Method for preparing natural gas from converter tail gas and production device using the method

A technology for converter tail gas and natural gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of limited application range, having to empty or light sky lanterns, etc., so as to avoid environmental pollution, realize resource utilization, and improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

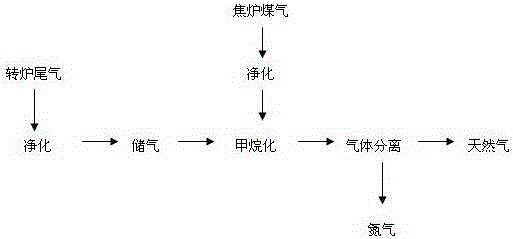

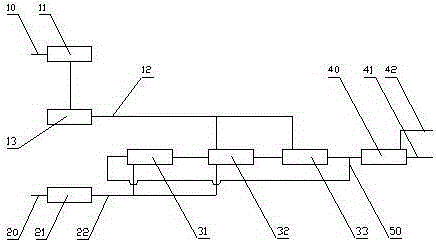

[0014] See figure 1 The present invention provides a method for preparing natural gas from converter tail gas. The converter tail gas and coke oven gas are used as raw material gas, and the converter tail gas is first stored in the converter tail gas storage container, and the converter tail gas and the converter tail gas are selected and / or adjusted. The ratio of coke oven gas is to send the converter tail gas and coke oven gas to the methanation unit. The hydrogen in the raw gas and the carbon monoxide and carbon dioxide in the raw gas are used for the methanation reaction to convert carbon monoxide and carbon dioxide. For methane, nitrogen is separated from the gas after methanation reaction to form natural gas composed of methane.

[0015] Since the content of the gas components involved in the reaction in the methanation device is very low, the effect on the methanation reaction is small, and usually can be ignored in the calculation, and only based on the methanation reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com