Water-based wood paint modified by vegetable oil and preparation method of water-based wood paint

A water-based wood paint and vegetable oil modification technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of insufficient comprehensive performance and achieve rich product types, easy access and purchase, and excellent surface enrichment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

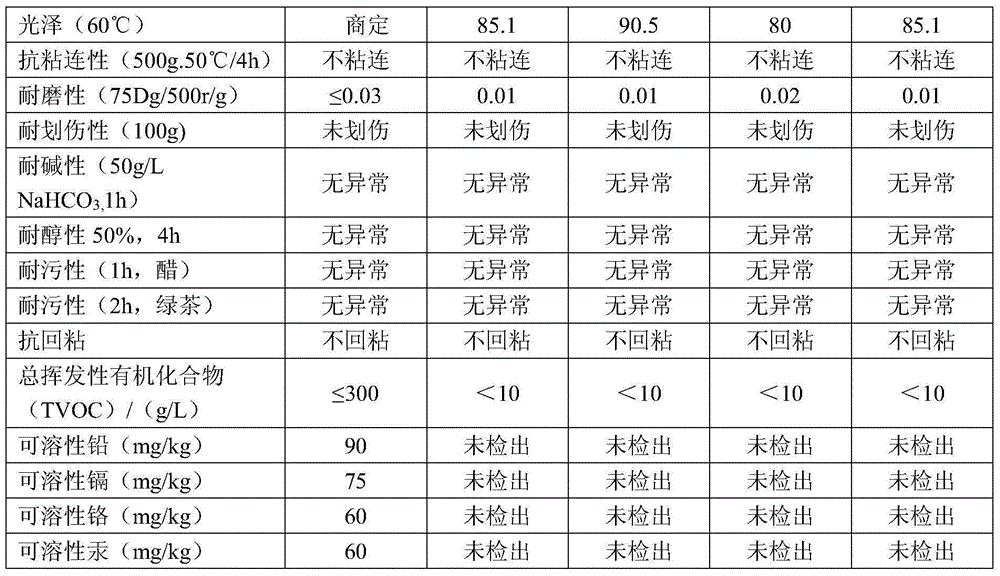

Examples

Embodiment 1

[0050] Prepare the water-based black wood finish of vegetable oil modification by the formula weight part of table 3, comprise the following steps:

[0051] a) Prepare raw materials according to the weight parts set by the formula, put water, wetting and dispersing agent, black paste ColanylBlackN, and defoamer into the container and stir at a high speed of 1200-1400 rpm, stir for 15 minutes, and then reduce the speed to 1000 rpm , while stirring, add aliphatic modified polyurethane dispersion and hardening resin, after stirring for 10 minutes, add antifreeze, wax emulsion, plant-based composite nano-bactericidal powder and stir for 5 minutes, reduce the speed to 600 rpm, add pH adjustment Adjust the pH value to 8 with the agent, and add the thickener to adjust the viscosity required by the customer.

[0052] b) Detection-filter-package-sample retention.

Embodiment 2

[0054] The adjustment of this embodiment formula proportion is shown in Table 3 for details, and wherein pigment adopts titanium dioxide, is specifically R-996; for 30 minutes.

Embodiment 3

[0056] The adjustment of this embodiment formula proportion is shown in Table 3 for details, and wherein pigment adopts medium yellow paste, is specifically ColanylYellow2GXD; 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com