Highly-porous separator film with a coating

A technology of porosity and coating, applied in the field of membrane preparation, can solve the problems of unsatisfactory mechanical strength, poor penetration resistance, high tearing tendency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0142] Preparation of the membranes mentioned in the examples:

[0143] Film Example 1

[0144] Calcium pimelate as a nucleating agent is copolymerized with isotactic polypropylene homopolymer (melting point 162°C; MFI3g / 10min), propylene homopolymer and propylene block in a mixer at a concentration of 0.04% by weight. The pellets formed were mixed and processed in a twin-screw extruder (shell temperature 240°C and 200 l / min -1 ) melted. After the extrusion process, the melt was extruded from a slot die at an extrusion temperature of 245°C to form a monolayer film.

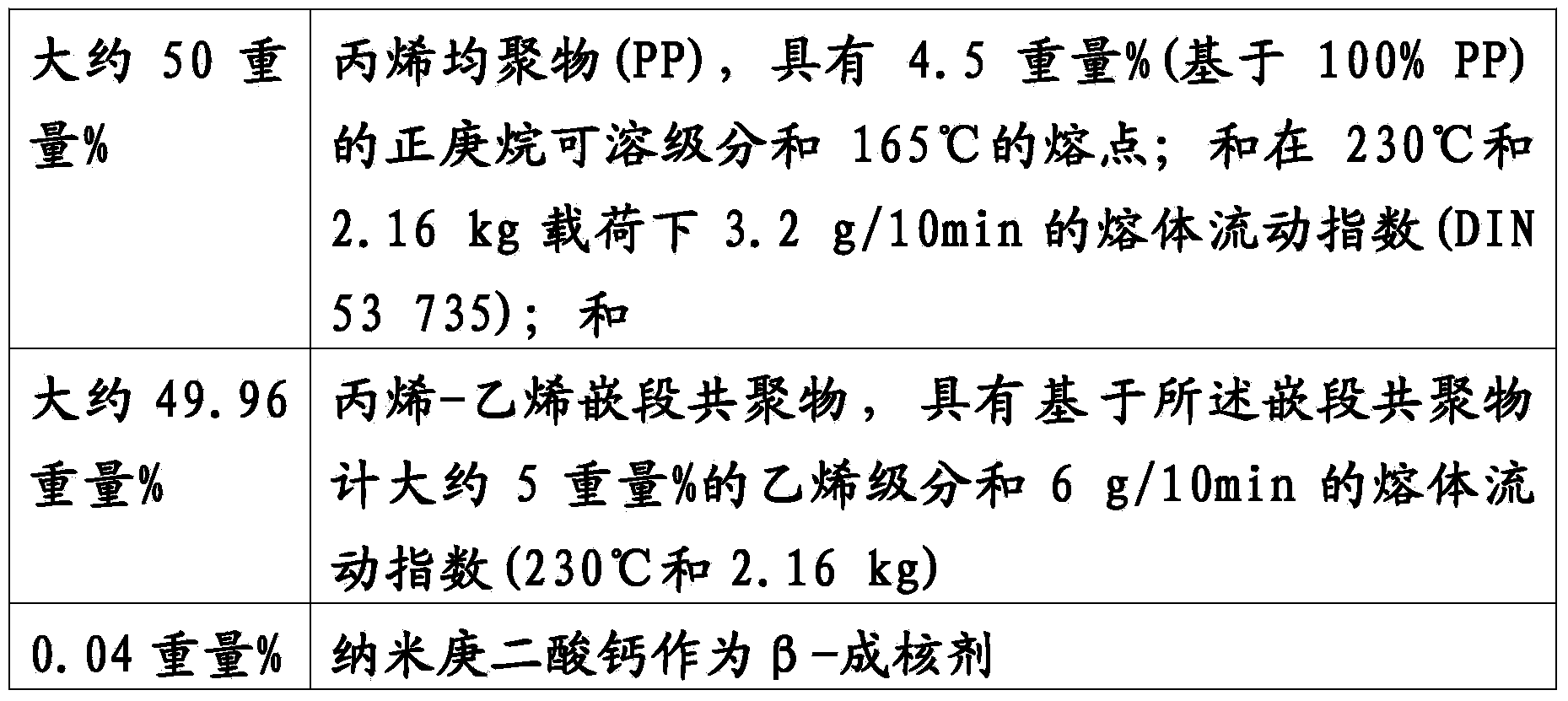

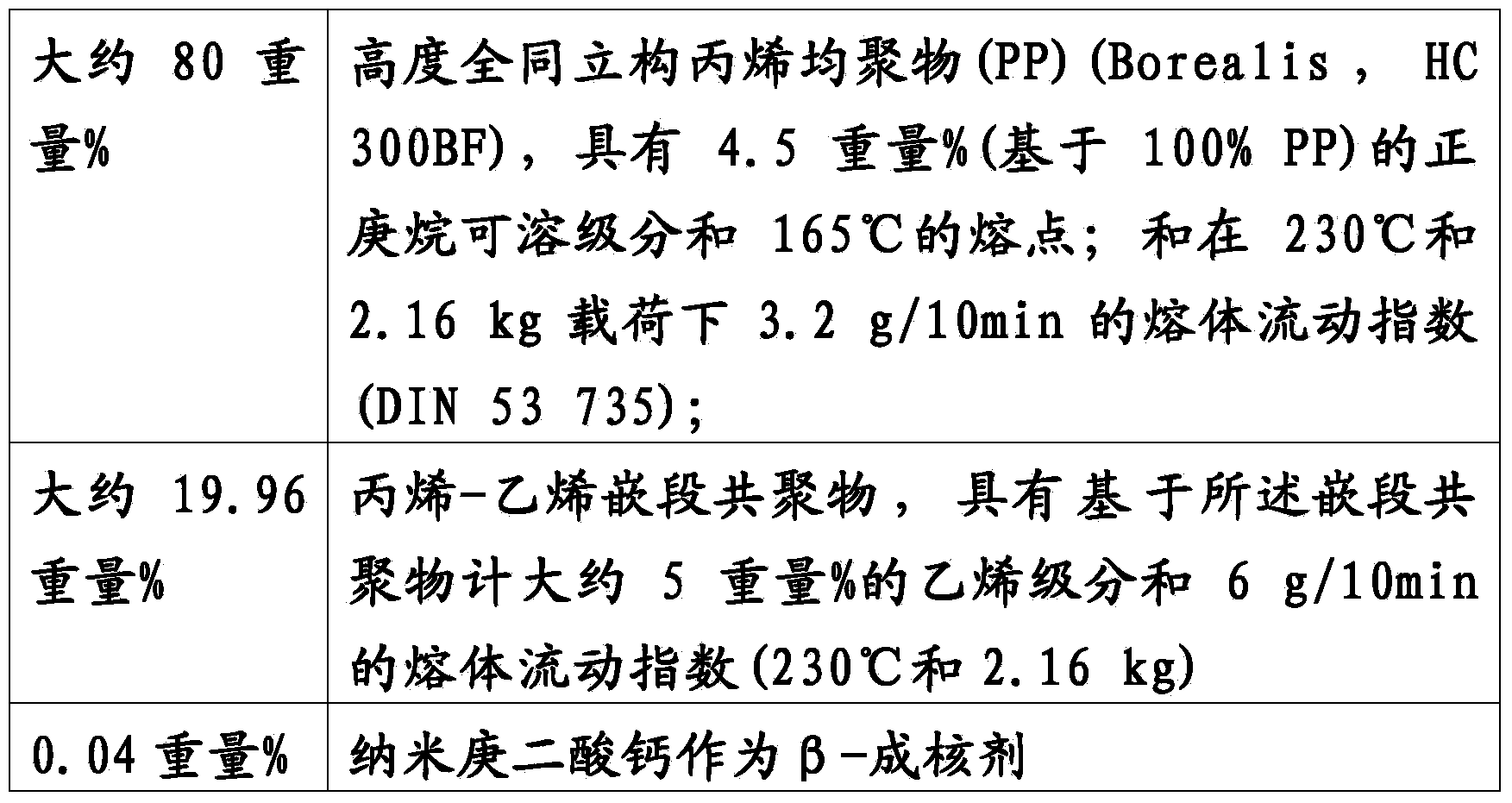

[0145] The membrane has the following composition:

[0146]

[0147] The film also contains conventional amounts of stabilizers and neutralizers.

