A tool system for online removal of tiny burrs on the working edge of a servo valve spool

A working edge and servo valve technology, which is applied in the direction of tools, manufacturing tools, and toolholder accessories for lathes. The burr is small, the removal is difficult, and the complete removal effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. The following embodiments are based on the technical solutions of the present invention, providing detailed implementation and specific operating procedures, but the scope of protection of the present invention is not limited to the following implementations example.

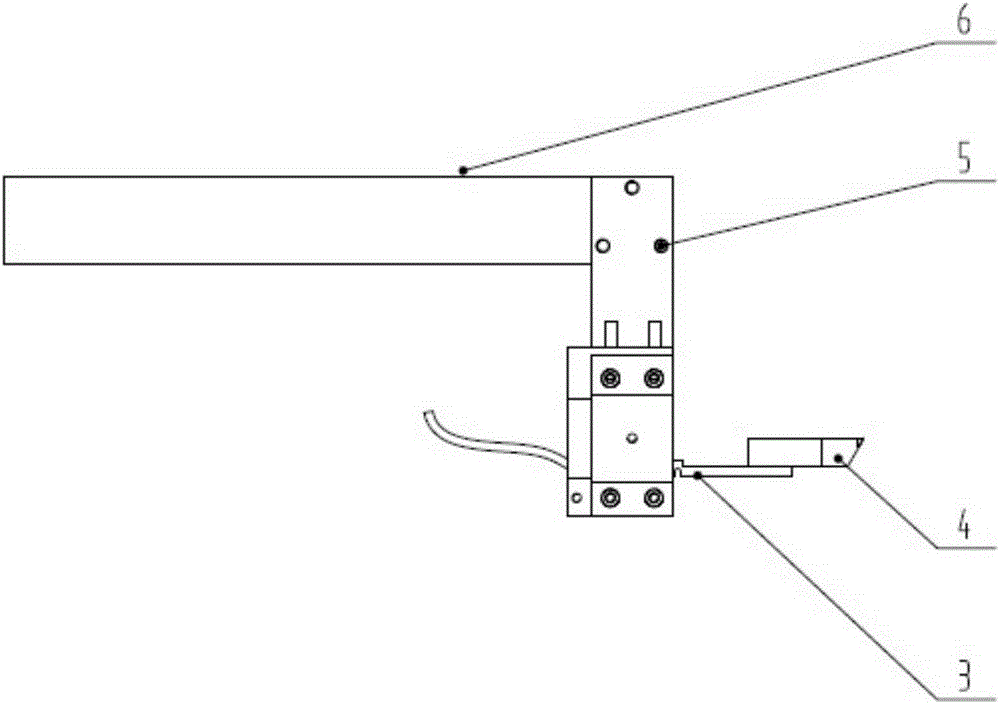

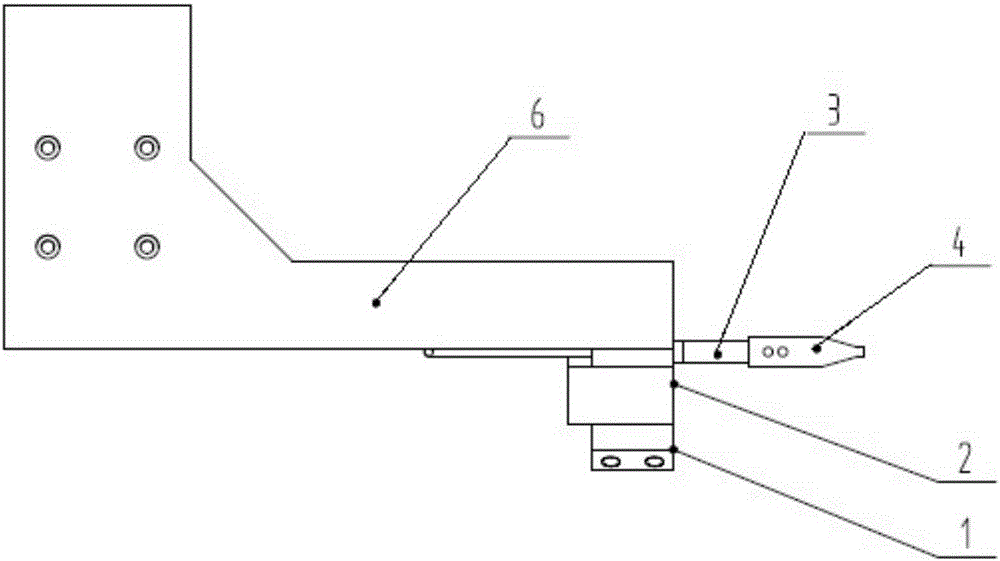

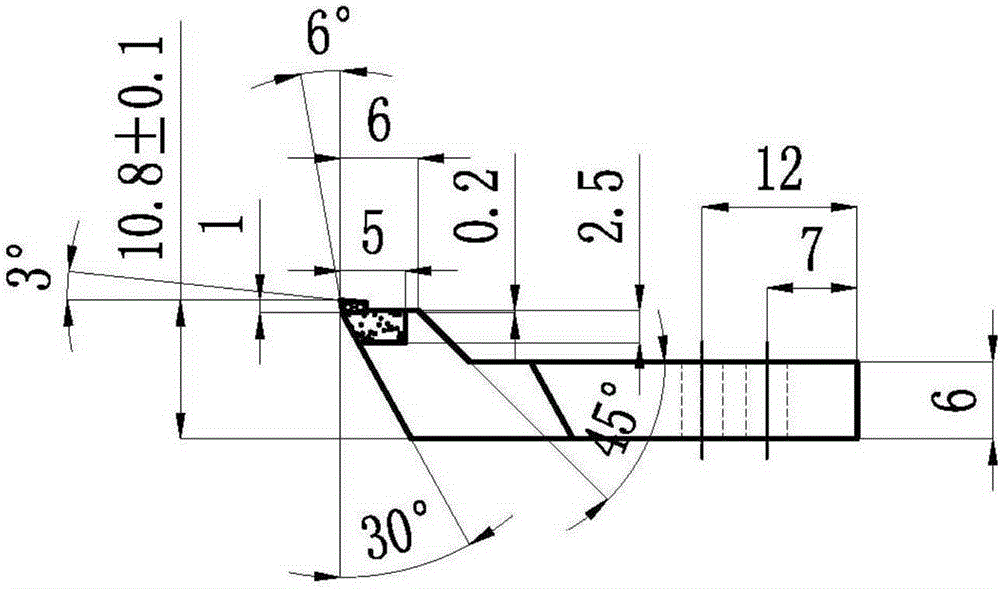

[0026] Please refer to figure 1 and figure 2 , the tool system for online removal of tiny burrs on the working edge of the servo valve core includes a turning tool 4, a cantilever force sensor 3, a sensor locking block 1, a clamp 2, an adjustment block 5 and a bridge plate 6. The servo valve valve The working edge of the core that needs to be deburred includes the outer circle, the left end face and the right end face (see Figure 5 ).

[0027] One end of the cantilever force sensor 3 is threaded to install the turning tool 4, and the other end is threaded to the clamp 2; the clamp 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com