A kind of antirust emulsified oil and preparation method thereof

A technology of anti-rust emulsified oil and engine oil, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of short anti-rust paint, long anti-rust period of anti-rust oil, and high cost, so as to prolong the anti-rust cycle and emulsify oil The effect of stable system and good emulsification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

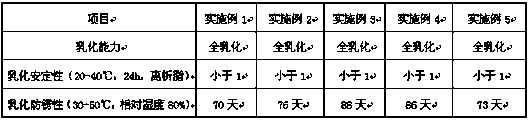

Examples

Embodiment 1

[0017] An antirust emulsified oil, comprising by weight components: 10 parts of barium petroleum sulfonate, 3 parts of sodium petroleum sulfonate, 8 parts of sulfonated oil DAH, 2 parts of triethanolamine, 0.5 part of glycerol, 0.2 part of emulsified silicone oil, 5 parts of zinc naphthenate, 2 parts of oleic acid, 1 part of sulfonated oleic acid, 70 parts of No. 10 motor oil.

[0018] The preparation method of antirust emulsified oil described above, prepares according to the following steps:

[0019] (1) Weigh each component according to parts by weight;

[0020] (2) Heat No. 10 engine oil to 80°C, then add barium petroleum sulfonate, sodium petroleum sulfonate, triethanolamine, and zinc naphthenate under the stirring condition of 50 rpm, and stir evenly to obtain a mixed solution;

[0021] (3) Cool the mixture obtained in step (2) to 60°C, add the remaining components, stir evenly at 60 rpm, and cool down to room temperature to obtain the anti-rust emulsified oil.

Embodiment 2

[0023] An anti-rust emulsified oil, comprising by weight components: 12 parts of barium petroleum sulfonate, 4 parts of sodium petroleum sulfonate, 11 parts of sulfonated oil DAH, 3 parts of triethanolamine, 1.2 parts of glycerol, 0.3 parts of emulsified silicone oil, 6 parts of zinc naphthenate, 3 parts of oleic acid, 2 parts of sulfonated oleic acid, 82 parts of No. 10 engine oil.

[0024] The preparation method of antirust emulsified oil described above, prepares according to the following steps:

[0025] (1) Weigh each component according to parts by weight;

[0026] (2) Heat No. 10 engine oil to 80°C, then add barium petroleum sulfonate, sodium petroleum sulfonate, triethanolamine, and zinc naphthenate under the stirring condition of 55 rpm, and stir evenly to obtain a mixed solution;

[0027] (3) Cool the mixture obtained in step (2) to 55°C, add the remaining components, stir evenly at 65 rpm, and cool down to room temperature to obtain the anti-rust emulsified oil.

Embodiment 3

[0029] A kind of antirust emulsified oil, comprising by weight components: 13 parts of barium petroleum sulfonate, 5 parts of sodium petroleum sulfonate, 12 parts of sulfonated oil DAH, 4 parts of triethanolamine, 1.5 parts of glycerol, 0.4 parts of emulsified silicone oil, 8 parts of zinc naphthenate, 4 parts of oleic acid, 3 parts of sulfonated oleic acid, 85 parts of No. 10 engine oil.

[0030] The preparation method of antirust emulsified oil described above, prepares according to the following steps:

[0031] (1) Weigh each component according to parts by weight;

[0032] (2) Heat No. 10 engine oil to 85°C, then add barium petroleum sulfonate, sodium petroleum sulfonate, triethanolamine, and zinc naphthenate under the stirring condition of 56 rpm, and stir evenly to obtain a mixed solution;

[0033] (3) Cool the mixture obtained in step (2) to 56°C, add the remaining components, stir evenly at 65 rpm, and cool down to room temperature to obtain the anti-rust emulsified o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com