Method for purifying flue gas through activating persulfate by ozone, and apparatus thereof

A technology for activating persulfate and flue gas purification, which is applied to chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of initial investment and operation cost increase, and achieve simple and reliable equipment, no secondary pollution, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

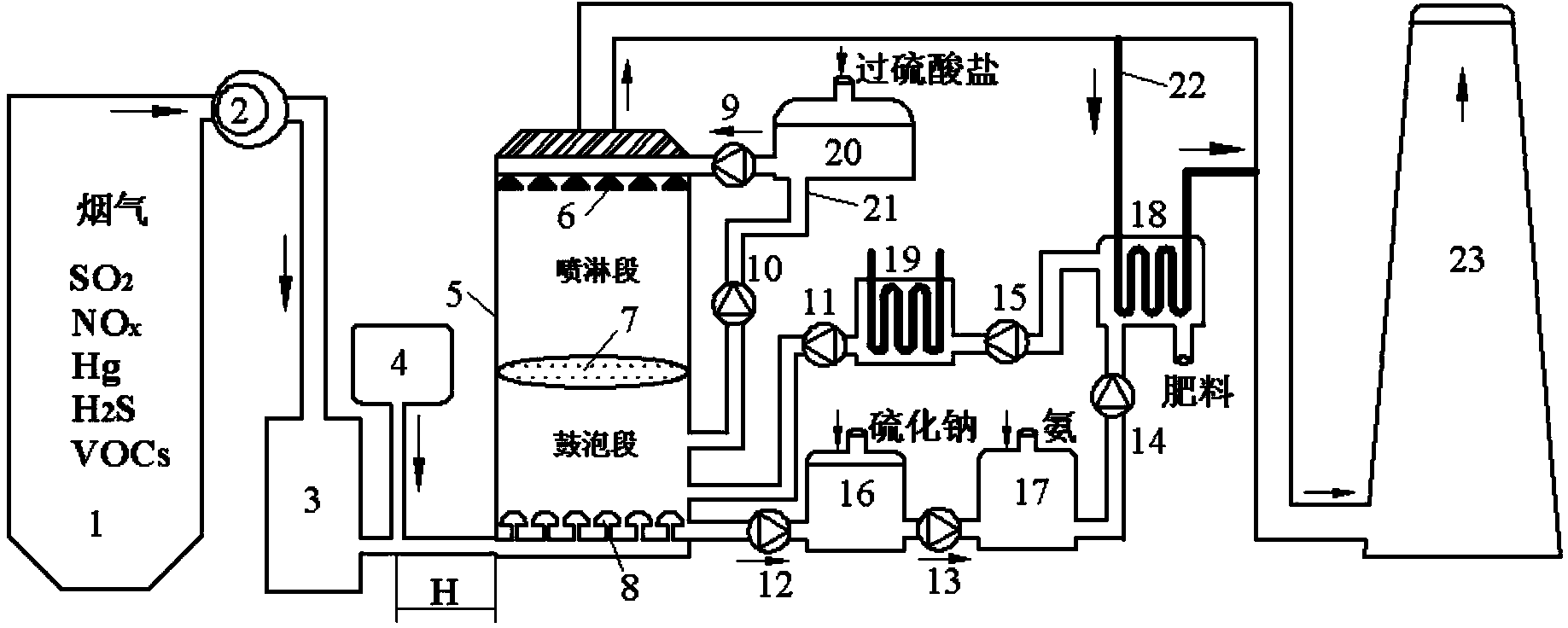

Method used

Image

Examples

Embodiment 1

[0051] Example 1. SO in flue gas 2 ﹑NO x ﹑ H 2 S﹑Hg 0 and VOCs concentrations are 2000ppm, 400ppm, 200ppm, 50ug / m 3 and 100mg / m 3 , the flue gas temperature is 25°C, the molar concentration of ammonium persulfate is 1.0mol / L, the ozone injection concentration is 100ppm, and the liquid-gas ratio is 5L / m 3 , The ozone injection distance is 50cm. SO in flue gas 2 ﹑NO x ﹑ H 2 S﹑Hg 0The simultaneous removal efficiencies of VOCs and VOCs were 100%, 60.9%, 100%, 78.8% and 38.2%, respectively.

Embodiment 2

[0052] Example 2. SO in flue gas 2 ﹑NO x ﹑Hg 0 and VOCs concentrations are 2000ppm, 400ppm, 200ppm, 50ug / m 3 and 100mg / m 3 , the flue gas temperature is 25°C, the molar concentration of potassium persulfate is 1.0mol / L, the ozone injection concentration is 100ppm, and the liquid-gas ratio is 10L / m 3 , The ozone injection distance is 50cm. SO in flue gas 2 ﹑NO x ﹑ H 2 S﹑Hg 0 The simultaneous removal efficiencies of VOCs and VOCs were 100%, 68.9%, 100%, 85.7% and 48.6%, respectively.

Embodiment 3

[0053] Example 3. SO in flue gas 2 ﹑NO x ﹑ H 2 S﹑Hg 0 and VOCs concentrations are 2000ppm, 400ppm, 200ppm, 50ug / m 3 and 50mg / m 3 , the flue gas temperature is 35°C, the molar concentration of sodium persulfate is 1.5mol / L, the ozone injection concentration is 300ppm, and the liquid-gas ratio is 25L / m 3 , The ozone injection distance is 100cm. SO in flue gas 2 ﹑NO x ﹑ H 2 S﹑Hg 0 The simultaneous removal efficiencies of VOCs and VOCs were 100%, 86.9%, 100%, 94.6% and 68.9%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com