[0148] After extrusion, the polymer mixture is drawn out on the first take-out roll and another three-roll set, cooled and solidified, then longitudinally stretched, transversely stretched and shaped, wherein the following conditions are specifically selected: ...

Embodiment 1

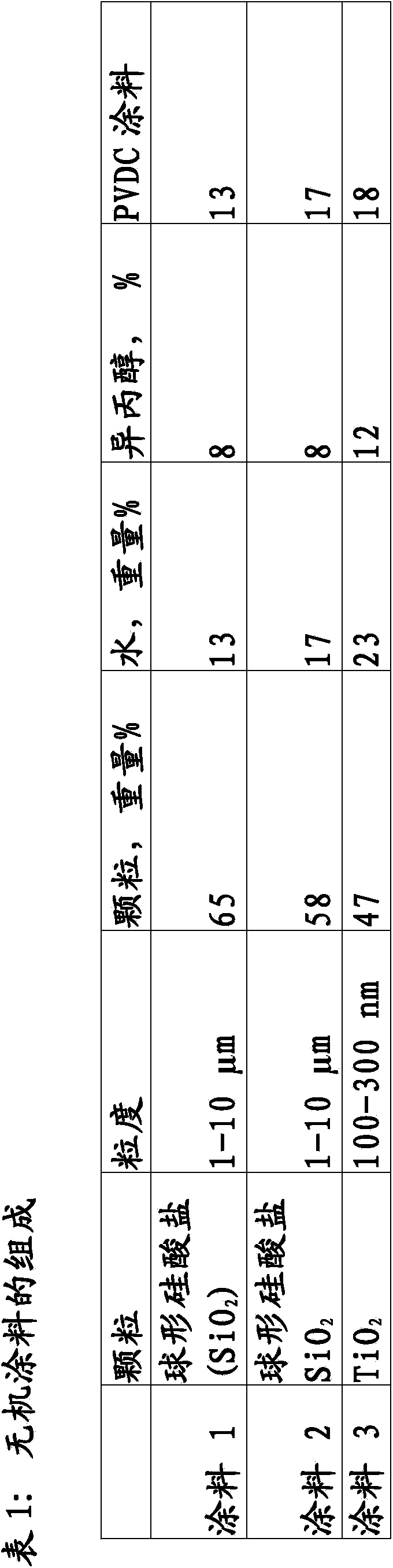

[0175] A silicate coating with the composition of Coating 1 (Table 1) was manually applied onto a microporous BOPP membrane (Membrane Example 1) using a wire knife coater (wire diameter: 0.4 mm). Wetting of the membrane with the ceramic suspension was uniform. The coated film was then dried in a drying oven at 90° C. for one hour. After drying, the coating showed good adhesion to the film. Next, the coating weight, the thickness of the coating layer and the permeability to air were determined using the Gurley value. Only a small increase in the Gurley value was observed, from 180s to 210s.

Embodiment 2

[0177] A silicate coating with the composition of Coating 2 (Table 1 ) was manually applied onto the microporous BOPP membrane (Membrane Example 1 ) using a wire knife coater (wire diameter: 0.4 mm). Coating Solution 2 differs from Coating 1 by a higher proportion of PVDC binder. After coating, the wetting of the membrane with the ceramic suspension was uniform. The coated film was dried again in a drying oven at 90° C. for one hour. After drying, the adhesion of the coating to the film was better than Example 1. In addition, the air permeability (Gurley value) is significantly improved for almost the same coating coat weight. Observe that the Gurley value increases from 180s to 420s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com