Polycarboxylic acid cement grinding aid production method

A cement grinding aid and a production method technology, applied in the field of polycarboxylate cement grinding aid, can solve the problems of water change, instability, etc., and achieve the effects of good water, improve strength, and promote expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

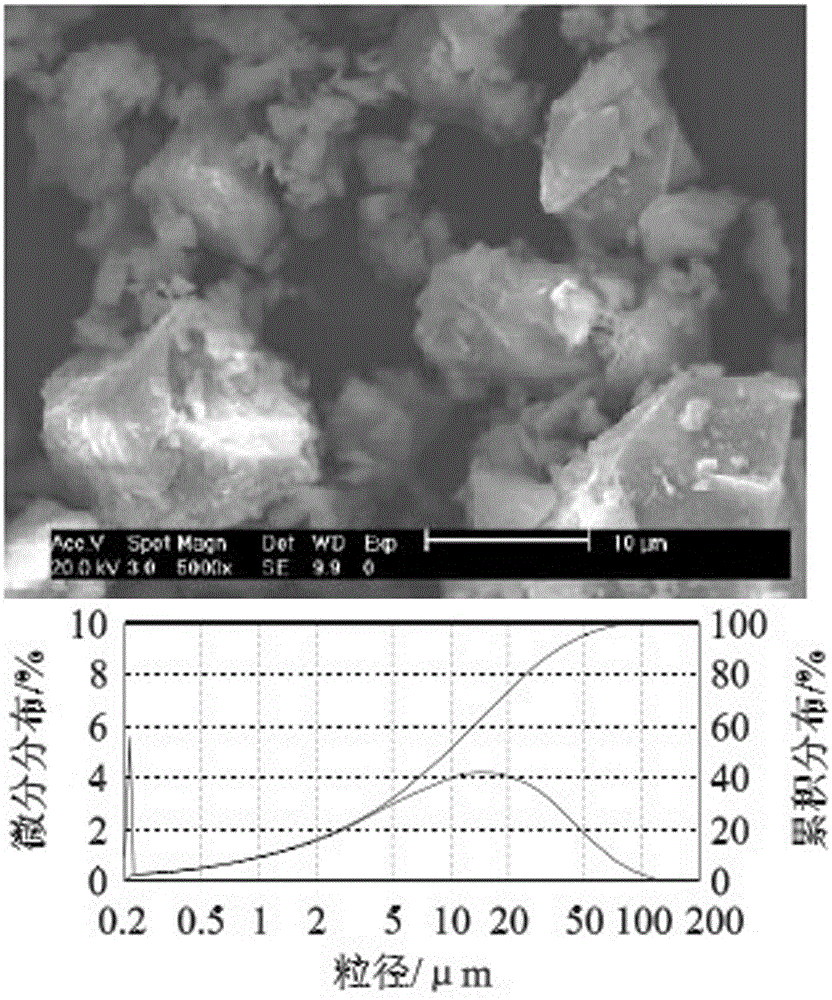

Embodiment 1

[0027] Add polycarboxylate cement grinding aid to cement grinding machine to produce cement and make cement powder.

[0028] Described polycarboxylate cement grinding aid is prepared by the following method:

[0029] ①Add maleic anhydride, ethylene glycol, polyethylene glycol, allyl polyethylene glycol, methacrylic acid, catalyst benzenesulfonic acid, polymerization inhibitor hydroquinone, initiator benzyl peroxide to the reaction kettle Acyl, stir and heat up to 65°C to make it undergo esterification reaction, maintain the reaction temperature for 2.5 hours, heat up to 100°C to make it undergo polymerization reaction, and obtain polycarboxylate cement grinding aid; the mass parts of each raw material are as follows: maleic anhydride 600, ethylene glycol 30, polyethylene glycol 30, allyl polyethylene glycol 100, methacrylic acid 60, catalyst benzenesulfonic acid 1 and polymerization inhibitor hydroquinone 1, initiator benzoyl peroxide 3 ;

[0030] 2. after the completion of ...

