Preparation method of high-frequency bulk acoustic wave delay line transducer and high-frequency bulk acoustic wave delay line

A bulk acoustic wave and transducer technology, which is applied in the field of micro-acoustic thin film devices, can solve the problems of decreased production yield, excessive corrosion, and bottom electrode film corrosion in process preparation, so as to improve the production yield of process preparation, improve key and reliability, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

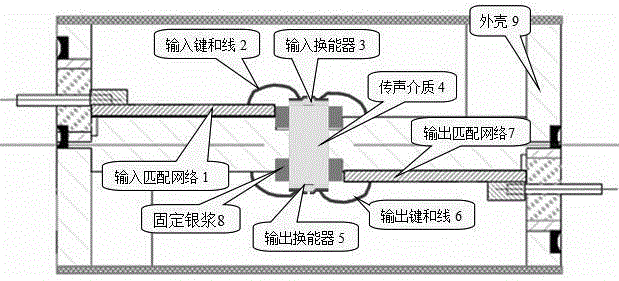

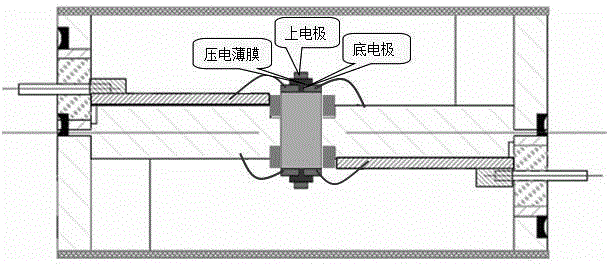

[0033] The high-frequency bulk acoustic wave delay line transducer of the present invention is a bottom electrode primer layer 2, a bottom electrode metal layer 3, a piezoelectric layer film 4, an upper electrode primer layer 5, and an upper electrode metal layer 6 formed at both ends of the sound transmission medium 1. .

[0034] Although the high-frequency bulk acoustic wave delay line transducer of the present invention also includes a bottom electrode, a piezoelectric film and an upper electrode, the preparation method is different, as follows:

[0035] 1) As shown in Figure 1A, a YAG material with a small sound transmission loss factor (0.6dB / μs1.5GHz) is selected as the sound transmission medium 1, and the YAG substrate is cleaned with a cleaning solution.

[0036] 2) As shown in Fig. 1B, deposit the bottom electrode primer layer 2 on both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com