A ceramic metal halide lamp anti-aging high-viscosity printing ink

A technology of ceramic metal halide lamps and printing inks, applied in inks, household utensils, applications, etc., can solve the problems of poor imprinting effect and low adhesion, and achieve good printing effect, good ductility, and not easy to wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

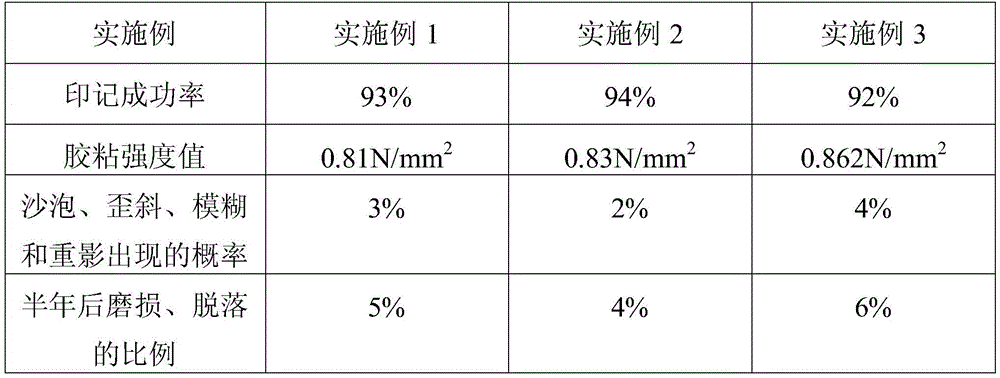

Examples

Embodiment 1

[0031] The anti-aging high-viscosity printing ink for ceramic metal halide lamps provided by the present invention has the following raw material composition and weight percentage ratio:

[0032] Silver oxide 7%, lead borate 5%, monohydric alcohol 8%, glycerin 6%, curing agent 1.5%, polyester resin 7%, dispersant 1.6%, defoamer 2.8%, wetting agent 1%, varnish 1%, ethyl acetate 7%, β-myrcene 2%, waste engine oil 3%, castor oil 6%, sodium silicate 3%, and the rest is water.

Embodiment 2

[0034] The anti-aging high-viscosity printing ink for ceramic metal halide lamps provided by the present invention has the following raw material composition and weight percentage ratio:

[0035] Silver oxide 9%, lead borate 8%, monohydric alcohol 9%, glycerin 9%, curing agent 2.5%, polyester resin 10%, dispersant 2.3%, defoamer 3%, wetting agent 1.5%, varnish 3%, ethyl acetate 10%, β-myrcene 4%, waste engine oil 5%, castor oil 8%, sodium silicate 8%, and the rest is water.

Embodiment 3

[0037] The anti-aging high-viscosity printing ink for ceramic metal halide lamps provided by the present invention has the following raw material composition and weight percentage ratio:

[0038] Silver oxide 13%, lead borate 12%, monohydric alcohol 10%, glycerin 11%, curing agent 3.5%, polyester resin 12%, dispersant 3.8%, defoamer 4.0%, wetting agent 1.9%, varnish 5%, ethyl acetate 13%, β-myrcene 6%, waste engine oil 7%, castor oil 9%, sodium silicate 11%, and the rest is water.

[0039] The preparation process of this product:

[0040] 1. Prepare silver oxide, lead borate and ethanol according to the above weight ratio and put them into the ball mill jar, then add agate balls of equal weight (the size to weight ratio of agate balls is 1:1), close the ball mill cover tightly and carry out ball milling. The time is not less than 60 hours, and the speed of the ball mill is not less than 200 rpm; after 60 hours of ball milling, add a certain amount of glycerin according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com