A double-layer gate dielectric thin film transistor with electrochromic properties

An electrochromic and dielectric thin film technology, which is applied in the direction of transistors, circuits, electrical components, etc., can solve the problems of poor uniformity of polysilicon thin film transistors, difficulty in providing driving current for light-emitting devices, and low carrier mobility, so as to improve the overall Performance, effect suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

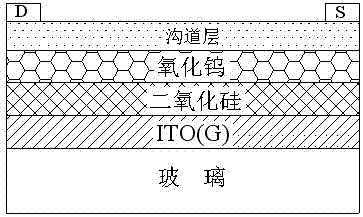

[0019] A preparation method of an electrochromic double-layer gate dielectric thin film transistor of the present invention comprises the following steps:

[0020] 1. Gate electrode preparation;

[0021] 2. Preparation of double-layer gate dielectric layer;

[0022] 3. Trench production;

[0023] 4. Masking, preparation of source (S) and drain (D).

Embodiment 1

[0025] 1. Clean the ITO glass substrate.

[0026] 2. The silicon dioxide proton conductor film was prepared by plasma chemical vapor deposition technology; the reaction gases used were silane and phosphine, and the concentration ratio was 9:1; argon gas was used for ignition; the oxygen flow rate used was 10 sccm; the radio frequency power used was 100W; The deposition pressure is 30 Pa; the temperature used is room temperature; and the thickness is 500 nm.

[0027] 3. The tungsten oxide film was prepared by sputtering. The target material used was a tungsten target with a concentration of 99.99%. Argon was used for ignition, the oxygen flow rate used was 14sccm, the radio frequency power was 100W, the deposition pressure was 0.1Pa, and the thickness was 300nm.

[0028] 4. Using magnetron sputtering technology, IZO is used as a target material, at room temperature, the reaction pressure is set to 1Pa, and the radio frequency power is set to 100W to prepare a channel layer with...

Embodiment 2

[0031] 1. Clean the common glass substrate.

[0032] 2. Using magnetron sputtering technology, using ITO as the target material, at room temperature, set the reaction pressure to 1Pa and the radio frequency power to 100W to prepare a gate electrode with a thickness of 80nm.

[0033] 3. The silicon dioxide proton conductor film was prepared by plasma chemical vapor deposition technology; the reaction gases used were silane and phosphine, the concentration ratio was 9:1; argon gas was used for ignition; the oxygen flow rate used was 10 sccm; the radio frequency power used was 200W; The deposition pressure is 10 Pa; the temperature used is room temperature; and the thickness is 1000 nm.

[0034] 4. The tungsten oxide film was prepared by sputtering. The target material used was a tungsten target with a concentration of 99.99%. Argon gas was used for ignition, the oxygen flow rate used was 14 sccm, the radio frequency power was 100W, the deposition pressure was 0.1Pa, and the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com