Preparation method of high-purity and high-crystallinity titanium disulfide nanometer plates

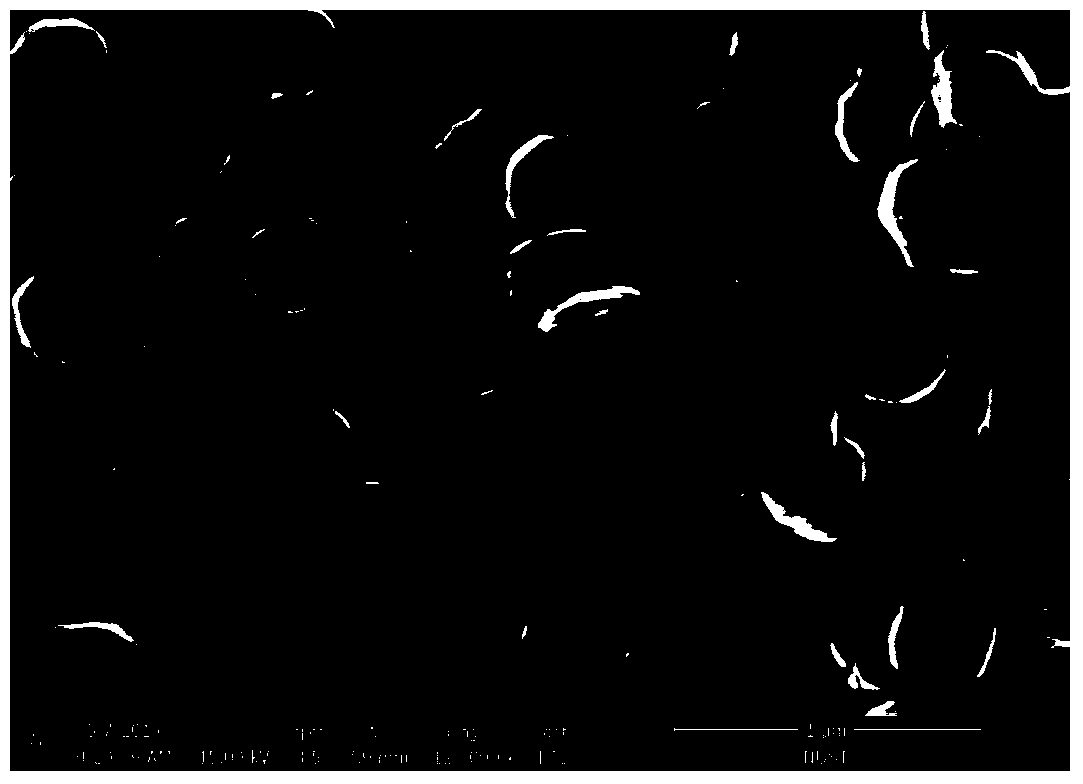

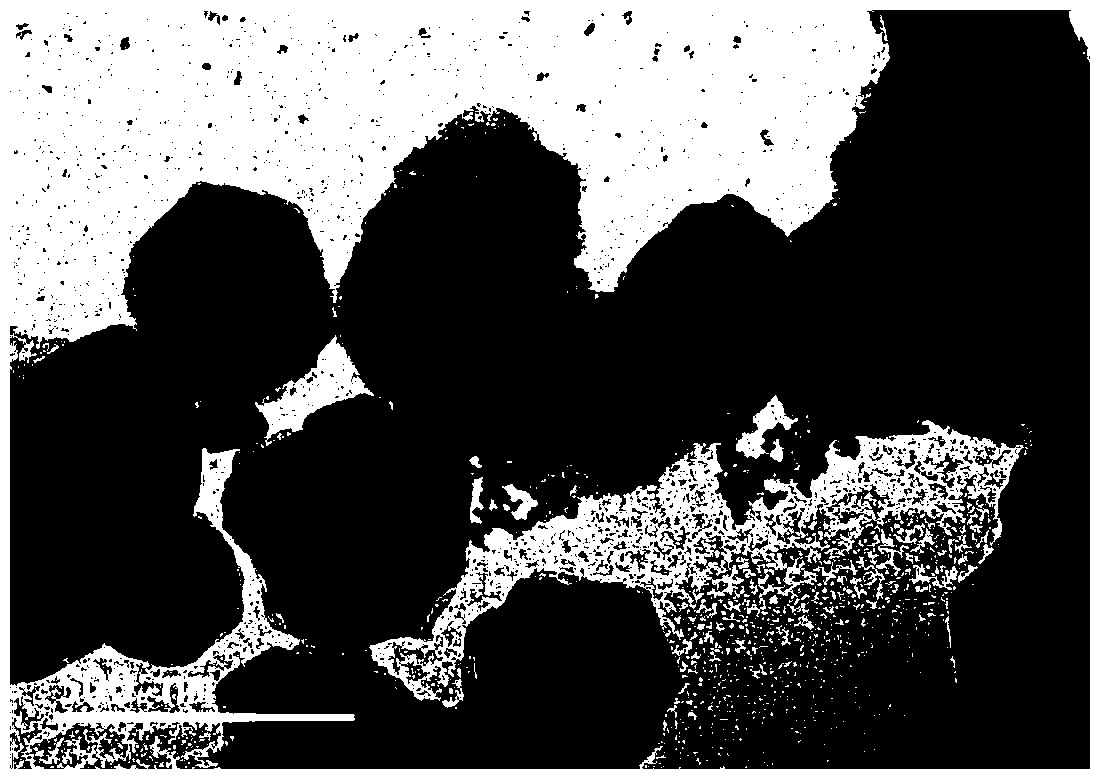

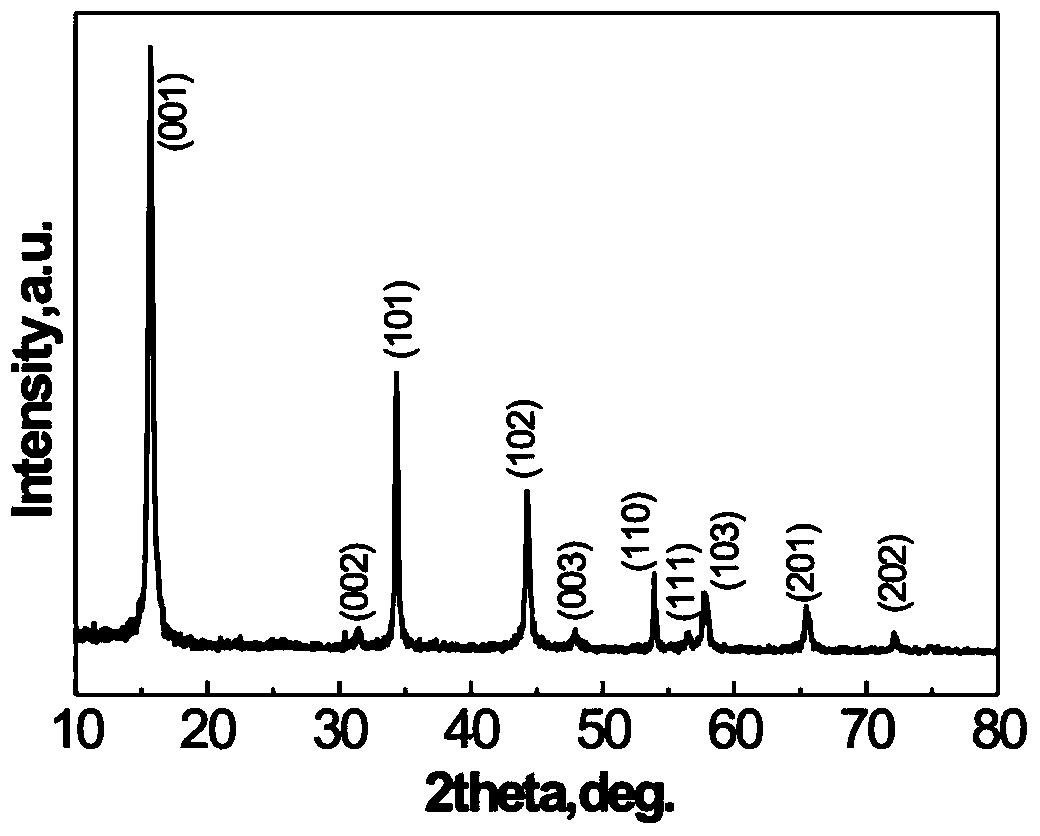

A titanium disulfide, high crystallinity technology, applied in the field of nanomaterials, can solve the problems of uneven size and shape of nanosheets, no two-dimensional sheet material characteristics, poor crystallinity of nanocrystals, etc. Uniform appearance, large-scale adjustment of size, easy-to-control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A two-step liquid-phase colloid synthesis method is adopted. In the first step, a titanium source and a surfactant are added to a container, heated to a certain temperature, stirred and mixed. In the second step, the sulfur source is injected, and the temperature is raised to the reaction temperature for a period of time to prepare TiS with uniform size and shape and high purity. 2 Nanosheets, the specific steps are as follows:

[0031] Step 1. Add 0.11ml TiCl to a 100ml four-neck flask 4 , 3.7ml oleylamine, 15ml octadecene, mixed and stirred.

