Drawing oil containing lecithin

A wire drawing oil and lecithin technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as difficult to meet the requirements of wire drawing and drawing process, unsatisfactory lubricating effect, difficult cleaning and chip removal, etc., to achieve Stable emulsifying effect, easy cleaning, excellent high temperature lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

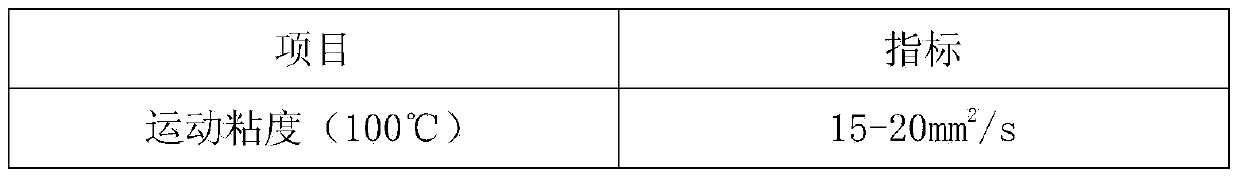

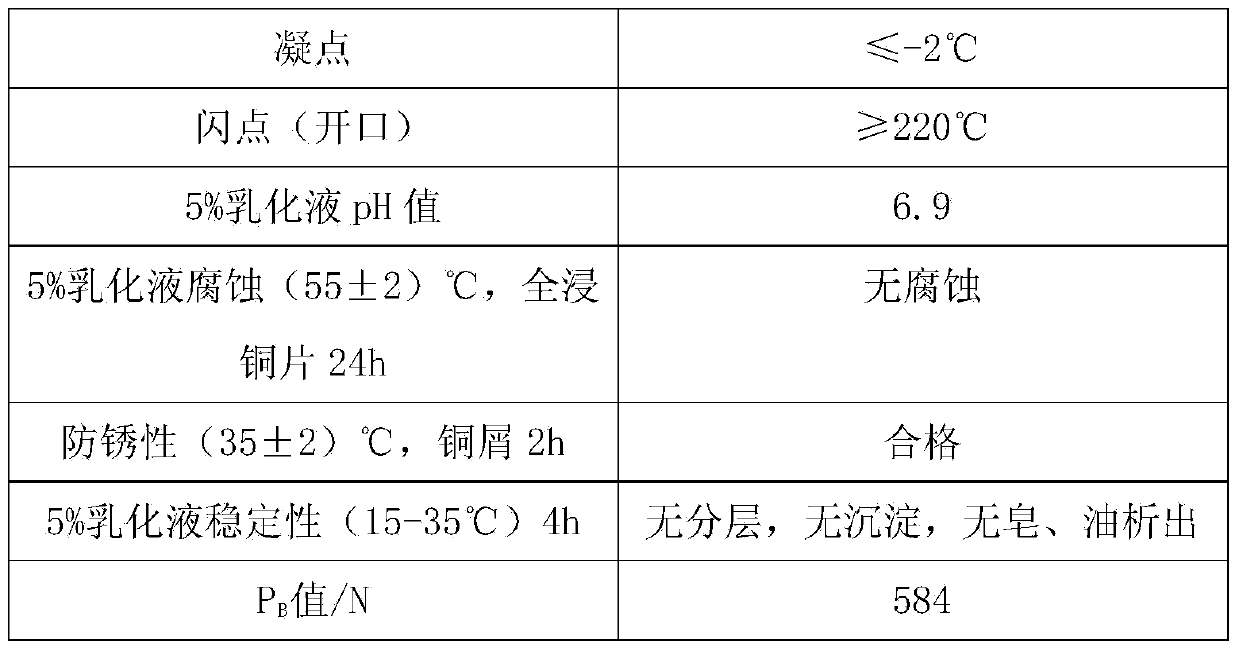

[0011] The drawing oil in this embodiment is made from the following raw materials in parts by weight (kg): coconut oil 100, fluorinated silicon oil 60, polyvinylpyrrolidone 0.02, isooctyl oleate 10, lecithin 8, gallic acid 0.2, glycerin 2, cyclic Zinc alkanoate 0.5, nonylphenol polyoxyethylene ether 0.5, chlorinated paraffin 1, auxiliary agent 3; the auxiliary agent is made of the following raw materials in parts by weight: butyl stearate 15, graphene 1, partial silicon Sodium phosphate 2, xanthan gum 10, polyoxyethylene lauryl ether 4, deionized water in an appropriate amount; the preparation method is: first add polyoxyethylene lauryl stearate and graphene to butyl stearate, and turn at 1500 rpm Stir down for 20 minutes to make an emulsion for subsequent use, then mix xanthan gum with an appropriate amount of deionized water to prepare a xanthan gum aqueous solution with a mass concentration of 70%, and finally mix the aqueous solution, emulsion and other remaining ingredien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com