A preparation method of mixed-phase nano tio2 with different colors

A mixed-phase, nano-technology, applied in chemical instruments and methods, titanium oxide/hydroxide, physical/chemical process catalysts, etc., can solve the problems of complex steps, high natural cost, harsh experimental conditions, etc., and achieve the preparation process. Simple, low cost, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

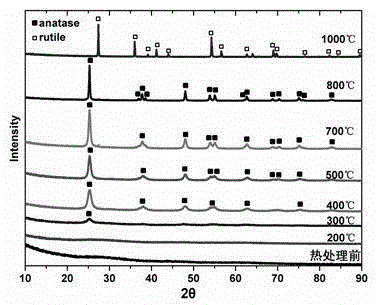

Embodiment 1

[0034] Under the condition of ice-water bath, add 12mL and 20mL prepared 8.0g / 100mL titanium sulfate solution and 4mol / L ammonia water to 100mL deionized water respectively, and magnetically stir the reaction system for 2 hours; centrifuge the stirred sol, and deionized water for solid precipitation Ultrasonic washing; take 100mL of the washed sol and dry it at 80°C to obtain white nano-TiO before heat treatment 2 solid( figure 1 ). The nano-TiO 2 Belongs to the amorphous state ( figure 2 ), no crystal structure was formed ( image 3 part a of ), the microstructure is TiO 6 octahedral aggregates, according to the quantum size effect, the TiO 2 There are only discrete energy levels, and there is no quasi-continuous band structure, so the band gap is very large ( Figure 7 ). Its specific surface area is as high as 328.55m 2 / g, so it has a strong adsorption effect on organic matter in the solution, but due to poor crystallinity and large band gap, it has almost no phot...

Embodiment 2

[0036] Under the condition of ice-water bath, add 12mL and 20mL prepared 8.0g / 100mL titanium sulfate solution and 4mol / L ammonia water to 100mL deionized water respectively, and magnetically stir the reaction system for 2 hours; centrifuge the stirred sol, and deionized water for solid precipitation Ultrasonic washing; take 100mL of the washed sol and dry it at 80°C to obtain white nano-TiO 2 solid, and then heat-treated at 200 °C for 3 h to obtain brown mixed-phase nano-TiO 2 ( figure 1 ). The nano-TiO 2 Most are amorphous ( figure 2 ), while anatase phase crystals began to nucleate, with an average particle size of 1.44nm ( image 3 part b), the specific surface area is up to 281.88m 2 / g. The TiO 2 has the highest and continuous visible light absorption ( Figure 5 ), and thus has the greatest degree of band bending, resulting in the narrowest bandgap ( Figure 7 ). The product also has a certain adsorption capacity, but due to poor crystallinity and low photocat...

Embodiment 3

[0038] Under the condition of ice-water bath, add 12mL and 20mL prepared 8.0g / 100mL titanium sulfate solution and 4mol / L ammonia water to 100mL deionized water respectively, and magnetically stir the reaction system for 2 hours; centrifuge the stirred sol, and deionized water for solid precipitation Ultrasonic washing; take 100mL of the washed sol and dry it at 80°C to obtain white nano-TiO 2 solid, and then heat-treated at 400 °C for 3 h to obtain yellow nano-TiO 2 ( figure 1 ). The nano-TiO 2 Belongs to anatase and amorphous mixed phase ( figure 2 ), the anatase phase crystals gradually grew up, and the average particle size increased to 8.90nm ( image 3 part c), the specific surface area is 161.18m 2 / g. The TiO 2 A bump appears in the visible light absorption spectrum ( Figure 5 ), indicating that it has an interband energy level ( Figure 7 ), which is also the main reason for the narrowing of its forbidden band width. The adsorption capacity of this product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com