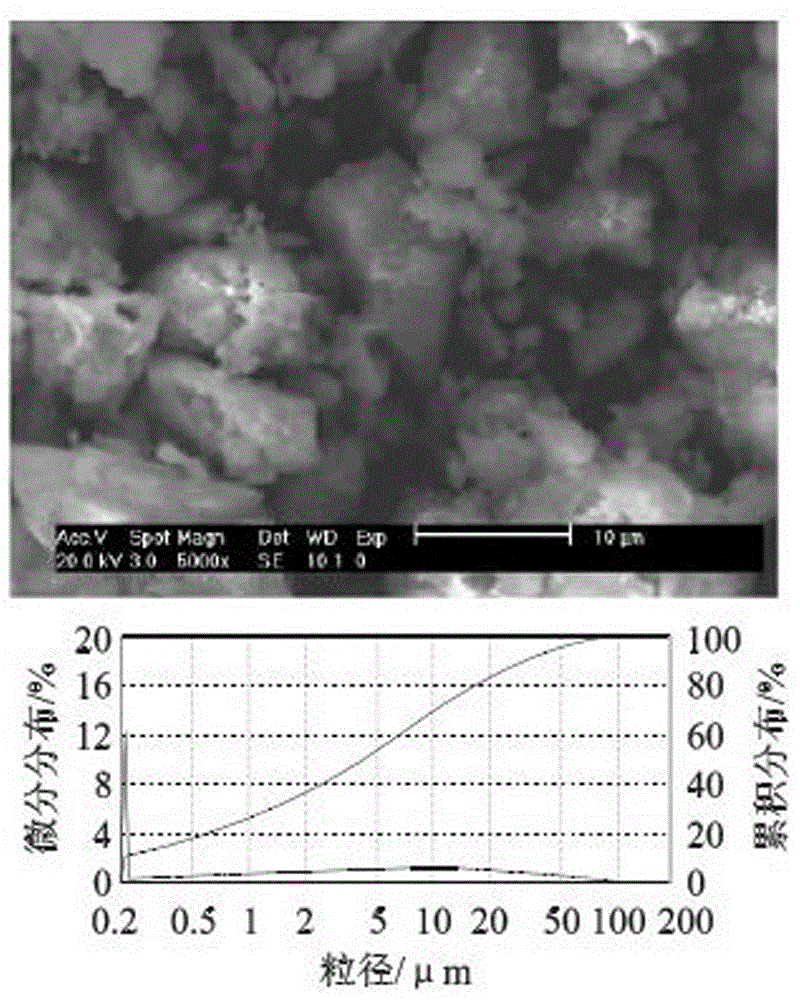

Embodiment 2

[0032] Add polycarboxylate cement grinding aid to cement grinding machine to produce cement and make cement powder.

[0033] Described polycarboxylate cement grinding aid is prepared by the following method:

[0034] ①Add maleic anhydride, ethylene glycol, polyethylene glycol, allyl polyethylene glycol, methacrylic acid, catalyst benzenesulfonic acid, polymerization inhibitor hydroquinone, initiator benzyl peroxide to the reaction kettle Acyl, stir and heat up to 70°C to make it undergo esterification reaction, maintain the reaction temperature for 2.5 hours, heat up to 110°C to make it undergo polymerization reaction, and obtain polycarboxylate cement grinding aid; the mass parts of each raw material are as follows: maleic anhydride 70. Ethylene glycol 40, polyethylene glycol 40, allyl polyethylene glycol 110, methacrylic acid 70, catalyst benzenesulfonic acid 3, polymerization inhibitor hydroquinone 3, initiator benzoyl peroxide 4 ;

[0035] 2. after completion of the reac...

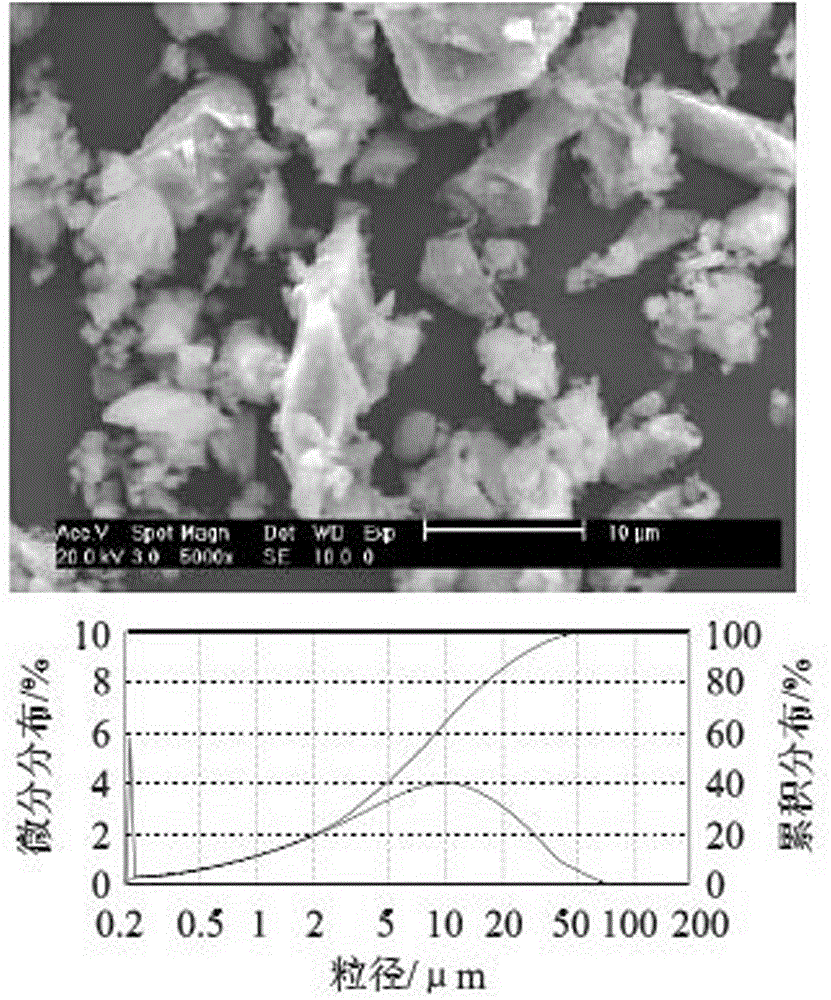

Embodiment 3

[0037] Add polycarboxylate cement grinding aid to cement grinding machine to produce cement and make cement powder.

[0038] Described polycarboxylate cement grinding aid is prepared by the following method:

[0039] ①Add maleic anhydride, ethylene glycol, polyethylene glycol, allyl polyethylene glycol, methacrylic acid, catalyst benzenesulfonic acid, polymerization inhibitor hydroquinone, initiator benzyl peroxide to the reaction kettle Acyl, stir and heat up to 75°C to make it undergo esterification reaction, maintain the reaction temperature for 3 hours, heat up to 120°C to make it undergo polymerization reaction, and obtain polycarboxylate cement grinding aid; the mass parts of each raw material are as follows: maleic anhydride 80, ethylene glycol 50, polyethylene glycol 50, allyl polyethylene glycol 120, methacrylic acid 80, catalyst benzenesulfonic acid 5 and polymerization inhibitor hydroquinone 5, initiator benzoyl peroxide 5 ;

[0040] 2. after completion of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com