Integrated refining system and process using oil shale retorting gas to produce hydrogen and upgrade

A technology of oil shale and retort gas, which is applied in the petroleum industry, special form of retort, hydrogen, etc., can solve the problems of low utilization of clastic shale, lower process economic benefits, and low calorific value of residual gas, so as to improve Resource utilization, reduce production costs, and solve the effects of underutilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The specific implementation of the integrated refining process for hydrogen production and upgrading of oil shale dry distillation gas in this embodiment is as follows:

[0055] The flow rate of raw material shale entering the process of the present invention is 300t / h, of which 225t / h enters the dry distillation furnace, and the flow rate of clastic shale is 75t / h. The circulation rate of CaO is 44.4t / h, and the flow rate of steam is 38.02t / h. The industrial analysis and elemental analysis of oil shale are shown in Table 1.

[0056] Table 1 Elemental analysis of industrial analysis of oil shale

[0057]

[0058] The ar in the table indicates that the base is received.

[0059] The flow chart of the integrated refining process for hydrogen production and upgrading of oil shale retort gas is as follows: figure 2 and image 3 Shown:

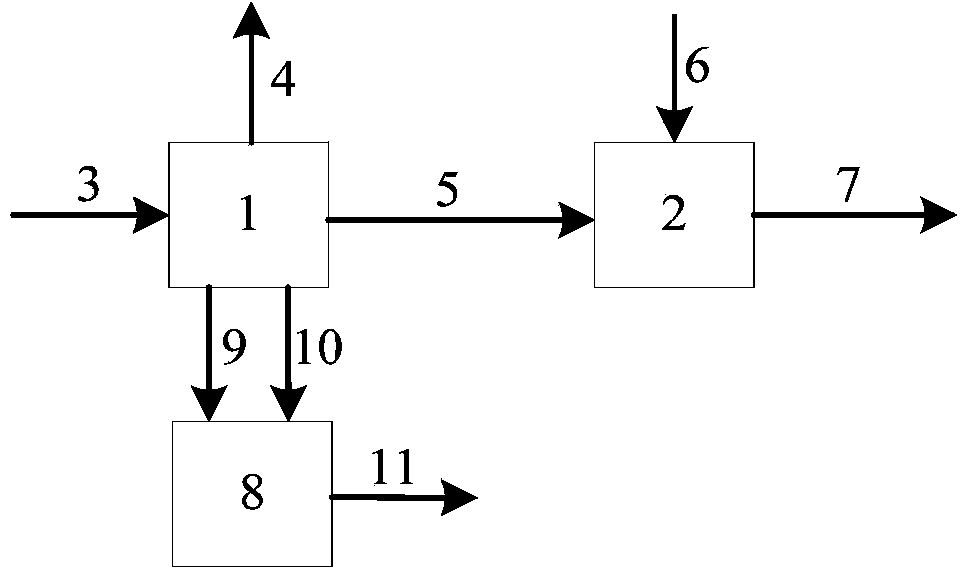

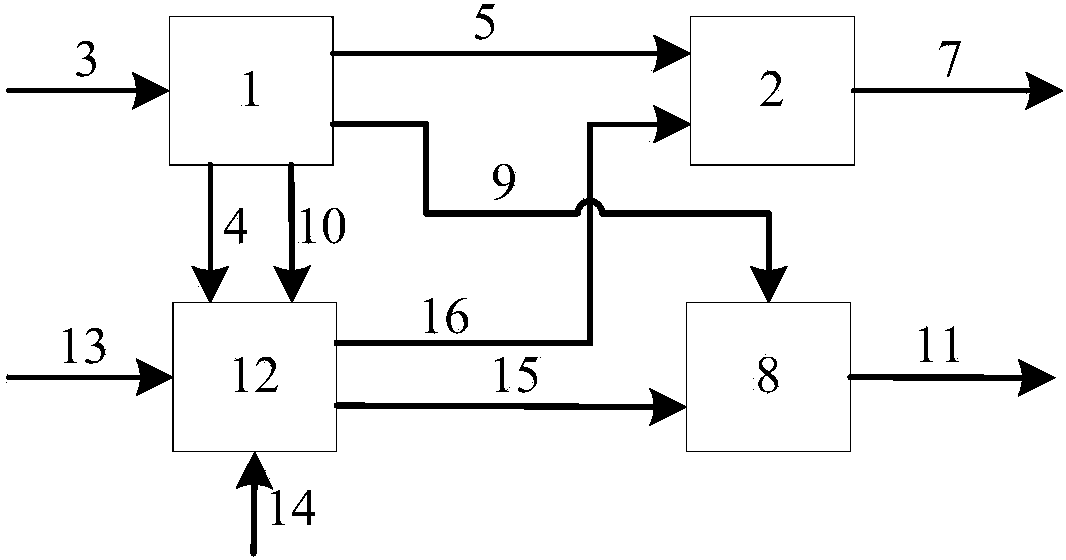

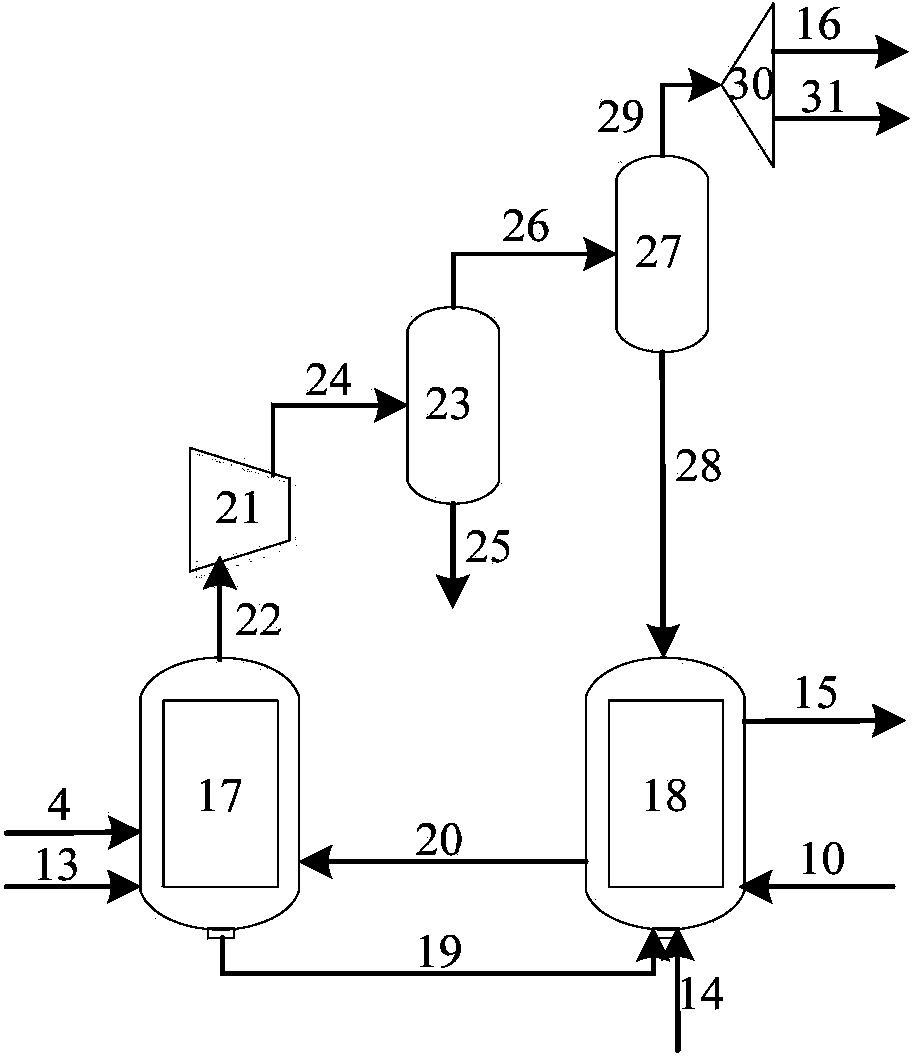

[0060] The integrated refining system includes an oil shale dry distillation unit 1, a shale oil hydro-upgrading unit 2, a methane...

Embodiment 2

[0070] The specific implementation of the integrated refining process for hydrogen production and upgrading of oil shale dry distillation gas in this embodiment is as follows:

[0071] The flow rate of raw material shale entering the process of the present invention is 400t / h, of which 300t / h enters the carbonization furnace, and the flow rate of clastic shale is 100t / h. The circulation rate of CaO is 60.5t / h, and the flow rate of steam is 55.75t / h. The industrial analysis and elemental analysis of oil shale are shown in Table 2.

[0072] Table 2 Elemental analysis of industrial analysis of oil shale

[0073]

[0074]

[0075] The ar in the table indicates that the base is received.

[0076] The flow chart of the integrated refining process for hydrogen production and upgrading of oil shale retort gas is as follows: figure 2 and image 3 Shown:

[0077] The integrated refining system includes an oil shale dry distillation unit 1, a shale oil hydro-upgrading unit 2, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com