Insulative adhesive for preparing metallic and soft magnetic composite material and using method thereof

A composite material and metal soft magnetic technology, which is applied in adhesives, adhesive additives, and the magnetism of inorganic materials, can solve problems such as not being able to promote magnetic powder compression molding well, affecting the thermal stability of magnetic powder cores, and high thermal stability. Improve the coating effect, improve thermal stability and insulation effect, improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

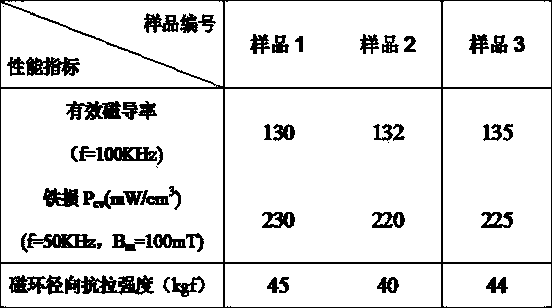

Embodiment 1

[0024] 1) Take an appropriate amount of pure iron powder and mix iron powders of different meshes. The iron powder powder with a particle size of -100 mesh to +200 mesh accounts for 10% of the total mass, and the iron powder powder of -200 mesh to +400 mesh It accounts for 60% of the total mass, and iron powder with a mesh size of 400 or more accounts for 30% of the total mass.

[0025] 2) Passivate the configured iron powder with phosphoric acid, stir and dry in a water bath at 60°C to obtain passivated iron powder. The mass of phosphoric acid accounts for 0.6% of the total mass of iron powder.

[0026] 3) First mix the prepared insulating adhesive with xylene, mix evenly, then heat and stir with passivated iron powder, mix evenly and then dry. The quality of the insulating bonding particles is 3% of the total mass of the magnetic powder, and the mass percentage of the composite insulating bonding particles is 40% silicone resin, 60% Al 2 o 3 Inorganic Nanodispersion.

[...

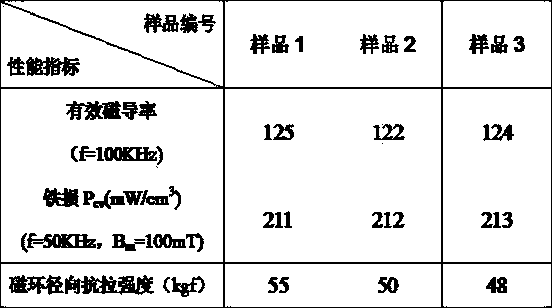

Embodiment 2

[0032] (1) Take an appropriate amount of sendust magnetic powder, mix sendust magnetic powder with different meshes, the particle size of the sendust magnetic powder can reach -100 mesh~+200 mesh, account for 30% of the total mass, and -200 mesh~+ 400 mesh sendust magnetic powder accounts for 40% of the total mass, and sendust magnetic powder above 400 mesh accounts for 30% of the total mass.

[0033] (2) Passivate the configured sendust magnetic powder with phosphoric acid, and the mass of phosphoric acid accounts for 0.6% of the total mass of sendust magnetic powder.

[0034](3) Mix the prepared insulating binder with xylene first, mix evenly, then heat and stir with passivated sendust magnetic powder, mix evenly and then dry. The quality of the insulating bonding particles is 1% of the total mass of the magnetic powder, and the mass percentage of the composite insulating bonding particles is 65% silicone resin, 35% SiO 2 Inorganic nanopowder.

[0035] (4) Add a release ag...

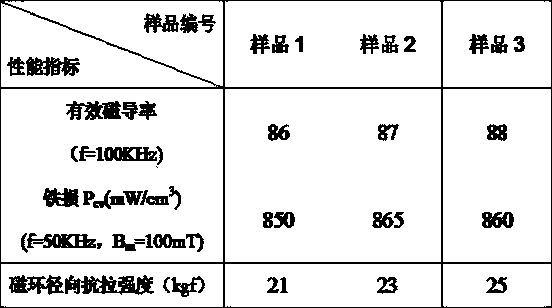

Embodiment 3

[0040] (1) Take an appropriate amount of iron-nickel-molybdenum magnetic powder (containing iron 17.0%, Mo2.0%, Cu1.0%, Al+Si<1.0%, the rest is Ni), and mix iron-nickel-molybdenum magnetic powder with different meshes The iron-nickel-molybdenum magnetic powder with a particle size of -100 mesh to +200 mesh accounts for 20% of the total mass, and the iron-nickel-molybdenum magnetic powder powder with a particle size of -200 mesh to +400 mesh accounts for 60% of the total mass. 25% of the total mass.

[0041] (2) Passivate the configured iron-nickel-molybdenum magnetic powder with chromic acid, and the mass of chromic acid accounts for 0.4% of the total mass of the iron-nickel-molybdenum magnetic powder.

[0042] (3) First mix the prepared insulating binder with xylene, mix evenly, then heat and stir with passivated iron-nickel-molybdenum magnetic powder, mix evenly and then dry. The quality of the insulating bonding particles is 2.5% of the total mass of the magnetic powder, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com