Preparation method of carbon-coated cuprous oxide and carbon-coated cuprous oxide

A technology of cuprous oxide and carbon coating, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the complex process of cuprous oxide, high cost, To solve the problem of low output, achieve the effect of good shape, large output and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

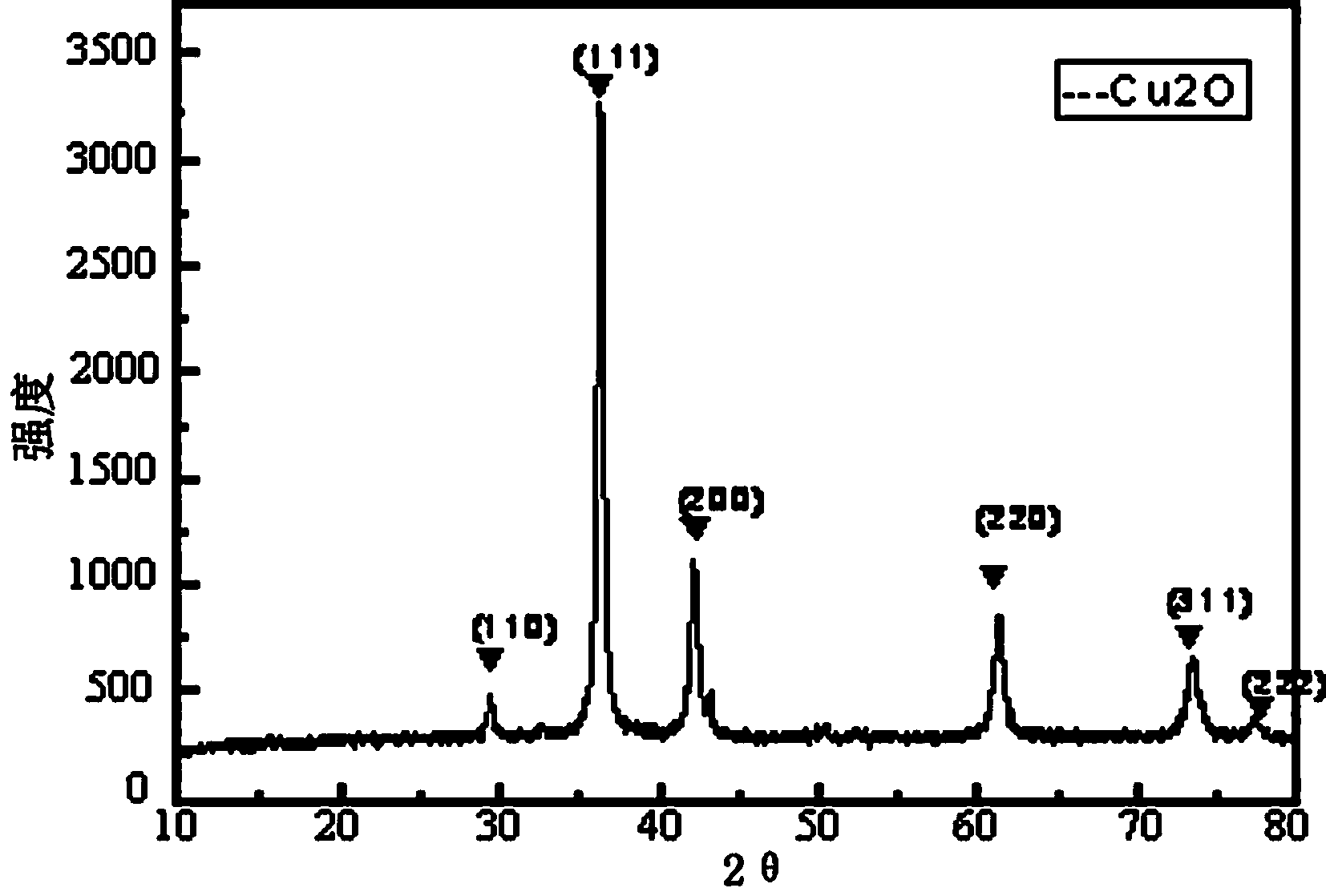

Embodiment 1

[0060] Stir 2g of homemade liquid acrylonitrile oligomer solution LPAN (molecular weight 4000) at 120°C for 120h to form a microcyclized LPAN solution, heat treat the microcyclized LPAN solution at 200~300°C for 8h, and form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid with trapezoidal structure, add 11.25g of copper oxide, 15-30ml of solvent, and use a planetary ball mill to grind the sample with a ball-to-material ratio of 15:1, 400rad / min ball mill for 10h, and produce After feeding, it was dried in an oven at 220°C for 3 hours to obtain a thermally oxidized precursor. Put the thermal oxidation precursor in a porcelain boat, and under the protection of an inert atmosphere, the gas flow rate is 150ml / min, calcined at 350°C for 4h, and cooled to room temperature to obtain a mixture of carbon-coated copper and carbon-coated cuprous oxide. The product structure is as follows Figure 1 to Figure 3 shown.

Embodiment 2

[0062] Stir 4g of polypyrrole (molecular weight 4000) at 120°C for 120h to form a micro-cyclized solution, heat-treat the micro-cyclized solution at 200-300°C for 8h to form thermally oxidized pyrrole oligomers with a certain ladder structure (OPly) solid, add 10g of copper oxide, 15-30ml of solvent, and ball mill the sample with a planetary ball mill, the ball-to-material ratio is 15:1, 400rad / min ball mill for 8h, after discharging, dry in an oven at 220°C for 3h to obtain the pre-thermal oxidation body. Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, the gas flow rate is 150ml / min, calcined at 300°C for 4h, and cooled to room temperature to obtain a mixture of a small amount of carbon-coated cuprous oxide and carbon-coated cupric oxide, the product structured as Figure 4 and Figure 5 shown.

Embodiment 3

[0064] Stir 10g of polythiophene (molecular weight 4000) at 120°C for 120h to form a microcyclized polythiophene solution, then heat-treat the microcyclized polythiophene solution at 200~300°C for 8h to form a thermally oxidized polythiophene solution with a certain trapezoidal structure. Thiophene oligomer (OPTh) solid, add 6.25g copper oxide, 15-30ml deionized water as a solvent, and use a planetary ball mill to grind the sample with a ball-to-material ratio of 15:1, 400rad / min ball mill for 8h, after discharging, 220 ℃ oven drying for 3h to obtain the thermal oxidation precursor. Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, with a gas flow rate of 150ml / min, calcinate at 250°C for 4h, and cool to room temperature to obtain a mixture of carbon-coated cuprous oxide and a small amount of carbon-coated cupric oxide, the product structured as Figure 6 and Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com