Manufacturing method of high-quality P92 large-aperture thick-wall seamless steel pipe of ultra-supercritical unit

A technology of ultra-supercritical units and seamless steel pipes, applied in the field of heat-resistant steel pipe manufacturing, can solve problems such as increased manufacturing costs of boilers and power stations, prolonged construction periods of power plants, and expensive imported materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

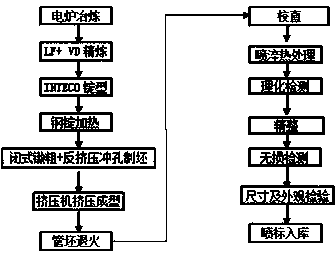

Method used

Image

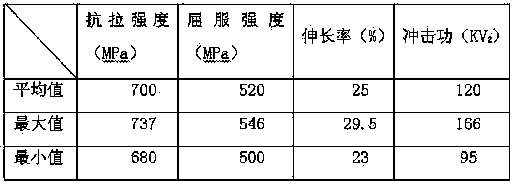

Examples

Embodiment 1

[0030] Production of P92 steel pipes with ID749×45х5000mm;

[0031] 1. Smelting

[0032] Control the chemical composition of P92 steel to the following table requirements:

[0033]

[0034] 2. The purity of steel

[0035] Vacuum carbon deoxidation combined with precipitation deoxidation and diffusion deoxidation process is adopted to control the total oxygen content in the steel to ≤15PPm, and the rating of various inclusions is ≤1.5 according to GB10561;

[0036] 1) Vacuum carbon deoxidation: before refining, first heat the temperature of molten steel to 1680-1700°C, and then use high-intensity argon blowing method under a vacuum degree of 67MPa, and the argon blowing intensity is controlled at 22-25Nm 3 / h, vacuum carbon deoxidation for 15-20 minutes;

[0037] 2) Precipitation deoxidation: After the vacuum carbon deoxidation is completed, add 0.4-0.6kg of silicon-aluminum-calcium-barium composite deoxidizer to each ton of steel in a vacuum state for deoxidation;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com