Heat type wind speed and direction sensor based on substrate transfer process and packaging method thereof

A technology of substrate transfer, wind speed and wind direction, applied in the direction of using thermal variables to measure fluid speed, instruments, measuring devices, etc., can solve the problems of silicon wafer pollution, damage, unstable performance, etc., and reduce useless power consumption and heat loss , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

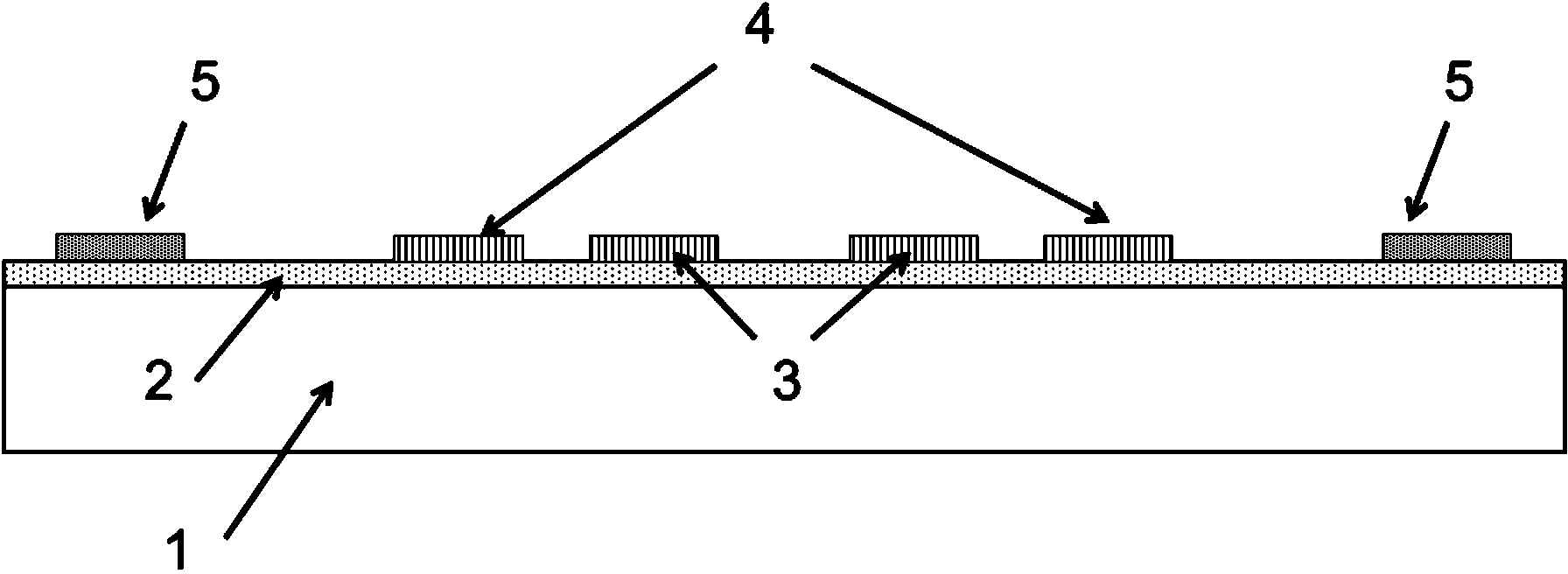

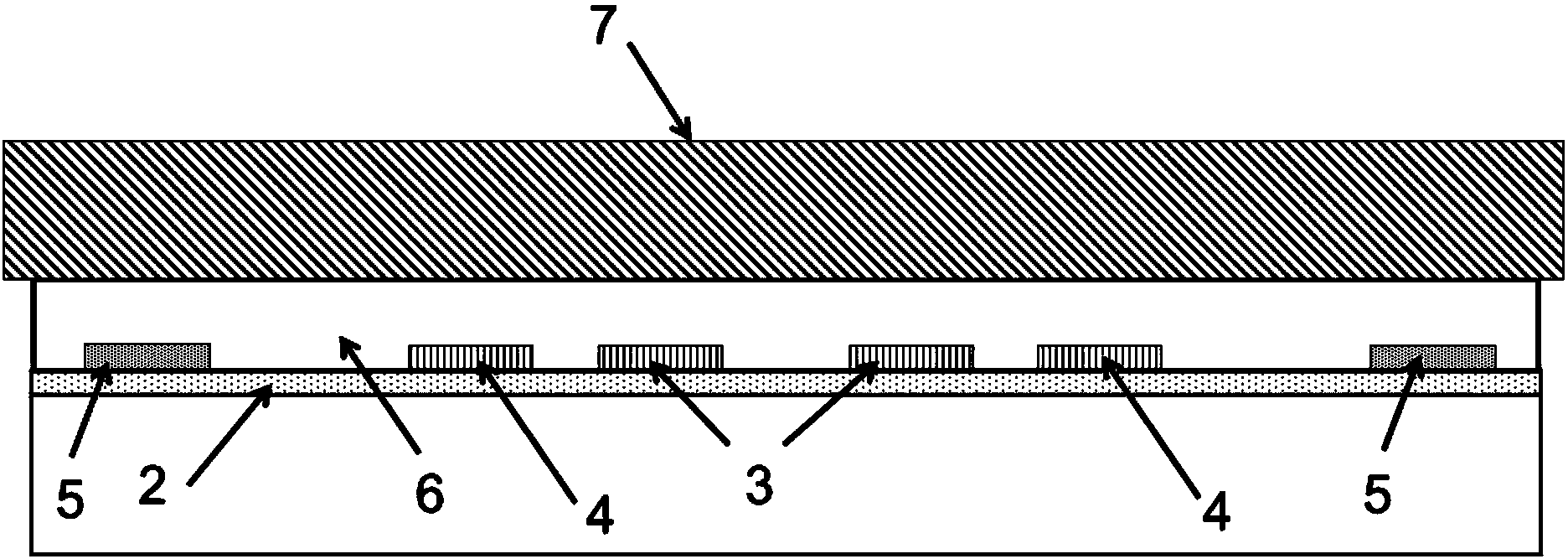

[0026] A thermal wind speed and direction sensor based on a substrate transfer process, including a ceramic substrate 7 and a sensor chip, the sensor chip includes a silicon dioxide heat insulating layer 2, and a heating element 3, a measuring The temperature element 4 and the pad 5, the front side of the silicon dioxide heat insulating layer 2 and the front side of the ceramic substrate 7 realize adhesive-based low-temperature bonding wafer-level packaging through the adhesive colloid 6; the adhesive colloid 6 is a thermally conductive material . In the sensor chip: the heating element 3 is evenly distributed around the center of the sensor chip and forms a centrosymmetric structure, forming a temperature field; the temperature measuring element 4 is also uniformly distributed around the center of the sensor chip and forms a symmetrical structure, And the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com