Stainless steel hydrogen permeation barrier composite membrane and preparation method thereof

A composite membrane and stainless steel technology, applied in the field of materials, can solve the problems of hindering hydrogen permeation membrane layer, less patents, less membrane component content and less preparation methods, etc., achieves great application value, easy realization, and simple preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

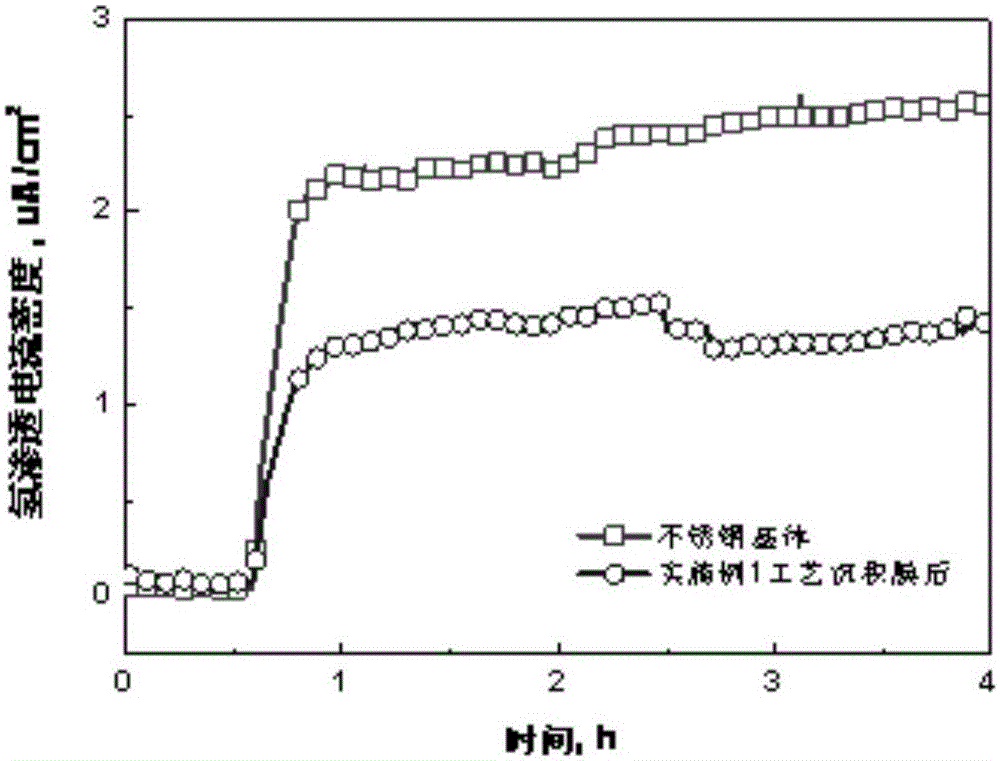

[0028] Example 1: 2205 stainless steel is used as the substrate, and a CrAlMoN hydrogen permeation barrier film is deposited on the surface.

[0029] The specific production process is as follows:

[0030] A. Clean the surface of the stainless steel substrate;

[0031] B. Then when the vacuum degree is greater than 10 -6 Under the condition of Pa, using the multi-target magnetron sputtering method, a Cr target, an Al target, and a Mo target are used, and the rotation speed of the base is controlled at 0.5 revolutions per minute, and a composite film is deposited on the rotating stainless steel substrate at one time. The target power is 150W for Cr target, 300W for Al target and 150W for Mo target. Ar 2 is the sputtering gas, Ar 2 The flow rate is 200cm 3 / s, Ar 2 The partial pressure is 0.5Pa, and the reaction gas is N 2 . After testing, the weight percentage content of each component of the composite film is 0.4% of Cr, 3.6% of Al, 0.5% of Mo, and the rest is N, and t...

Embodiment 2

[0037] Example 2: 2205 stainless steel is used as the substrate, and a CrAlMoN hydrogen permeation barrier film is deposited on the surface.

[0038] The specific production process is as follows:

[0039] A. Clean the surface of the stainless steel substrate

[0040] B. Then when the vacuum degree is greater than 10 -6 Under the condition of Pa, using the multi-target magnetron sputtering method, a Cr target, an Al target, and a Mo target are used, and the rotation speed of the base is controlled at 1 revolution per minute, and a composite film is deposited on the rotating stainless steel substrate at one time. The target power is 180W for Cr target, 400W for Al target and 160W for Mo target. Ar 2 is the sputtering gas, Ar 2 The flow rate is 250cm 3 / s, Ar 2 The partial pressure is 0.9Pa, and the reaction gas is N 2 . The thickness of the prepared CrAlMoN film is 8um. After testing, the weight percentage content of each component of the composite film is Cr0.8%, Al6.5...

Embodiment 3

[0046] Example 3: 2205 stainless steel is used as the substrate, and a CrAlMoN hydrogen permeation barrier film is deposited on the surface.

[0047] The specific production process is as follows:

[0048] A. Clean the surface of the stainless steel substrate

[0049] B. Then when the vacuum degree is greater than 10 -6 Under the condition of Pa, using the multi-target magnetron sputtering method, a Cr target, an Al target, and a Mo target are used, and the rotation speed of the base is controlled at 2 revolutions per minute, and a composite film is deposited on the rotating stainless steel substrate at one time. The target power is 200W for Cr target, 500W for Al target and 200W for Mo target. Ar 2 is the sputtering gas, Ar 2 The flow rate is 300cm 3 / s, Ar 2 The partial pressure is 1.8Pa, and the reaction gas is N 2 . After testing, the thickness of the prepared CrAlMoN film is 5um, and the weight percentage content of each component of the composite film is Cr0.8%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com