Flexible ultrathin graphite bipolar plate and preparation method thereof

A bipolar plate, ultra-thin technology, applied in the direction of fuel cells, electrochemical generators, electrical components, etc., can solve the problems of unsatisfactory compressive strength, graphite bipolar plate flow channel, low precision, high residual rate, etc. Achieve the effect of reducing hydrogen permeability, avoiding hydrogen leakage and increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] An embodiment of the present invention provides a method for preparing a flexible ultra-thin graphite bipolar plate, including:

[0020] Graphite powder material is provided, and described graphite powder material comprises expanded graphite, carbon fiber, carbon nanotube and low-viscosity liquid binder;

[0021] Provide a carbon nanotube film, and use physical or chemical methods to roughen the surface of the carbon nanotube film;

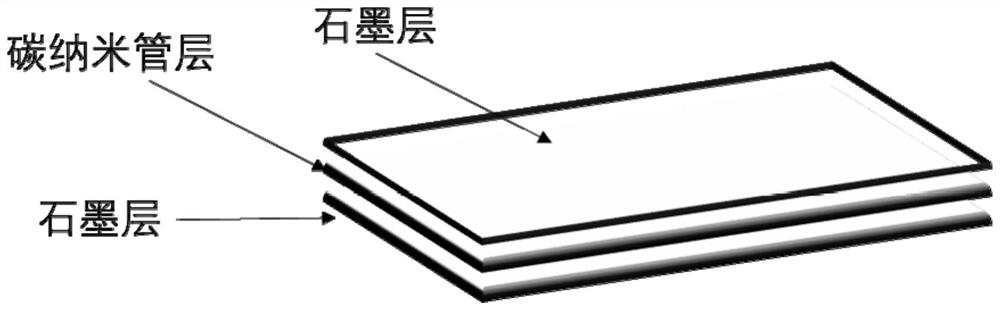

[0022] Graphite powder material layers formed by the graphite powder material are arranged on both sides of the carbon nanotube film, and the two layers of the graphite powder material layer are combined with the carbon nanotube film by hot pressing to form a flexible ultra-thin film. Graphite bipolar plates.

[0023] Further, the pressure of hot pressing is 5-22MPa, the temperature is 100-250°C, and the time is 1-30min.

[0024] Further, the preparation method of the flexible ultra-thin graphite bipolar plate also includes: calcining the...

Embodiment 1

[0048] Embodiment 1 Preparation of flexible ultra-thin graphite bipolar plate

[0049] 1) Mix 70 parts of expanded graphite, 20 parts of carbon fiber, and 10 parts of carbon nanotubes, then add 10 parts of liquid special phenolic resin binder, mix and stir for 3 hours to make the powder wet;

[0050] 2) Bake the mixed wet powder at 50°C for 2 hours to remove a small amount of liquid solvent;

[0051] 3) heat the carbon nanotubes in a hydrogen peroxide-sulfuric acid solution at 90°C for 2 hours, so that the surface of the carbon nanotubes is hydroxylated, and this treatment can increase the binding force between the carbon nanotubes and the surface of the graphite powder;

[0052] 4) Put an appropriate amount of the powder material in step 2) on the surface of the mold, press lightly to flatten it, and then spread a layer of carbon nanotube film, and then add an appropriate amount of powder material in step 2) on the nanotube film , using a mold for hot pressing, the hot press...

Embodiment 2

[0055] Embodiment 2 Preparation of flexible ultra-thin graphite bipolar plate

[0056] 1) Mix 80 parts of expanded graphite, 10 parts of carbon fiber, and 10 parts of carbon nanotubes, then add 10 parts of liquid special melamine resin binder, mix and stir for 4 hours to make the powder wet.

[0057] 2) Bake the above mixed wet powder at 60° C. for 1 hour to remove a small amount of liquid solvent.

[0058] 3) Use a laser marking machine to punch holes on the surface of the carbon nanotubes to roughen the surface, which is used to increase the bonding force between the carbon nanotubes and the surface of the graphite powder.

[0059] 4) Put an appropriate amount of the powder material in step 2) on the surface of the mold, press lightly to flatten it, and then spread a layer of carbon nanotube film, and then add an appropriate amount of powder material in step 2) on the nanotube film , using a mold for hot pressing, the hot pressing pressure is 22MPa, the hot pressing tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com