A kind of plastic molding agent and its preparation method and application

A reinforcing agent and monomer technology, which is applied in the field of water-absorbing reinforcing materials for plastic molding and its preparation, can solve the problems of reducing the tensile and impact properties of composite materials, and greatly affecting the mechanical properties of composite materials, so as to improve specific performance and avoid The effect of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

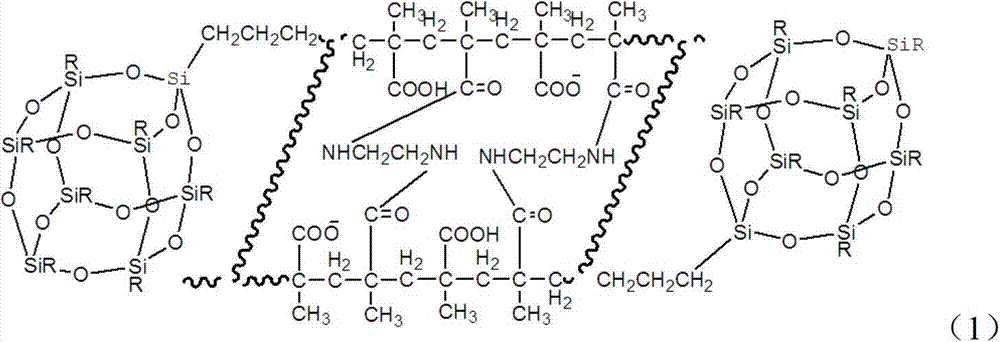

Method used

Image

Examples

Embodiment 1

[0048] (1) Put cyclopentyltrimethoxysilane, water and sodium hydroxide in a molar ratio of 7:8:2 into a three-necked flask filled with tetrahydrofuran, stir at 70°C for 5 hours, and then Stir for 15 hours, and finally filter to obtain a white solid powder, put it in a vacuum oven at 60°C and dry at constant temperature for 24 hours to obtain the product (I).

[0049] (2) Under a nitrogen atmosphere, react the product (I) with γ-chloropropyltrichlorosilane at a molar ratio of 1:1, first dissolve the product (I) in anhydrous tetrahydrofuran, and then dissolve the γ-chloropropyl trichlorosilane Propyltrichlorosilane was quickly added to the reaction system, reacted in an ice-water bath for 3 hours, and then stirred at room temperature for 3 hours. The solvent was removed with a rotary evaporator and the product precipitated on the bottle wall was dissolved with chloroform. The organic layer was retained after shaking washing with distilled water in a separatory funnel, and washe...

Embodiment 2

[0056] (1) Put cyclopentyltrimethoxysilane, water and sodium hydroxide in a molar ratio of 7:8:3 into a three-necked flask filled with tetrahydrofuran, stir at 70°C for 5h, and then Stir for 15 hours, and finally filter to obtain a white solid powder, put it in a vacuum oven at 60°C and dry at constant temperature for 24 hours to obtain the product (I).

[0057] (2) Under a nitrogen atmosphere, the product (I) reacts with γ-chloropropyltrichlorosilane at a molar ratio of 1:1.1. First, the product (I) is dissolved in anhydrous tetrahydrofuran, and then the γ-chloro Propyltrichlorosilane was quickly added to the reaction system, reacted in an ice-water bath for 3 hours, and then stirred at room temperature for 3 hours. The solvent was removed with a rotary evaporator and the product precipitated on the bottle wall was dissolved with chloroform. The organic layer was retained after shaking washing with distilled water in a separatory funnel, and washed with anhydrous MgSO 4 Rem...

Embodiment 3

[0063] (1) Put cyclopentyltrimethoxysilane, water and sodium hydroxide in a molar ratio of 7:8:4 into a three-necked flask filled with tetrahydrofuran, stir at 70°C for 5 hours, and then Stir for 15 hours, and finally filter to obtain a white solid powder, put it in a vacuum oven at 60°C and dry at constant temperature for 24 hours to obtain the product (I).

[0064] (2) Under a nitrogen atmosphere, the product (I) reacts with γ-chloropropyltrichlorosilane at a molar ratio of 1:1.2. First, the product (I) is dissolved in anhydrous tetrahydrofuran, and then the γ-chloropropyl Trichlorosilane was quickly added to the reaction system, reacted in an ice-water bath for 3 hours, and then stirred at room temperature for 3 hours. The solvent was removed with a rotary evaporator and the product precipitated on the bottle wall was dissolved with chloroform. The organic layer was retained after shaking washing with distilled water in a separatory funnel, and washed with anhydrous MgSO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com