[0032]Step 2. Raise the temperature to 100°C, pump air with a mechanical pump for 40 seconds, and then introduce Ar gas, and repeat this 10 times to remove impurities.

[0033] Step 3. Continue to raise the temperature to 180° C. and stir for 30 minutes to make the reactants evenly mixed.

[0034] Step 4. Inject CS into the container 2 , raised to 300°C, and kept warm for 3h.

[0035] Step 5, after the reaction ...

Embodiment 2

[0039] A two-step liquid-phase colloid synthesis method is adopted. In the first step, a titanium source and a surfactant are added to a container, heated to a certain temperature, stirred and mixed. In the second step, the sulfur source is injected, the temperature is raised to the reaction temperature and kept for a period of time, and high-purity TiS is prepared. 2 Nanosheets, the specific steps are as follows:

[0040] Step 1. Add 0.11ml TiCl to a 100ml four-neck flask 4 , 3.7ml oleylamine, 10ml octadecene, mixed and stirred.

[0041] Step 2. Raise the temperature to 120°C, pump air with a mechanical pump for 40 seconds, and then introduce Ar gas, repeating this 15 times to remove impurities.

[0042] Step 3. Continue to raise the temperature to 260°C, and stir for 20 minutes to make the reactants evenly mixed.

[0043] Step 4. Inject CS into the container 2 , raised to 270°C, and kept warm for 1h.

[0044] Step 5, after the reaction is over, remove the he...

Embodiment 3

[0048] A two-step liquid-phase colloid synthesis method is adopted. In the first step, a titanium source and a surfactant are added to a container, heated to a certain temperature, stirred and mixed. In the second step, the sulfur source is injected, the temperature is raised to the reaction temperature and kept for a period of time, and high-purity TiS is prepared. 2 Nanosheets, the specific steps are as follows:

[0049] Step 1. Add 0.11ml TiCl to a 100ml four-neck flask 4 , 3.7ml oleylamine, 20ml octadecene, mixed and stirred.

[0050] Step 2. Raise the temperature to 140°C, pump air with a mechanical pump for 40 seconds, and then introduce Ar gas, and repeat this 12 times to remove impurities.

[0051] Step 3. Continue to raise the temperature to 300° C. and stir for 20 minutes to make the reactants evenly mixed.

[0052] Step 4. Inject CS into the container 2 , raised to 310°C, and kept warm for 3h.

[0053] Step 5, after the reaction is over, remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com