A composite screw feeder made of high wear-resistant polyurethane material

A technology of polyurethane material and screw feeder, which is applied in the field of lifting equipment and short-distance material transportation, can solve the problems of fast wear and tear of auger shells and auger pieces, difficult maintenance and replacement, and short service life of accessories, so as to achieve product quality Stability, easy maintenance and replacement, and the effect of improving the life of equipment accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

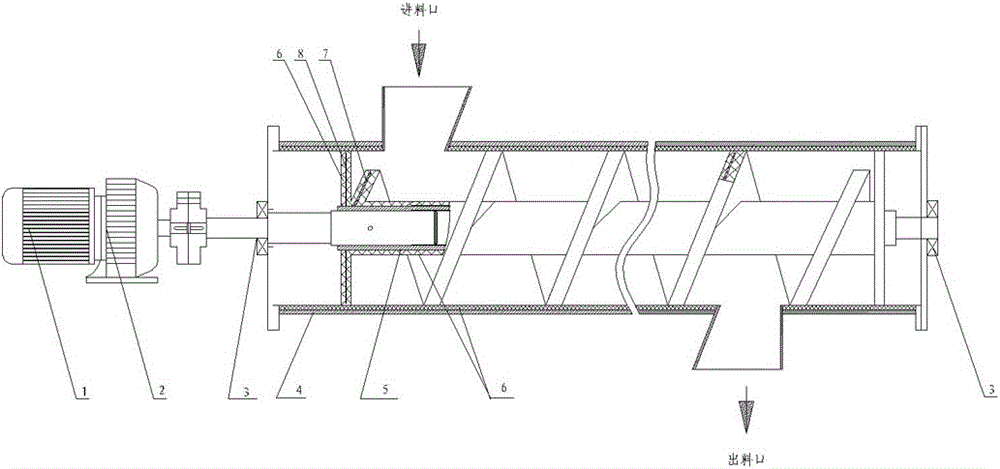

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] As shown in the accompanying drawings, the present invention includes a motor 1, a reduction box 2, a bearing and a support 3, an auger metal casing 4, a screw shaft 5, a screw blade 7, and the like. The motor 1 and the reduction box 2 are conventional standard products, and the metal casing 4 of the auger, the screw shaft 5 and the screw blade 7 are all metal products. A material blocking plate 8 is designed at the front of the feed end of the screw shaft 5 and the rear of the discharge end, which largely avoids the accumulation of materials at the bearings, greatly reduces the wear of the materials on the bearings, and improves the life of equipment accessories. .

[0013] The metal casing 4 of the auger is lined with a polyurethane lining 6, the screw shaft 5 is lined with a polyurethane lining 6, and both sides of the spiral piece 7 and the retaining plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com