Solution coating continuous production equipment and method for polymer ultra-thin sub-nanofiltration composite membrane filter element

A technology for solution coating and production equipment, applied in the fields of chemical equipment and chemical technology, can solve the difficulties in the manufacture and production of sub-nano-scale porous polymer ultra-thin films, and cannot be used to prepare sub-nano-scale porous polymer ultra-thin film polymer composites. Membrane etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

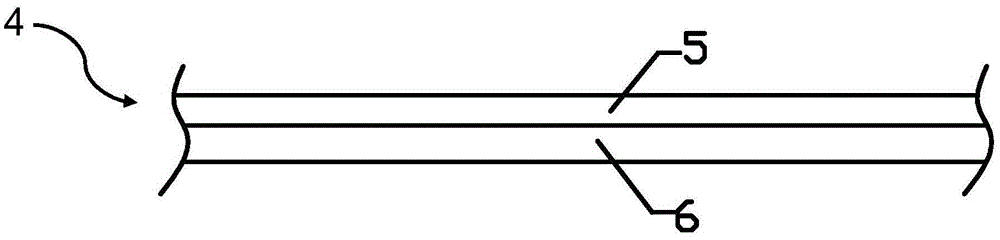

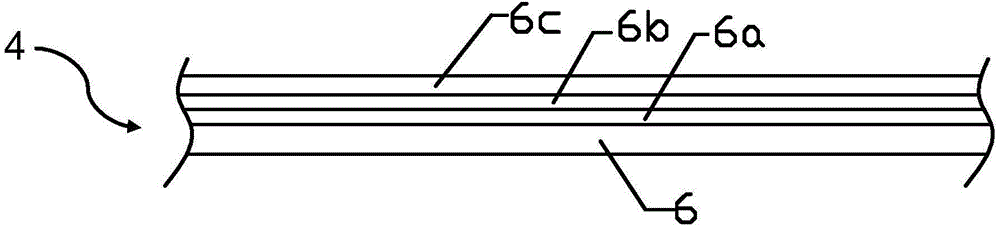

[0092] Embodiment 1: The present invention uses polyetherimide as the material of the highly breathable subnano-scale porous polymer ultra-thin film layer 5, and polyethylene terephthalate as the porous carrier layer 6. The material characteristics of the polyethylene terephthalate are as follows: the pore diameter ranges from 0.1 to 1 micron, the thickness is 0.12 mm, and the porosity is 68%. Therefore, the selected polyethylene terephthalate material has sufficient mechanical strength and air permeability, especially the pore size distribution characteristics of its excellent material characteristics are very suitable for the manufacture of high air permeability polymer ultra-thin sub-nano Filter the carrier layer of composite membrane coating, the material of described polyethylene terephthalate is a commercial raw material commonly used, therefore, the material manufacture of described polyethylene terephthalate is the technology outside the content of the present invention...

Embodiment 2

[0101] Embodiment 2: In the present invention, polyethersulfone (PES for short) is used as the material of the ultra-thin film layer 5 of a highly gas-permeable sub-nanometer porous polymer, and polytetrafluoroethylene is used as the porous carrier layer 6 . The material characteristics of the polytetrafluoroethylene are as follows: the pore diameter range is 0.05-1.2 microns, the thickness is 0.14 mm, and the porosity is 72%. Therefore, the selected polytetrafluoroethylene material has sufficient mechanical strength and gas permeability, especially the pore size distribution characteristic of its excellent material characteristics is very suitable as a coating for manufacturing ultra-thin sub-nanofiltration composite membranes of highly gas-permeable polymers. The carrier layer of the layer, the material of the polytetrafluoroethylene is a commonly used commercial raw material, therefore, the production of the material of the polytetrafluoroethylene is a technical problem beyo...

Embodiment 3

[0110] Embodiment three: the present invention uses polyethersulfone (Polyethersulfone, abbreviated as PES) as the material of the highly air-permeable sub-nanometer porous polymer ultra-thin film layer 5 of asymmetric pore size distribution, very good porous polyester non-woven fabric with air permeability Cloth serves as porous carrier layer 6 . The material characteristics of the porous polyester non-woven fabric are as follows: the pore diameter range is 0.08-1.6 microns, the thickness is 0.16 mm, and the porosity is 86%. The selected polyester material has sufficient mechanical strength and excellent air permeability, and is very suitable as the carrier layer for the ultra-thin sub-nanofiltration composite membrane coating of a highly air-permeable polymer with asymmetric pore size distribution. The ester material is a commonly used commercial raw material, therefore, the manufacture of the polyester material is a technical issue beyond the content of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com