Active clamping circuit driven by IGBT

A technology of clamping circuit and driving circuit, which is applied in the direction of circuit devices, emergency protection circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., and can solve the problem of limited driving capability of integrated driver chips and independent integrated driver chips. Electromagnetic interference, failure to meet the flexible adjustment of drive capacity and line protection capacity, etc., to avoid the effect of overvoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

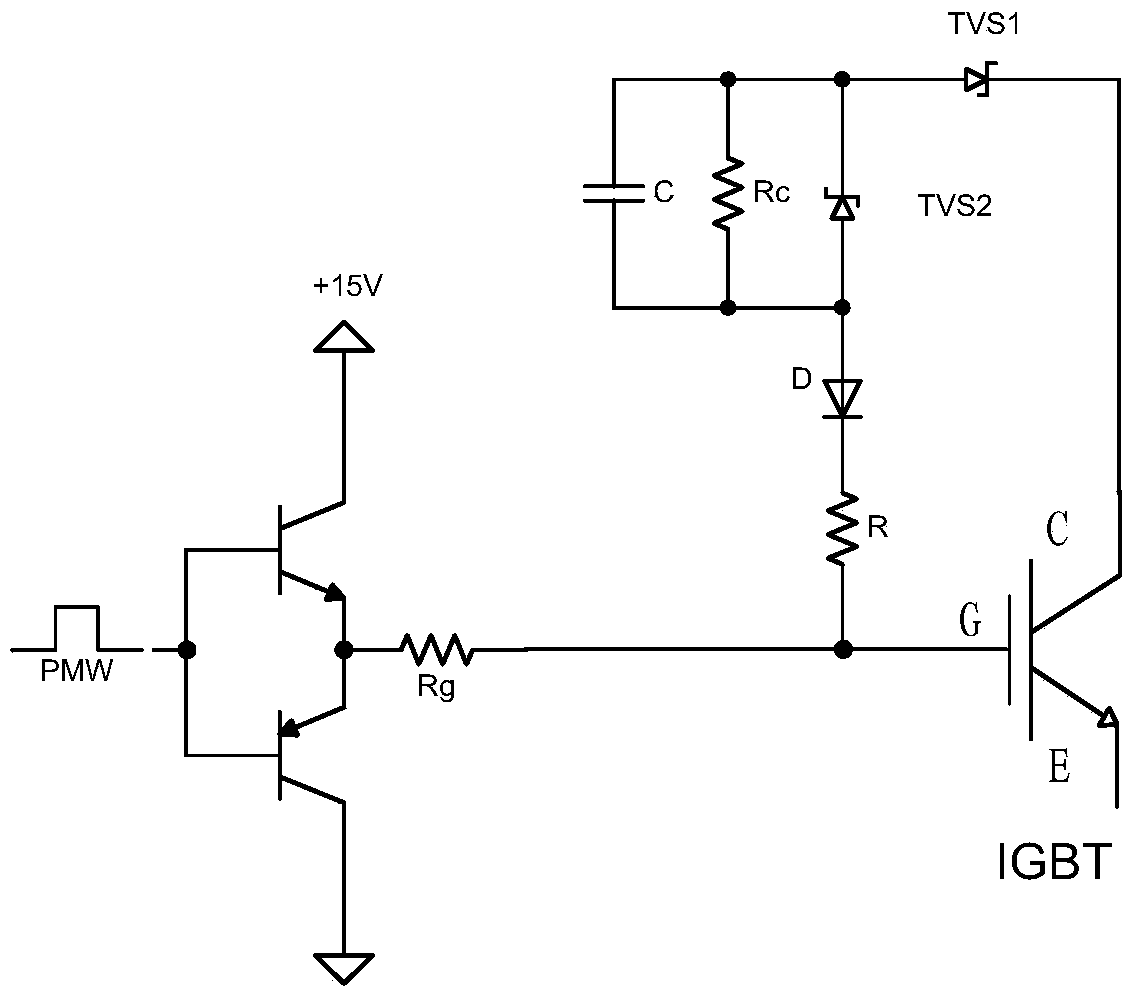

[0031] Such as Figure 4 As shown, an IGBT driving active clamping circuit is a part of the IGBT driving circuit, which is connected between the collector and the gate of the IGBT of the converter, and its specific structure can adopt the above technical solutions. The active clamping circuit has been successfully applied to the design of the IGBT drive circuit of the locomotive traction converter. In the 1800VDC-1300VAC two-level three-phase inverter, it is used to actively clamp the 3300V, 1200A IGBT Bit protection.

Embodiment approach

[0033] (1) in Figure 4 In the circuit shown, D1 to D30 are VISHAY's SMCJ series transient voltage suppression diodes, among which D1 to D22 are SMCJ100A, and D23 to D25 are SMCJ5A. They form a series combination of TVS1, U TVS1 The voltage threshold is 2215V; D26 to D29 are SMCJ150A, they form a series combination of TVS2, U TVS2 The voltage value is 600V, U TVS The voltage threshold is 2815V; D30 is SMCJ33A, which acts as a diode D to prevent the IGBT gate voltage from flowing to the collector.

[0034] (2) in Figure 4 In the circuit shown, C1 is a 22nF, 1000V metallized polypropylene film capacitor. The resistors R1 to R4 are 221k ohm metallized film resistors, and they are combined in series to form a discharge resistor Rc. The resistors R5 to R7 are metalized film resistors of 22 ohms, and they are combined in parallel to form a current limiting resistor R.

[0035] It can be seen that the embodiment of the present invention can perform device selection and parameter desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com