A virus inactivator and its production process

A virus inactivation and anti-rust agent technology, applied in the direction of disinfectant, biocide, animal repellent, etc., can solve the problems that disinfectants cannot kill viruses, and the effect of killing viruses is not ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

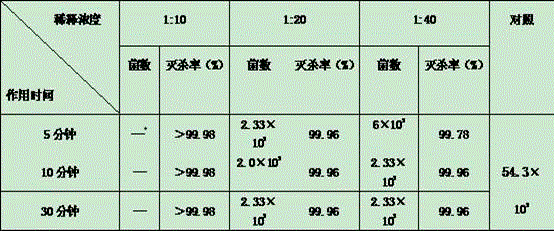

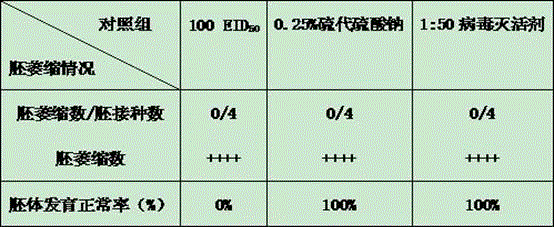

Image

Examples

Embodiment 1

[0015] A virus inactivator, comprising trisodium phosphate, sodium dihydrogen phosphate, sodium carbonate, sodium hydroxide, sodium hypochlorite, sodium silicate, sodium molybdate, deionized water or distilled water, wherein the above-mentioned components are respectively by weight percentage: phosphoric acid Three sodium: 4%, sodium dihydrogen phosphate: 0.5%, sodium carbonate: 0.2%, sodium hydroxide: 1%, sodium hypochlorite: 0.5% based on available chlorine, sodium silicate: 2%, sodium molybdate: 0.7%, The rest is deionized or distilled water.

Embodiment 2

[0017] A virus inactivator, comprising trisodium phosphate, sodium dihydrogen phosphate, sodium carbonate, sodium hydroxide, sodium hypochlorite, sodium silicate, sodium molybdate, deionized water or distilled water, wherein the above-mentioned components are respectively by weight percentage: phosphoric acid Three sodium: 6%, sodium dihydrogen phosphate: 1%, sodium carbonate: 0.3%, sodium hydroxide: 1%, sodium hypochlorite: 0.8% based on available chlorine, sodium silicate: 2.5%, sodium molybdate: 1%, The rest is deionized or distilled water.

Embodiment 3

[0019] A virus inactivator, comprising trisodium phosphate, sodium dihydrogen phosphate, sodium carbonate, sodium hydroxide, sodium hypochlorite, sodium silicate, sodium molybdate, deionized water or distilled water, wherein the above-mentioned components are respectively by weight percentage: phosphoric acid Three sodium: 6.3%, sodium dihydrogen phosphate: 1%, sodium carbonate: 0.3%, sodium hydroxide: 1%, sodium hypochlorite: 1% based on available chlorine, sodium silicate: 2.5%, sodium molybdate: 1.1%, The rest is deionized or distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com