150g of 3-nitro-2-methylbenzoic acid raw material, seal the autoclave, replace it with nitrogen for 3 times, and then use hydrogen Replace 3 times, open the hydrogen inlet valve, control the pressure at 2.0MPa, start stirring to 1000n / min, raise the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com