Ball valve and combination method thereof

A combination method and ball valve technology, applied in valve details, valve device, valve housing structure, etc., can solve problems such as complex process, quality defects, and low reliability of valve cavity sealing, and achieve the effect of small heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described below in conjunction with specific embodiments.

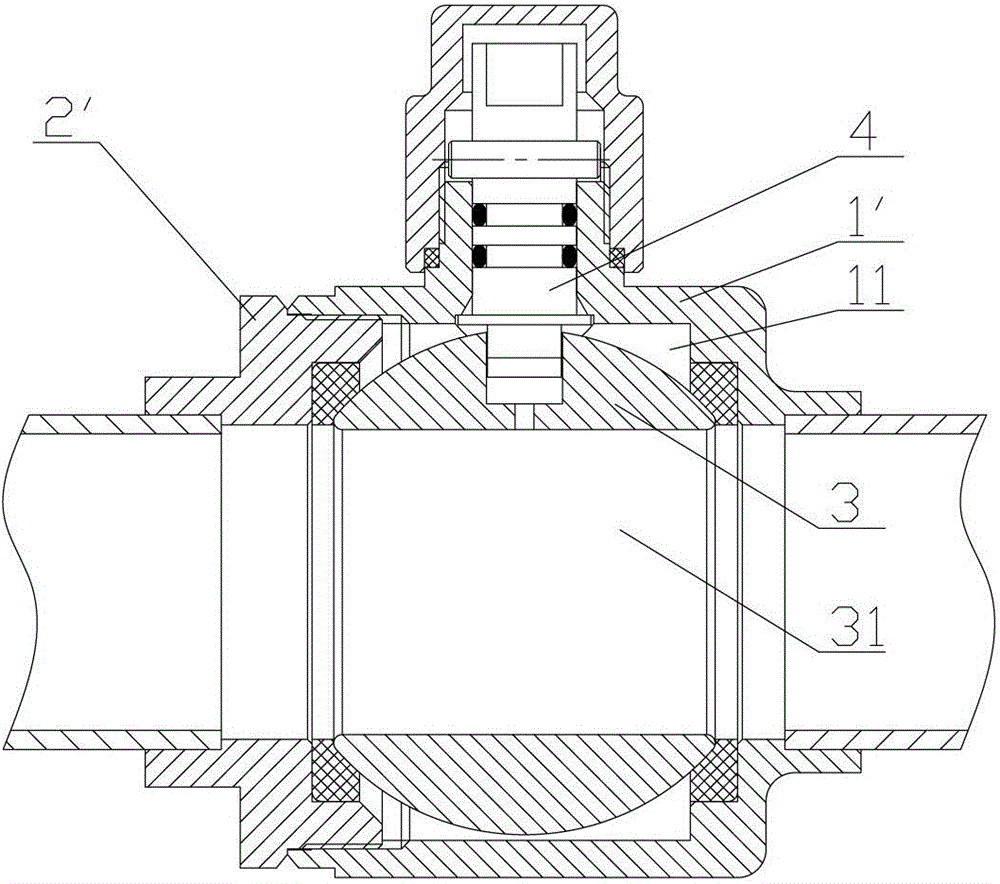

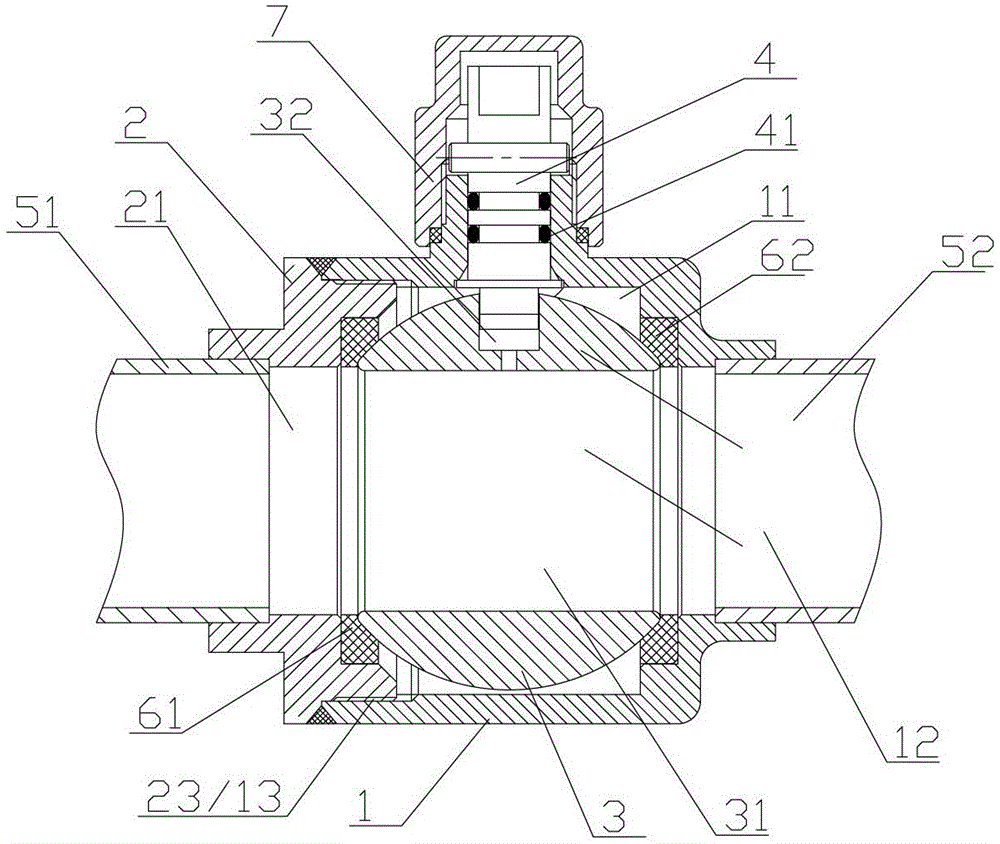

[0029] figure 2 It is a schematic structural diagram of a ball valve according to a specific embodiment of the present invention.

[0030] Such as figure 2 As shown, the ball valve of this specific structure includes a valve body 1 with a semi-open inner cavity 111, a second interface end 12 is formed at the bottom of the inner cavity 111, and a connecting pipe 52 is welded to the second interface end 12. A first threaded section 23 is provided on the outside of the semi-open inner cavity 111. A section of the valve seat 2 facing the valve body 1 is provided with a first threaded section 13. Through the cooperation of the screw mosquito section 13 and the threaded section 23, the valve seat 2 is connected to On the valve body 1, the inner cavity 111 between the valve seat 2 and the valve body 1 constitutes the valve cavity 11. The side of the valve seat fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com